Printing and dyeing cloth dehydrator

A dewatering machine and cloth technology, which is applied in the direction of processing textile material equipment configuration, removing liquid/gas/vapor by centrifugal force, etc., can solve the problems of reducing the dewatering efficiency of the dewatering machine, unable to recycle water and liquid, and having impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

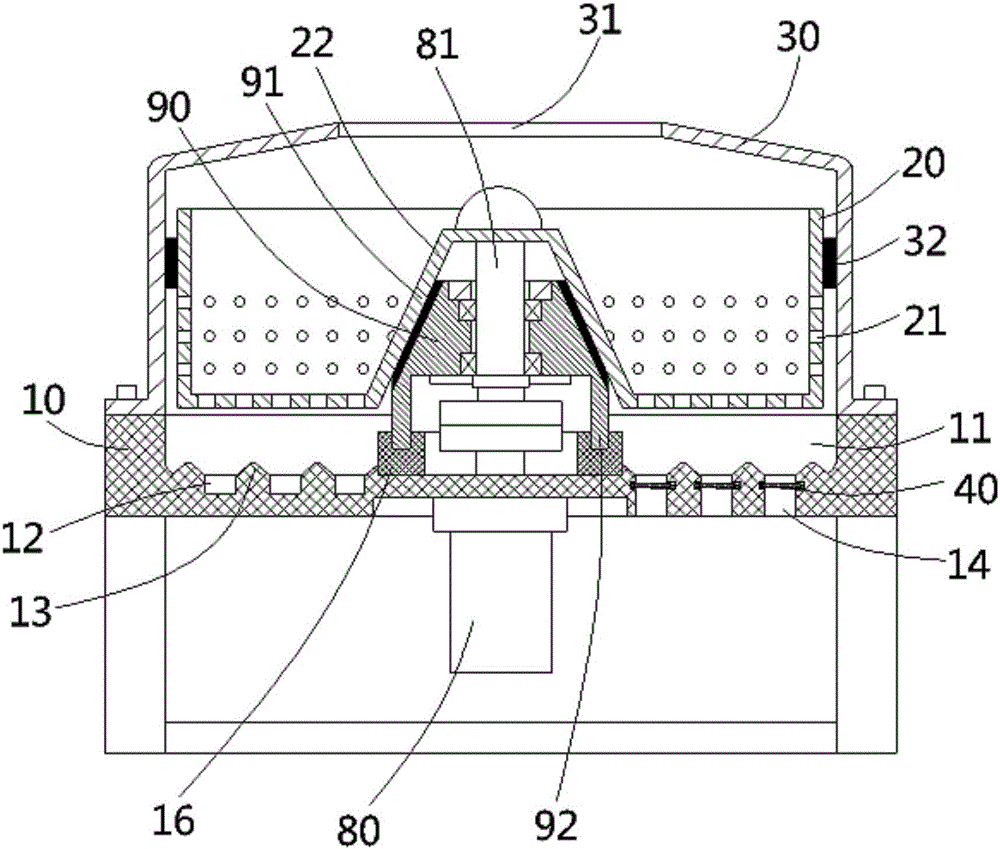

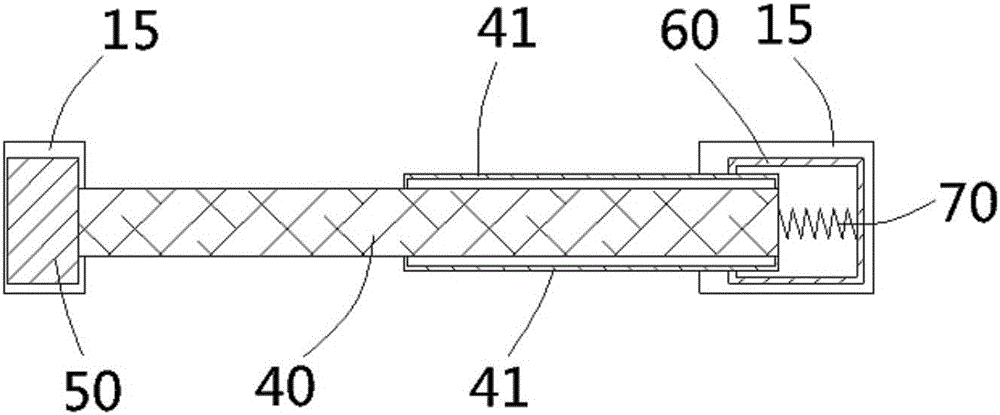

[0021] see figure 1 , a dehydrator device for printing and dyeing cloth according to the present invention, comprising a base 10, the top surface of the base has a groove 11, the groove is provided with a dehydration bucket 20, and the top surface of the base 10 is fixed There is a cylindrical protective cover 30, the top surface middle part of the cylindrical protective cover has a vertical placement through hole 31, the inner side wall of the cylindrical protective cover 30 is fixed with an annular wear ring 32, the dehydration bucket 20 is inserted into the annular wear-resistant ring 32 , the outer wall of the dehydration bucket 20 is close to the inner wall of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com