Cheese dewatering machine

A dewatering machine and cheese yarn technology, which is applied in the direction of removing and treating textile material carriers with centrifugal force, etc. The effect of finished product forming quality, uniform stretching force and avoiding yarn deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

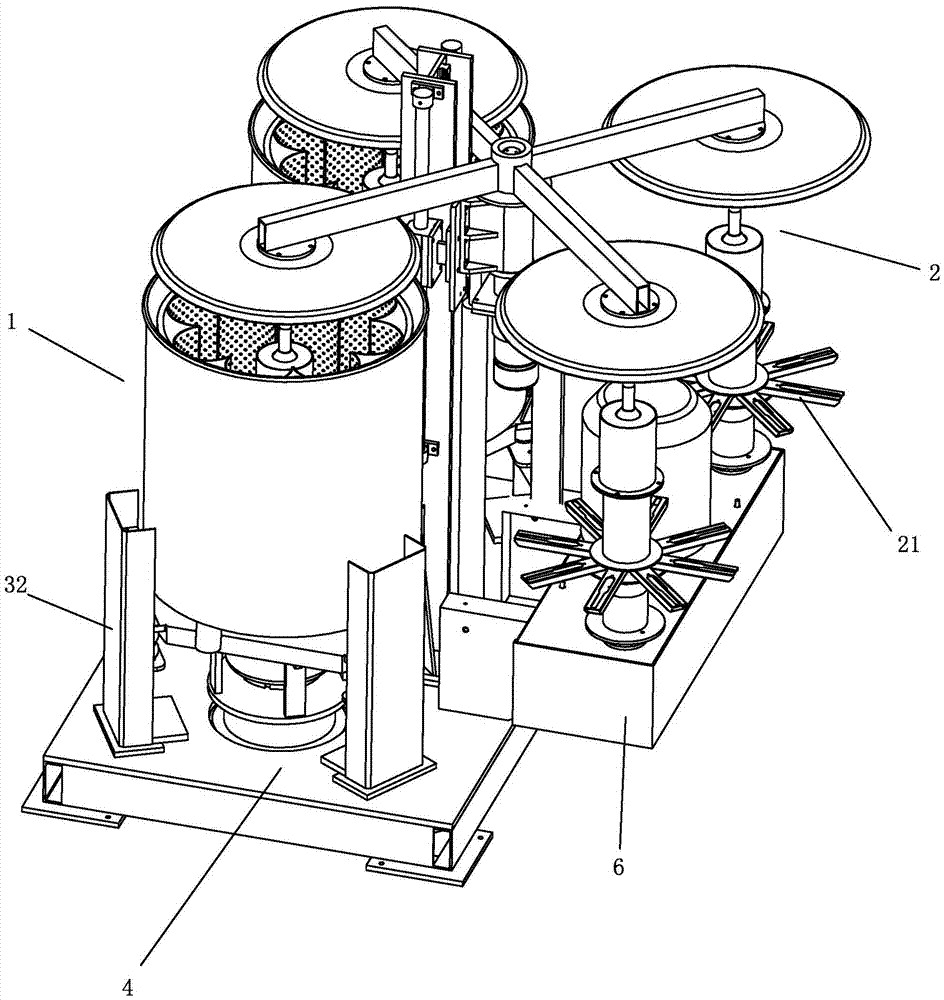

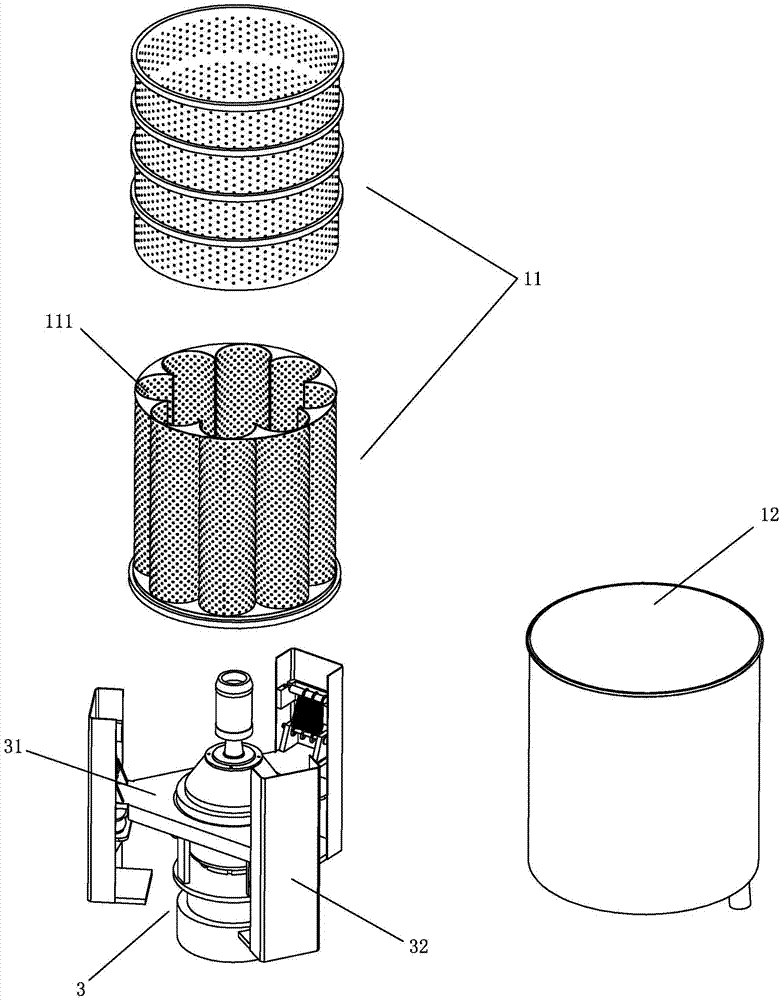

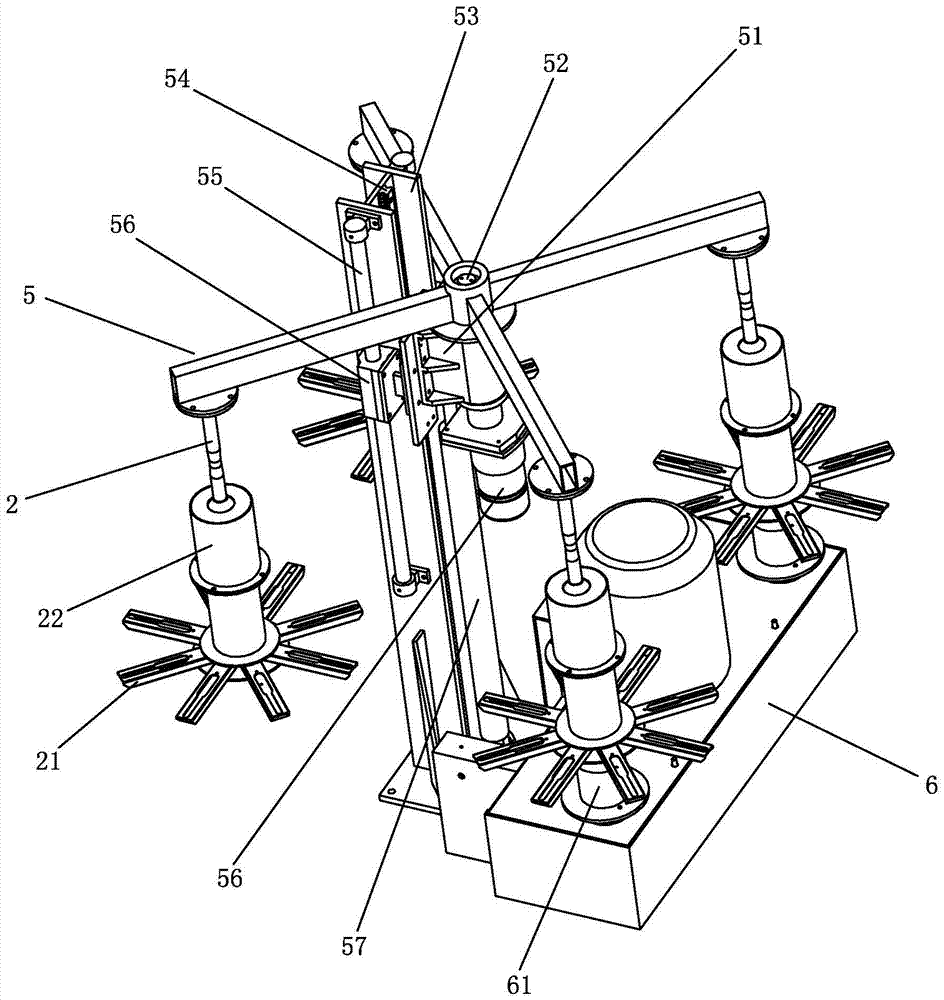

[0021] refer to Figure 1-Figure 4 , a cheese dehydrator of the present invention, comprising a dehydration barrel 1 and a hanger 2, the dehydration barrel 1 includes an inner container 11 driven by a driving mechanism and an outer barrel 12 corresponding to accommodate the inner container 11, the inner container 11 There are several grooves 111 that protrude radially from the barrel wall and match the cheese, and the barrel wall of the inner tank 11 is provided with many through holes for drainage. The hanger 2 can be placed in the dehydration barrel 1 And rotate with the inner container 11, the hanger 2 is provided with the bobbin creel 21 corresponding to the groove 111, the bobbin is placed on the bobbin creel 21 and put into the inner container 11 along with it, and the inner container is driven by the driving mechanism. The gallbladder 11 rotates rapidly with the yarn bobbin to realize rapid dehydration.

[0022] As an improvement of the above-mentioned embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com