Leakage detection method for liquid packaging apparatus

A technology of liquid encapsulation and leak detection, which is applied in the direction of measuring the rate of increase and deceleration of the fluid, using liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problems of instrument damage, instrument pollution, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

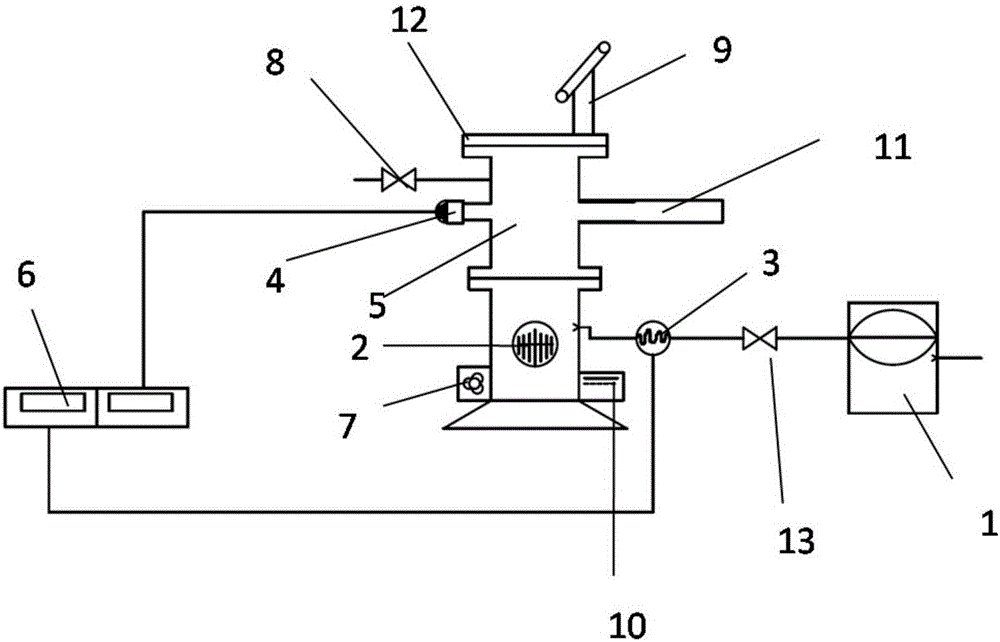

Image

Examples

Embodiment approach

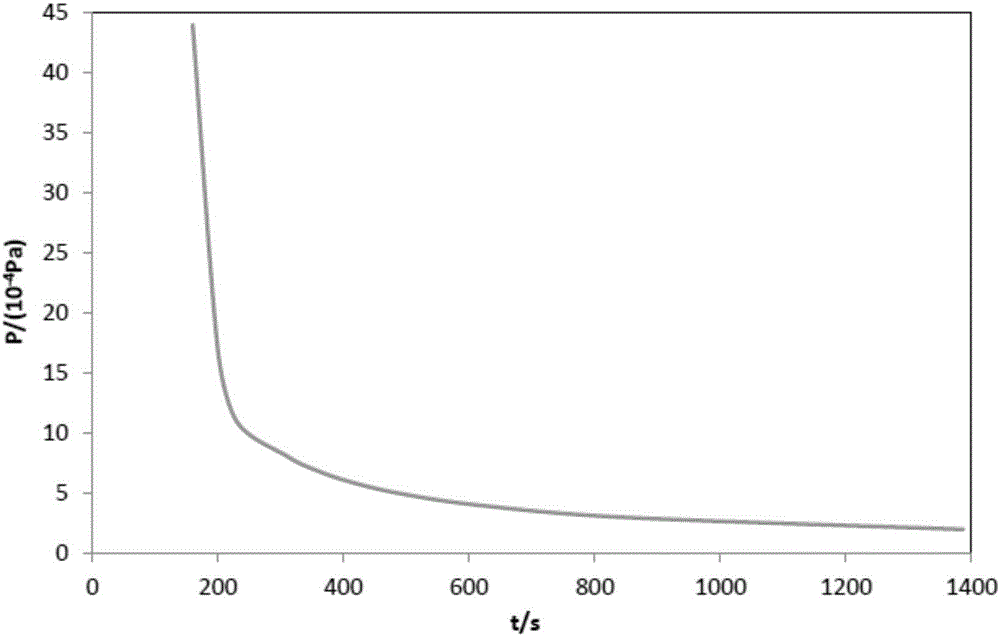

[0049] According to another embodiment of the present invention, if the limit pressure value P4 is equal to the limit pressure value P3, and the time T4 is greater than the time T3, then there is leakage in the liquid packaging device; if the limit pressure value P4 = limit pressure value P3, and the time If T4 is less than or equal to time T3, then there is no leakage in the liquid packaging device. When the leakage of the liquid encapsulation device is obvious, most of the leaked liquid is vaporized and volatilized before being placed in the sample chamber 5, and the liquid encapsulation device is basically in a dry state. Therefore, due to the liquid contained in the liquid encapsulation device If the amount is small, it may cause all the liquid to vaporize and be pumped out by the vacuum pump device, but the time to reach the ultimate pressure is relatively longer.

[0050] Further, if T4-T3≤180s, it is determined that the time T4 is equal to the time T3, and there is no l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com