Energy-saving-type cloth cleaning system for spinning

A cleaning system, energy-saving technology, applied in the field of textile production, can solve the problems of insufficient energy utilization, limited spraying range of nozzles, increased power consumption, etc., to achieve the effect of less power, better effect and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

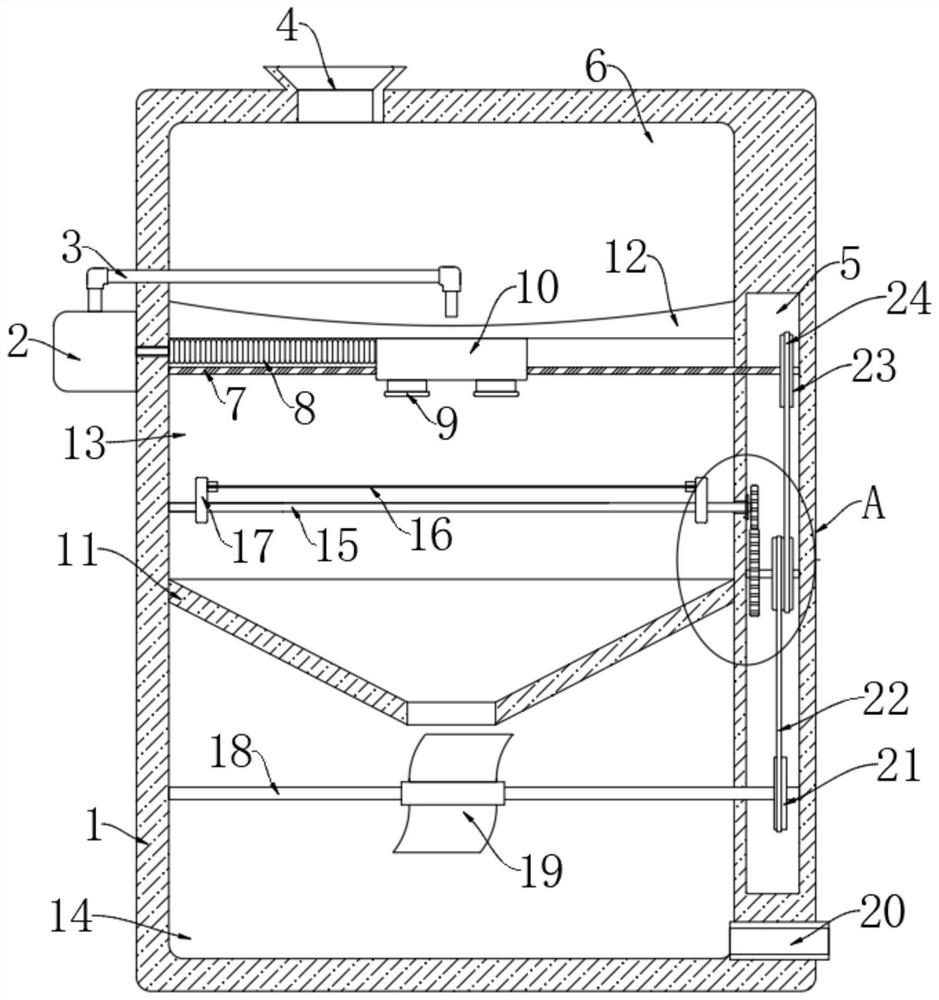

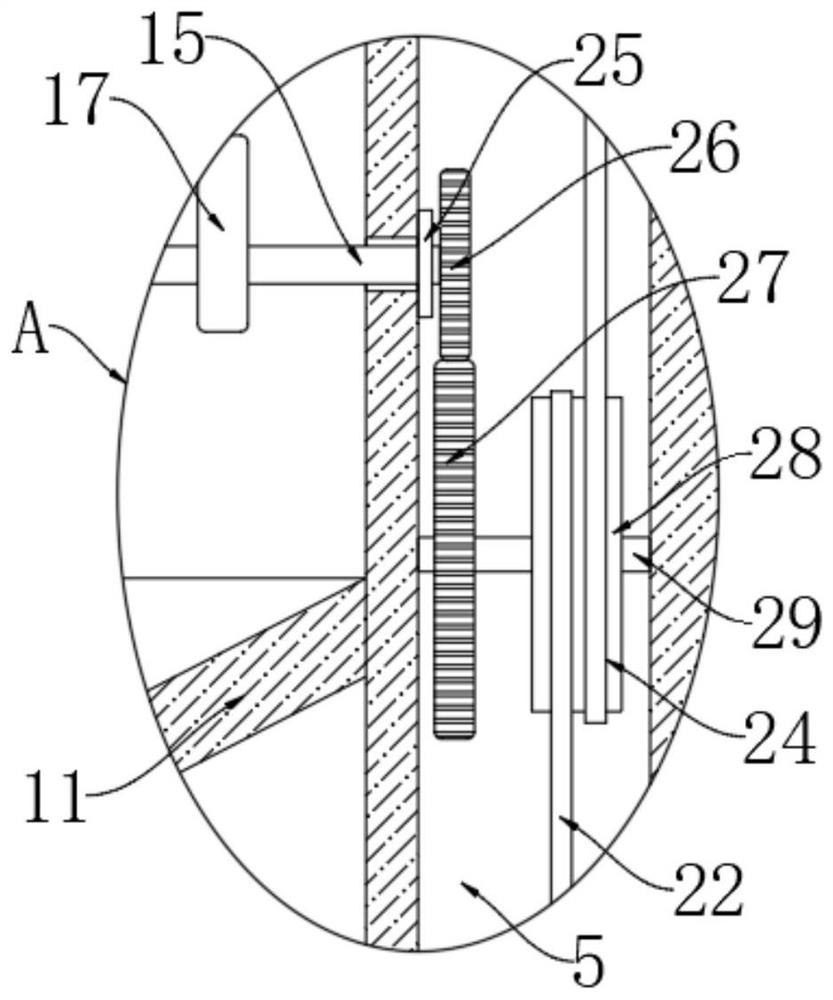

[0025] refer to Figure 1-4 , an energy-saving textile cloth cleaning system, comprising:

[0026] The box body 1 has a hollow cavity inside the box body, and the bottom plate 12 and the conical plate 11 are arranged in the hollow cavity sequentially from top to bottom, and the hollow cavity is divided into a water storage chamber 6 by the bottom plate 12 and the conical plate 11 , processing chamber 13 and water falling chamber 14, water storage chamber 6 is positioned at the top of processing chamber 13, and water falling chamber 14 is positioned at the below of processing chamber 13, and the inner top of water storage chamber 6 is provided with water inlet 4, and one side of water falling chamber 14 is opened There is a water outlet 20, a strip-shaped cavity 5 is provided in one side of the inner wall of the box body 1, and an airtight door 30 is installed on the front side of the box body 1;

[0027] Spraying mechanism, the spraying mechanism comprises the reciprocating s...

Embodiment 2

[0036] refer to Figure 5-6 The difference between this embodiment and Embodiment 1 is that the injection structure includes a mounting groove 32 arranged at the lower end of the moving block 10, and the mounting groove 32 is provided with two nozzles 9 which are rotatably connected. The two telescopic airbags 33 are connected, the right side of the moving block 10 is connected with the right inner wall of the processing chamber 13 through the first telescopic airbag 31, and the first telescopic airbag 31 and the second telescopic airbag 33 are communicated through a communication pipe.

[0037] In this embodiment, when the moving block 10 moves left and right, it will drive the first telescopic airbag 31 to stretch and compress. Stretching and compression will drive the second flexible air bag 33 to shrink and expand, that is, when the moving block 10 is moving, the two spray heads 9 are always in a swinging state, so that the spraying range is larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com