Koala velvet and production method thereof

A manufacturing method and koala velvet technology, applied in dyeing method, textile and paper making, liquid/gas/vapor removal by centrifugal force, etc., can solve the problems of high manufacturing cost, poor hand feeling, loose tissue structure, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Koala fleece 5mm single-sided material, finished product 152m×325g / m2, gram weight 500g / m2, the production steps are as follows:

[0057] 1. Raw material preparation: select and prepare raw materials, use 83DTEX36F (75D / 36F) Xiaoguang flat yarn as koala suede yarn, 56dtex polyester FDY (50D) as koala suede bottom yarn, among which 83DTEX36F Xiaoguang flat yarn Accounting for 75 parts by weight, 56dtex polyester FDY accounts for 25 parts by weight.

[0058] 2. Weaving: KS3 / 28E warp knitting machine produced by Karl Mayer in Germany is used for weaving. The weight of the gray cloth is 500g / m, and the width is 197cm, or according to the needs of customers.

[0059] 3. Heat setting: use a needle plate stenter setting car, the temperature is 230°C, the fan speed in the drying room is 1800 rpm, the fan in the exhaust room is fully turned on, the fiber heating time is 40s, and the oil volatilization loss accounts for about 1.5% of the fabric weight.

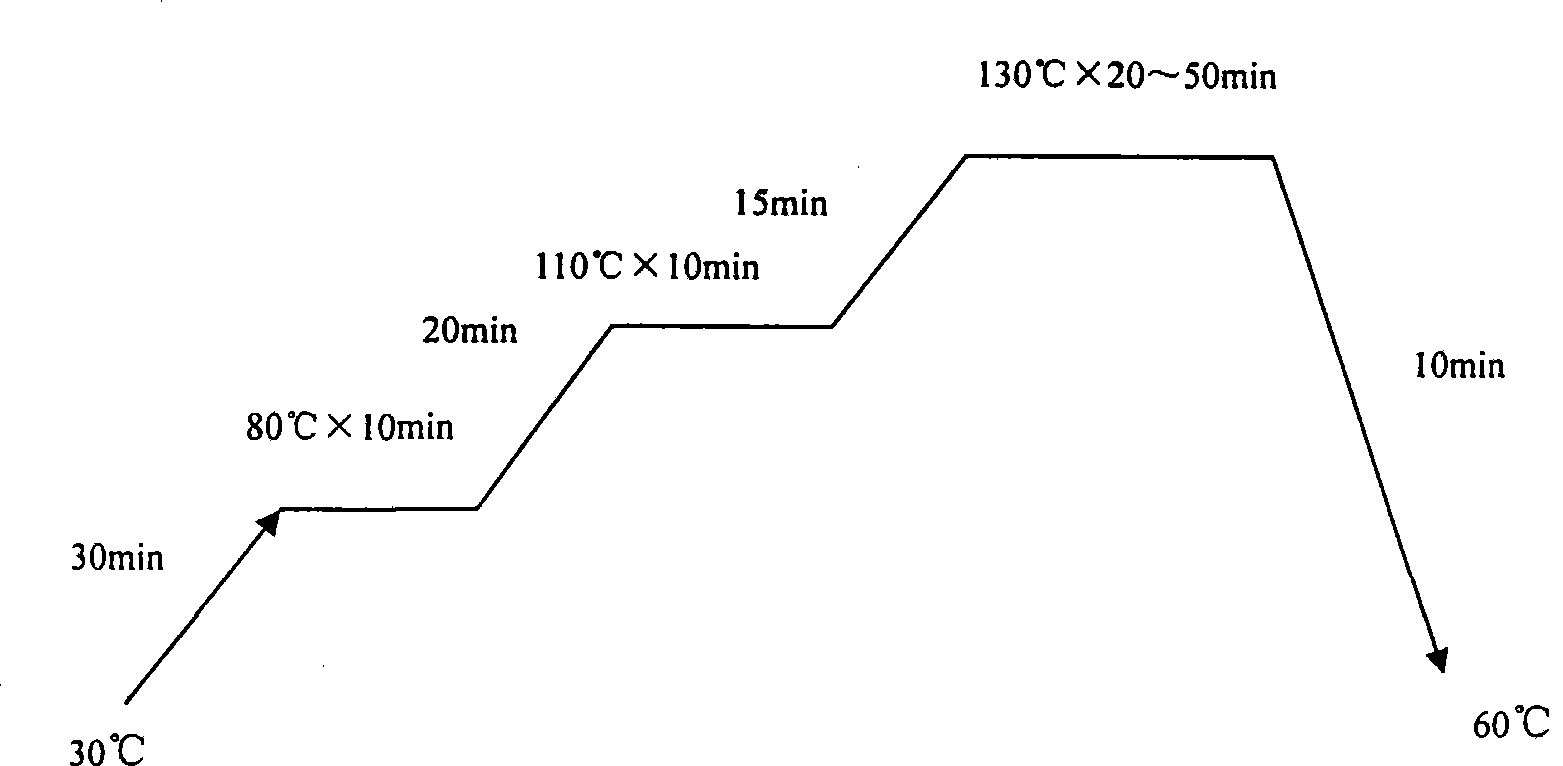

[0060] 4. Dyeing: The dy...

Embodiment 2

[0075] Koala fleece 2mm cationic two-color single-layer material, the finished product is 152m×325g / m2, and the weight is 500g / m2. The production steps are as follows:

[0076] 1. Raw material preparation: select and prepare raw materials, use 83dtex36F (75D / 36F) FDY cationic flat yarn: 36 parts by weight, 83dtex36F (75D / 36F) FDY Xiaoguang flat yarn: 36 parts by weight, 56dtex24F (50D / 24F) polyester FDY: 28 parts by weight.

[0077] 2. Weaving: KS3 / 28E warp knitting machine produced by Karl Mayer in Germany is used for weaving. The weight of the gray cloth is 500g / m, and the width is 197cm, or according to the needs of customers.

[0078] 3. Heat setting: use a needle plate stenter setting car, the temperature is 230°C, the fan speed in the drying room is 1800 rpm, the fan in the exhaust room is fully turned on, the fiber heating time is 40s, and the oil volatilization loss accounts for about 1.5% of the fabric weight.

