Dehydrator

A dewatering machine, shell technology, applied in textile processing machine accessories, textiles and papermaking, liquid/gas/vapor removal by centrifugal force, etc., to achieve the effect of low loss rate, long brake service life, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

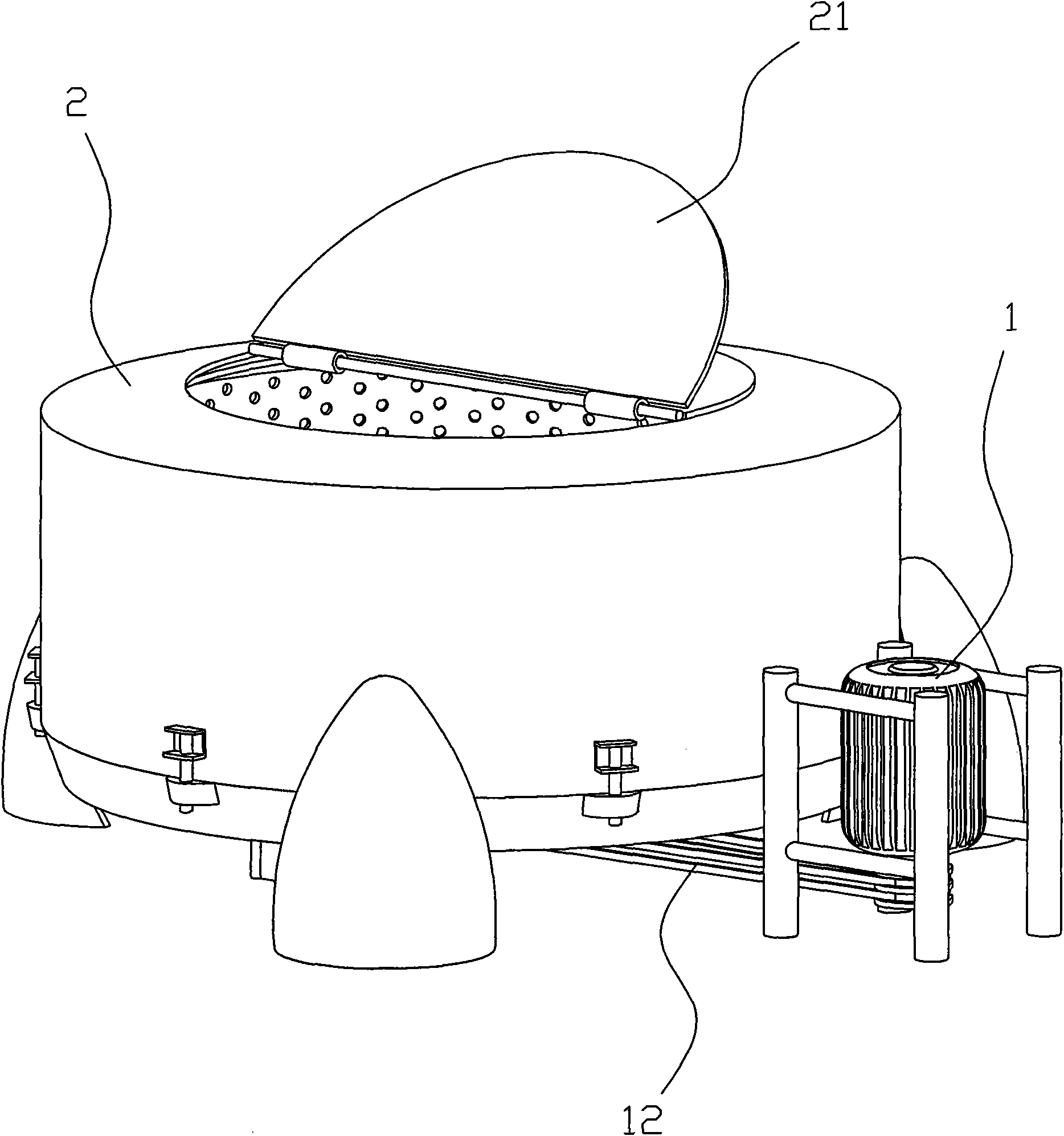

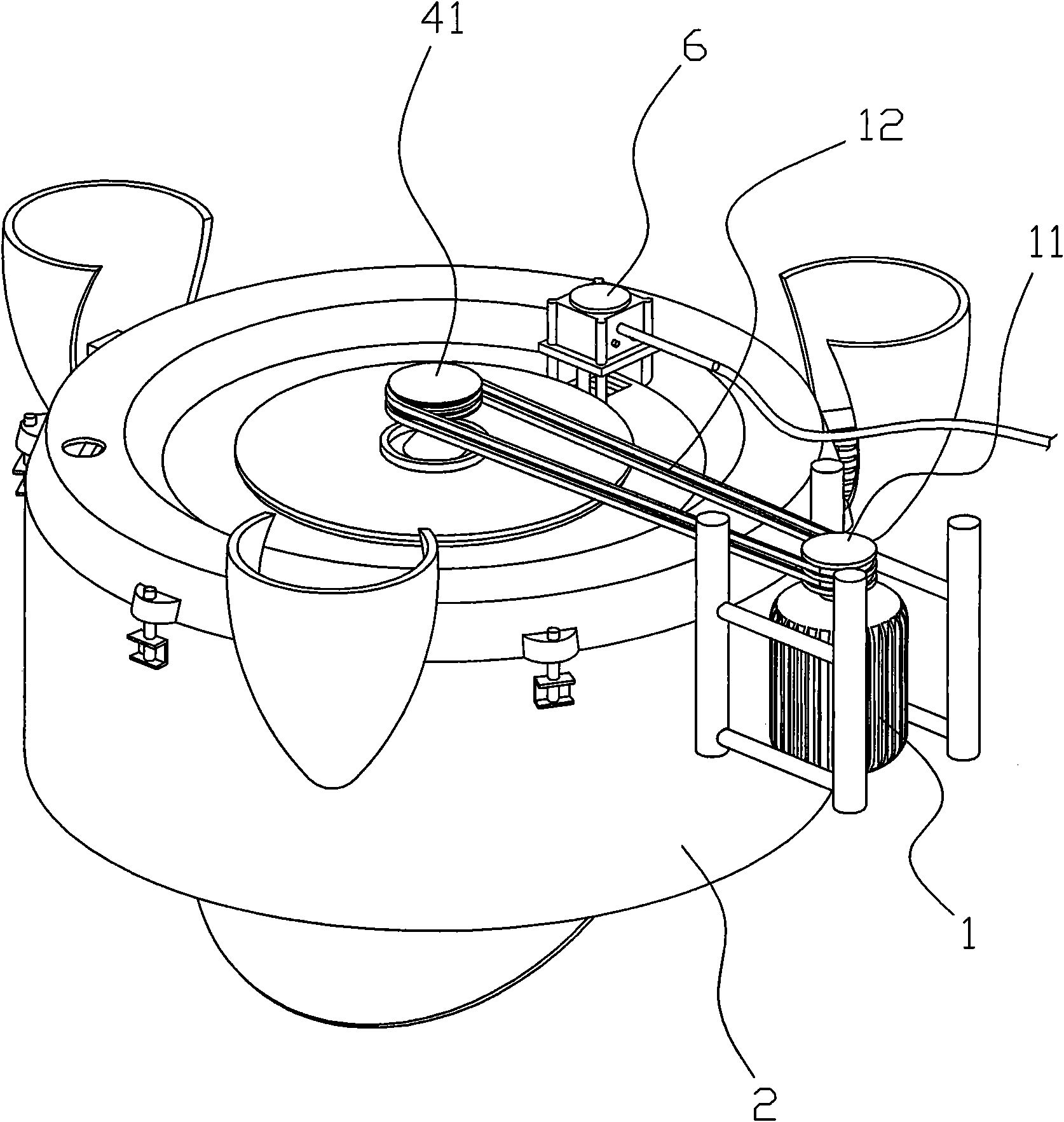

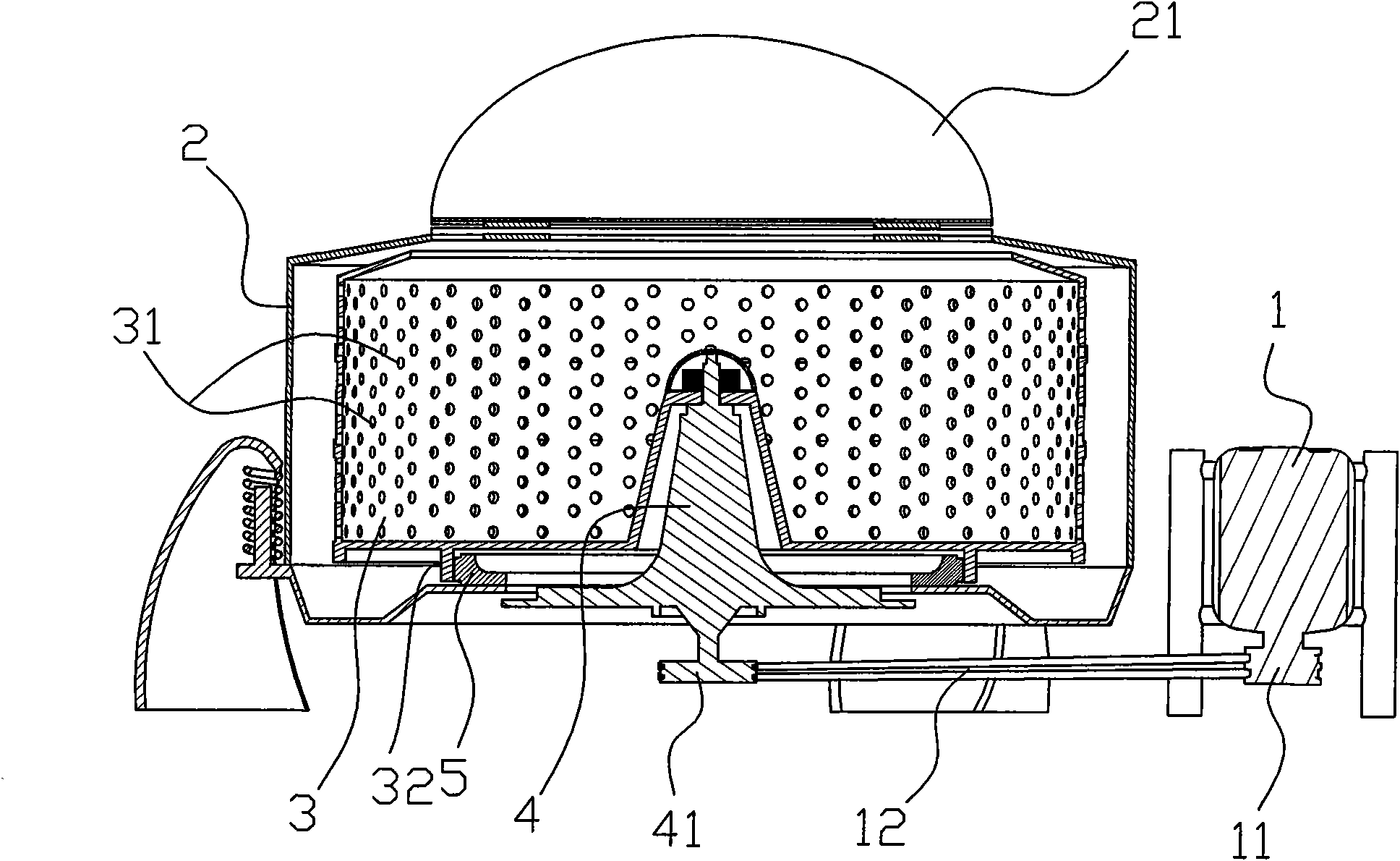

[0020] Such as Figure 1 to Figure 8 As shown, the dehydrator in this embodiment includes a casing 2 and a drum 3 with through holes 31 distributed on the sides, and an openable and closable cover plate 21 is provided at the top opening of the casing 2 . The rotating drum 3 is rotatably arranged in the casing 2, and the rotating drum 3 is connected with the output shaft of the motor 1 arranged outside the casing 2 through a transmission device, and the tops of the rotating drum 3 and the casing 2 are respectively provided with openings. An annular brake ring 32 extends downwards from the lower surface of the bottom of the drum 3, and an expandable and contractible annular brake rail 5 is arranged on the bottom of the casing 2. The outer surface of the annular brake rail 5 is tightened The ring-shaped brake pad 51 is pasted and fixed. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com