Device and method for cone yarn fixation aftertreatment

A post-processing device and package yarn technology, which is applied in the direction of liquid/gas/steam processing transmission device, liquid/gas/steam processing of a certain length of textile materials, textile material processing, etc., can solve problems such as uneven color fixation, To achieve the effect of improving the color fixing effect and uniform liquid retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

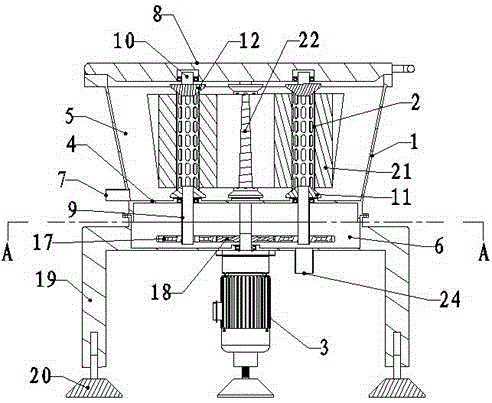

[0032] The steps of using the package yarn fixation post-processing device of embodiment one:

[0033] A. Install the bobbin yarn between the active bobbin shaft 9 and the driven bobbin shaft 10, start the drive motor 3, the driving motor 3 drives the active bobbin shaft 9 to rotate, the active bobbin shaft 9 drives the bobbin to rotate, and the yarn 21 Dehydration under the action of centrifugal force;

[0034] B. Start the negative pressure equipment. The negative pressure equipment sequentially passes through the negative pressure chamber 6, the active bobbin shaft 9 and the bobbin 2 to pump air inside the yarn 21, so that the alkaline solution of the part of the yarn 21 away from its mandrel is refluxed to the center , so that the liquid-carrying rate of each part of the yarn 21 is uniform.

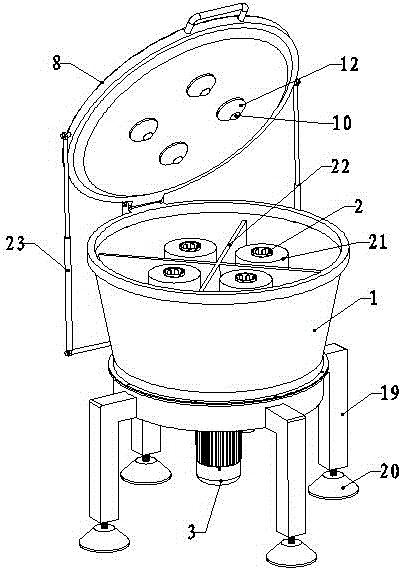

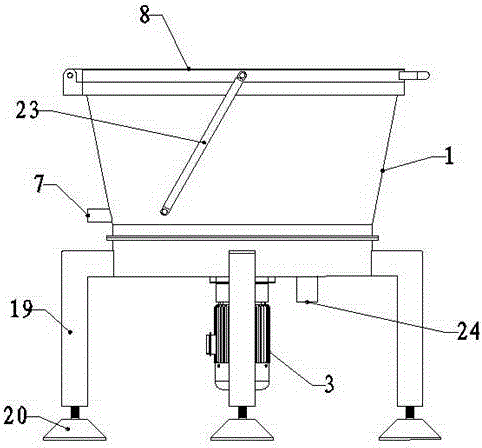

[0035] Figure 5~Figure 7 The second embodiment of the present invention is shown. As shown in the figure, a package yarn fixation post-processing device includes a barrel body 1 , ...

Embodiment 2

[0040] The use steps of the package yarn fixing post-processing device of embodiment two comprise the following steps:

[0041] A, cheese is installed on the bobbin rotating shaft 13, start drive motor 3, driving motor 3 drives bobbin rotating shaft 13 to rotate, and bobbin rotating shaft 13 drives bobbin to rotate, and yarn 21 is dehydrated under the effect of centrifugal force;

[0042] B, start the negative pressure equipment, the negative pressure equipment passes through the negative pressure chamber 6, the yarn bobbin rotating shaft 13 and the yarn bobbin 2 in turn to draw air inside the yarn 21, so that the alkaline solution of the part of the yarn 21 away from its mandrel is refluxed to the center, In order to make the liquid carrying rate of each part of the yarn 21 uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com