Production method of heat-accumulation and heating bulked double-layered-structure yarn warm-keeping knitted fabric

A double-layer structure, knitted fabric technology, applied in the field of knitted fabric processing, can solve the problems of insufficient heat preservation effect, poor air permeability, affecting fabric texture and wearing comfort, etc., and achieve the effect of improving heat preservation effect, strength and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] 1. Warmth retention mechanism and characteristics of thermal storage and heating bulky double-layer structure yarn thermal insulation knitted fabrics

[0101] (1) Warmth retention mechanism of heat-storing heat-storing bulky double-layer structure yarn warm-keeping knitted fabrics

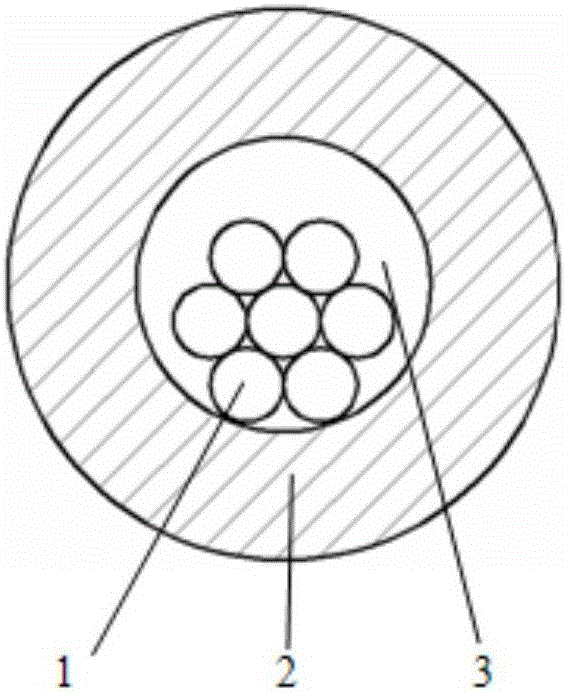

[0102] 1. The formation mechanism of thermal storage and heating bulky double-layer structure yarn

[0103] The overall structure of the yarn used in the present invention is a bulky double-layer hollow yarn.

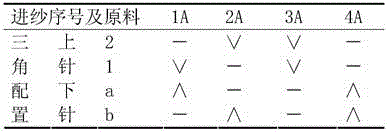

[0104] The first is spinning, which blends four short fibers of heat storage and heating fiber, regenerated cellulose fiber, water-soluble vinylon and high-shrinkage acrylic fiber into yarn.

[0105] The second is dimension reduction and puffing. The above-mentioned four-in-one blended yarn is treated with hot water to dissolve the water-soluble vinylon. At the same time, the high-shrinkage acrylic fiber also produces irreversible heat shrinkage, resulting in puffing effect, resultin...

specific Embodiment 1

[0207] Production method of heat-storing and heat-generating blended bulky double-layer structure yarns for thermal insulation knitted fabrics - skein yarn removal

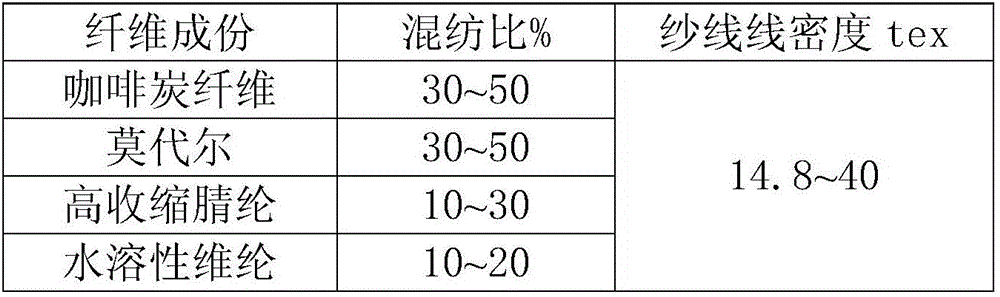

[0208] (1) Fiber raw material and mixing ratio

[0209] 1. Coffee charcoal fiber: specification 1.67dtex×38mm, mixing ratio: 30%

[0210] 2. Modal: specification 1.67dtex×38mm, mixing ratio: 40%

[0211] 3. High shrinkage acrylic fiber: specification 1.67dtex×38mm, mixing ratio: 15%

[0212] 4. Water-soluble vinylon: 1.67dtex×38mm, mixing ratio: 15%

[0213] (2) Yarn specifications

[0214] Yarn specification: 28tex

[0215] (3) Process flow

[0216] Package yarn→swinging yarn into skeins→dimensional removal (hot water puffing treatment at the same time)→cleaning→drying→winding→knitting→knitted fabric dyeing and finishing

[0217] (4) Dimension reduction and puffing process

[0218] 1. Hot water temperature: boiling water at 100°C;

[0219] 2. Bath ratio: 1:15;

[0220] 3. Hot water treatment time: 40min. ...

specific Embodiment 2

[0243] Production method of heat-storing and heat-generating blended bulky double-layer structure yarn warm-keeping knitted fabric-fabric dedimensionalization

[0244] (1) Fiber raw material and mixing ratio

[0245] 1. Coffee charcoal fiber: specification 1.67dtex×38mm, mixing ratio: 30%;

[0246] 2. Modal: specification 1.67dtex×38mm, mixing ratio: 40%;

[0247] 3. High shrinkage acrylic fiber: specification 1.67dtex×38mm, mixing ratio: 15%;

[0248] 4. Water-soluble vinylon: 1.67dtex×38mm, mixing ratio: 15%.

[0249] (2) Yarn specifications

[0250] Yarn specification: 28tex.

[0251] (3) Technological process - fabric return

[0252] Package yarn→knitting→dimensional removal (hot water treatment and puffing at the same time)→cleaning→knitted fabric dyeing and finishing

[0253] (4) Dimension reduction and puffing process

[0254] 1. Hot water temperature: boiling water at 100°C

[0255] 2. Bath ratio: 1:15

[0256] 3. Hot water treatment time: 40min.

[0257] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com