Helium mass spectrometer leak detection method for sealing workpiece

A helium mass spectrometer leak detector and helium mass spectrometry technology are applied in the field of helium gas leak detection, which can solve problems such as low detection accuracy, and achieve the effects of high detection sensitivity, high leak detection accuracy and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

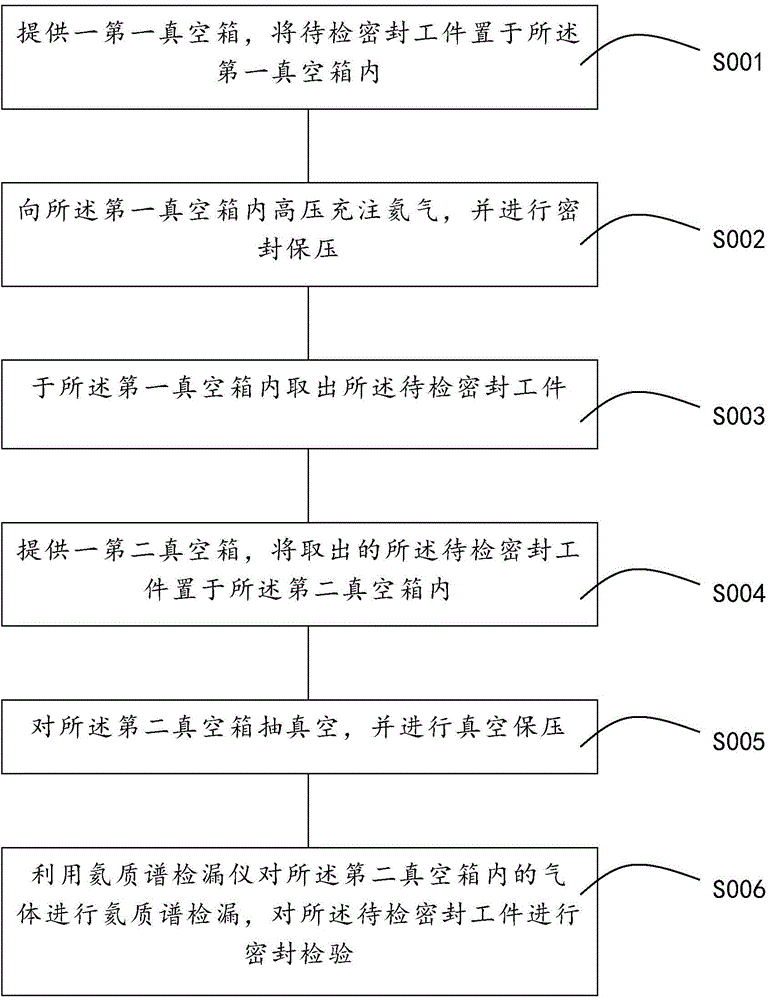

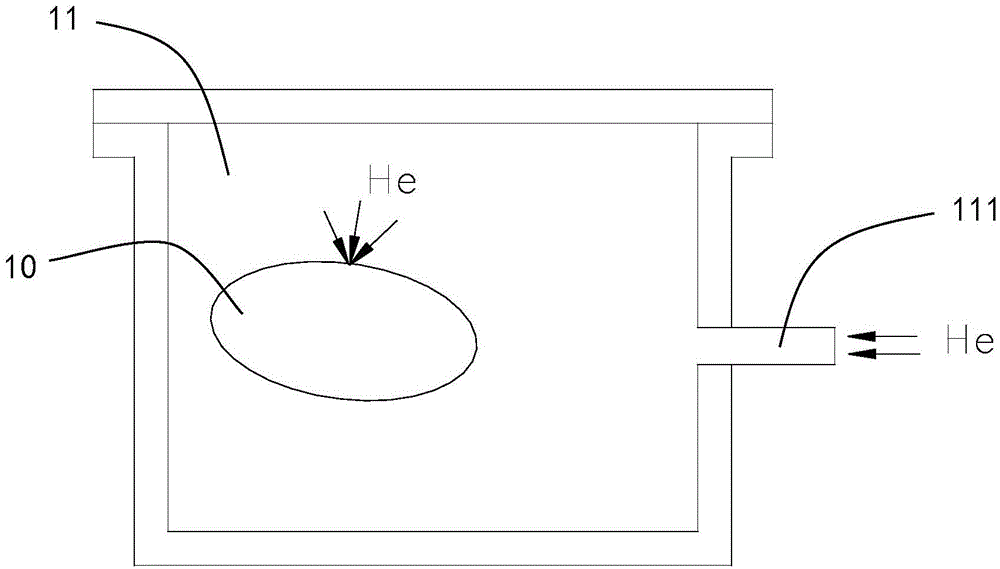

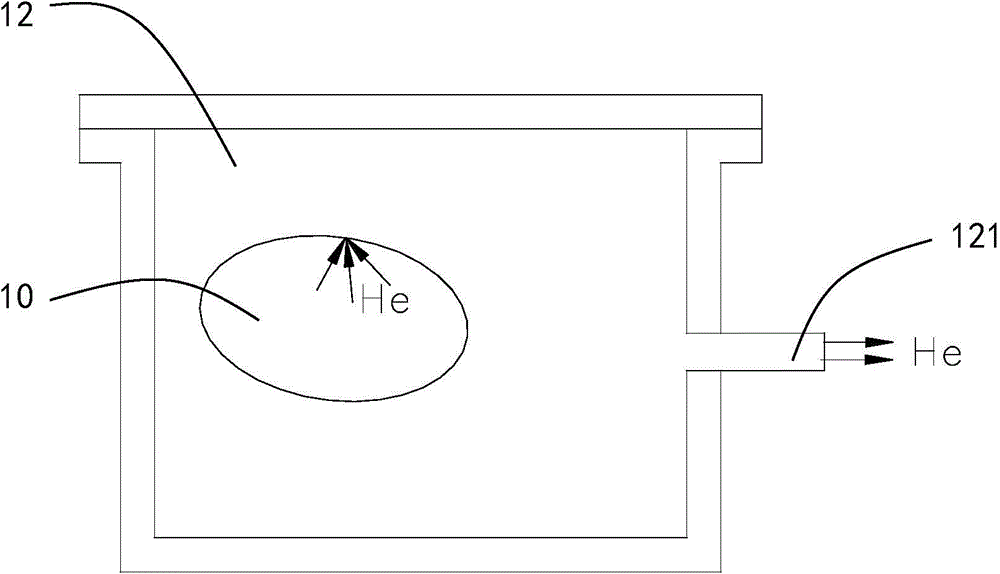

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The commonly used method for detecting leaks in completely closed containers is the pressure difference method. Put the closed container in a vacuum box, and after vacuuming, keep the pressure for a certain period of time. If the closed container leaks, the vacuum value will drop below a certain set value, but The detection accuracy of this leak detection method is low.

[0033] A helium mass spectrometry leak detection method for a sealed workpiece of the present invention adopts the detection method of pressing helium molecules into and out, which has the advantages of high detection sensitivity and high leak detection accuracy, and the helium-containing liquid used is set according to the pressure resistance requirements of the sealed container to be tested. The pressure value, the higher the pressure, the higher the leakage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com