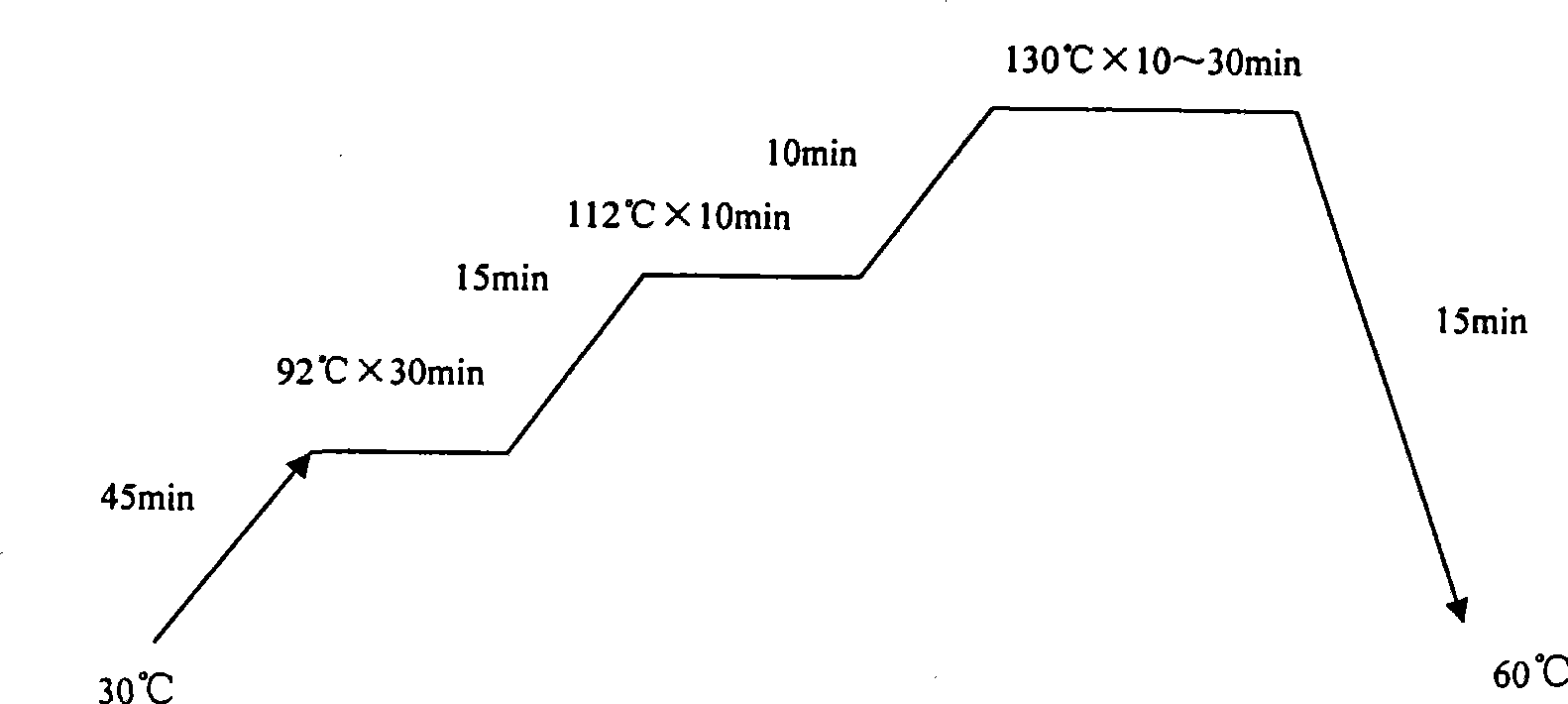

Embodiment 3

[0092] Koala fleece 7mm cationic double-sided material, finished product 152m×325g / m 2 , the double-layer weight is 550g / m, and its production steps are:

[0093] 1. Raw material preparation: select and prepare raw materials, use 56dtex36F FDY cationic flat yarn: 36 parts by weight, 56dtex36FFDY Xiaoguang flat yarn: 36 parts by weight, 56dtex24F polyester FDY filament: 28 parts by weight.

[0094] 2. Weaving: KS3 / 28E warp knitting machine produced by Karl Mayer in Germany is used for weaving. The weight of