Rotating drum for cheese dewatering

A technology of package yarn and rotary cage, which is used in centrifugal force liquid/gas/vapor removal, textile and papermaking, textile processing machine accessories, etc., can solve the problems of high production cost, easy flattening of package yarn, and high energy consumption. , to achieve the effect of reducing moisture content and improving dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

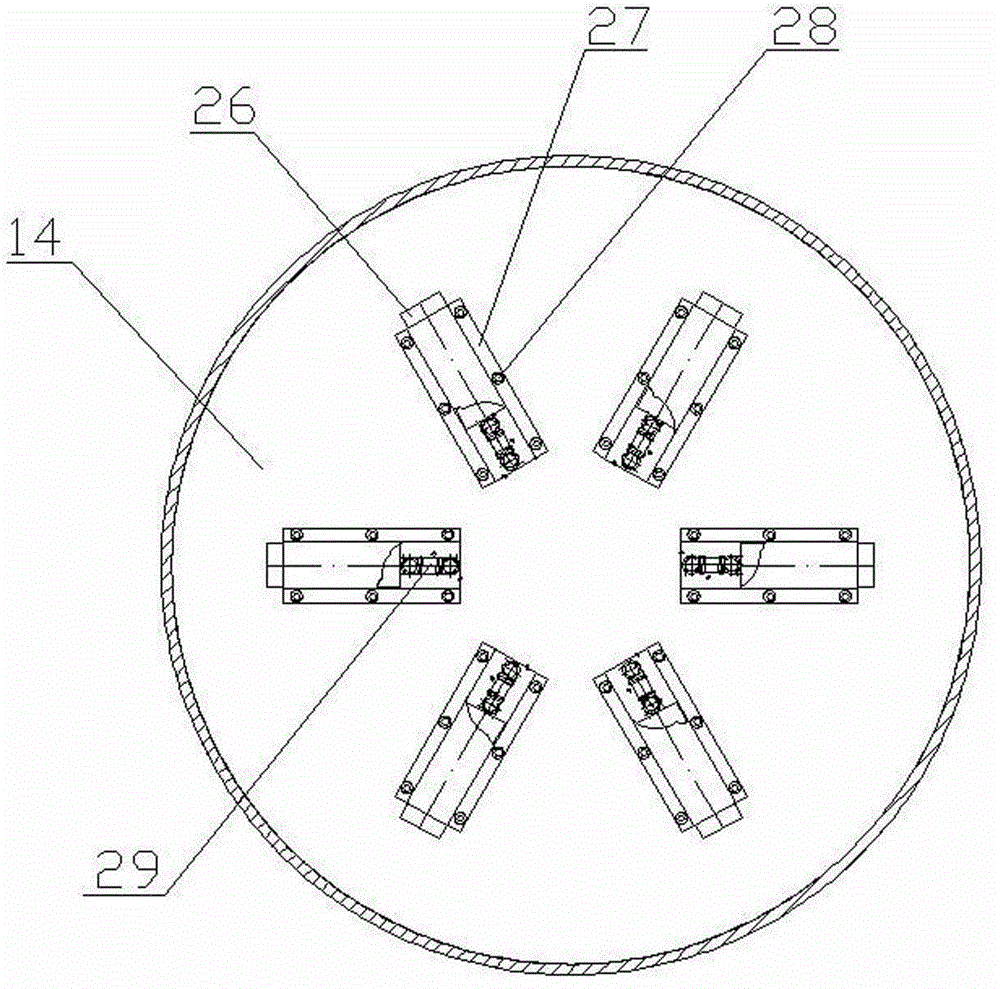

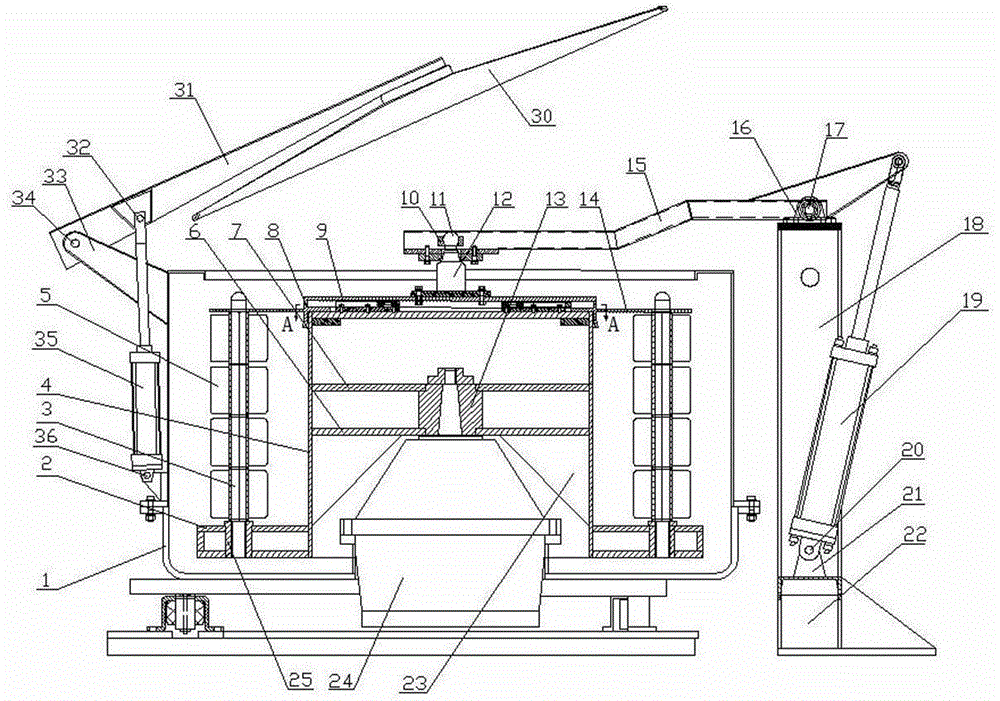

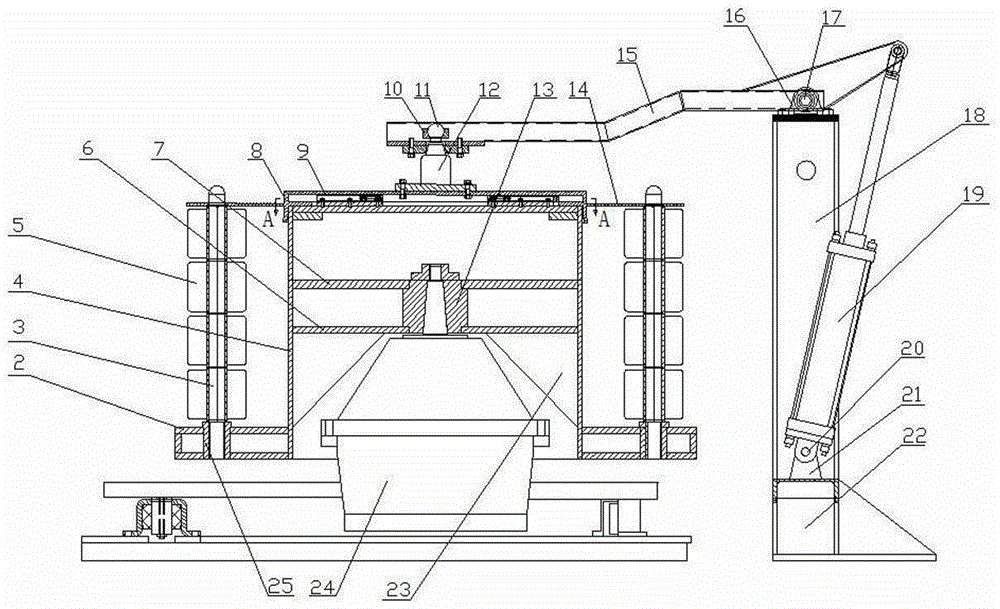

[0019] Such as figure 1 As shown, the bobbin dehydration basket of the present invention comprises a cage body, and the cage body contains a vertical tube 4, and a fixed vertical vertical tube 4 is arranged at about the middle of the height direction of the vertical tube 4 inner cavity. plate, and the periphery of the fixed plate is welded on the inner wall of the vertical cylinder 4. Be processed with central hole on the fixed plate, be provided with 24 below the fixed plate, the output shaft of motor 24 is upward and fix with nut 13 after passing the central hole on the fixed plate. An annular disk 2 is arranged at the lower end of the vertical cylinder 4 , and the inner circumference of the annular disk 2 is welded around the lower end of the vertical cylinder 4 . Vertical rod holes are evenly distributed around the circumference of the annular disk 2, and rod sleeves 25 are installed in the vertical rod holes. A gland 14 is arranged on the upper end of the vertical tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com