the gray cloth is 500g / m, and the width is 197cm, or according to the needs of customers.

[0095] 3. Heat setting: use a needle plate stenter setting car, the temperature is 210°C, the fan speed in the drying room is 1800 rpm, the fan in the exhaust room is fully turned on, the fiber heating time is 60s, and the oil volatilization loss accounts for about 1.5% of the fabric weight.

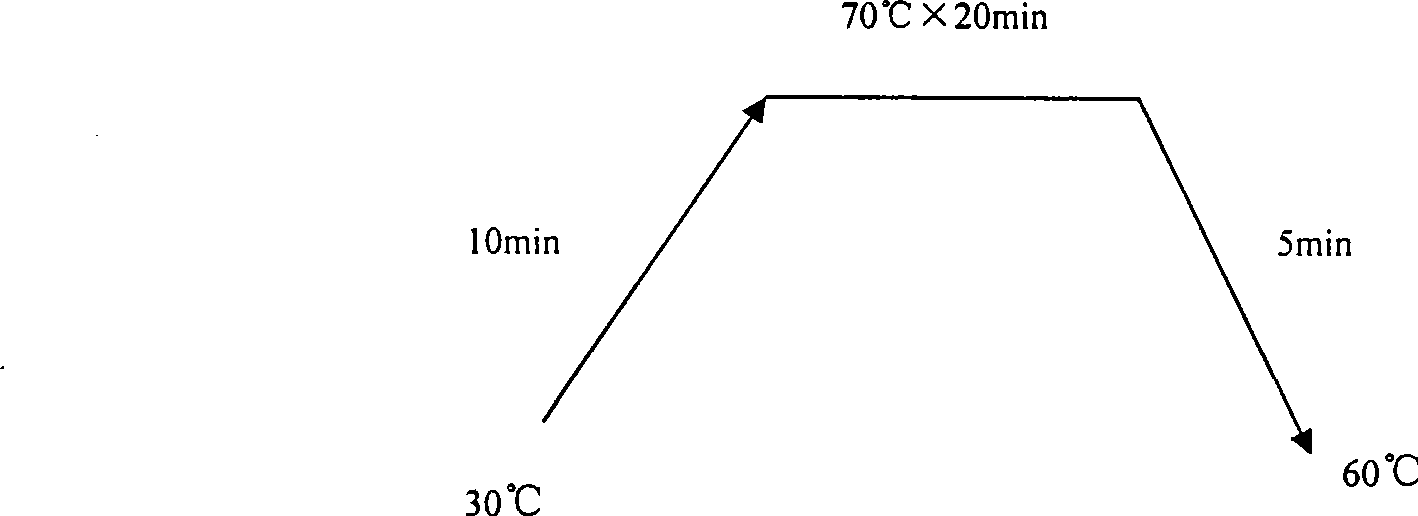

[0096]4. Dyeing: The dyeing machine is an overflow high temperature and high pressure dyein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com