Production method of moisture-absorbing sweat-releasing breathable elastic knitted fabric

A knitted fabric, moisture absorption and perspiration technology, applied in the field of textile fabrics, can solve the problems of inability to absorb moisture, perspiration, breathability and high elasticity, not suitable for making clothes, poor moisture absorption of fabrics, etc., to speed up the alkali reduction speed, Good ventilation function, increase the effect of moisture absorption function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

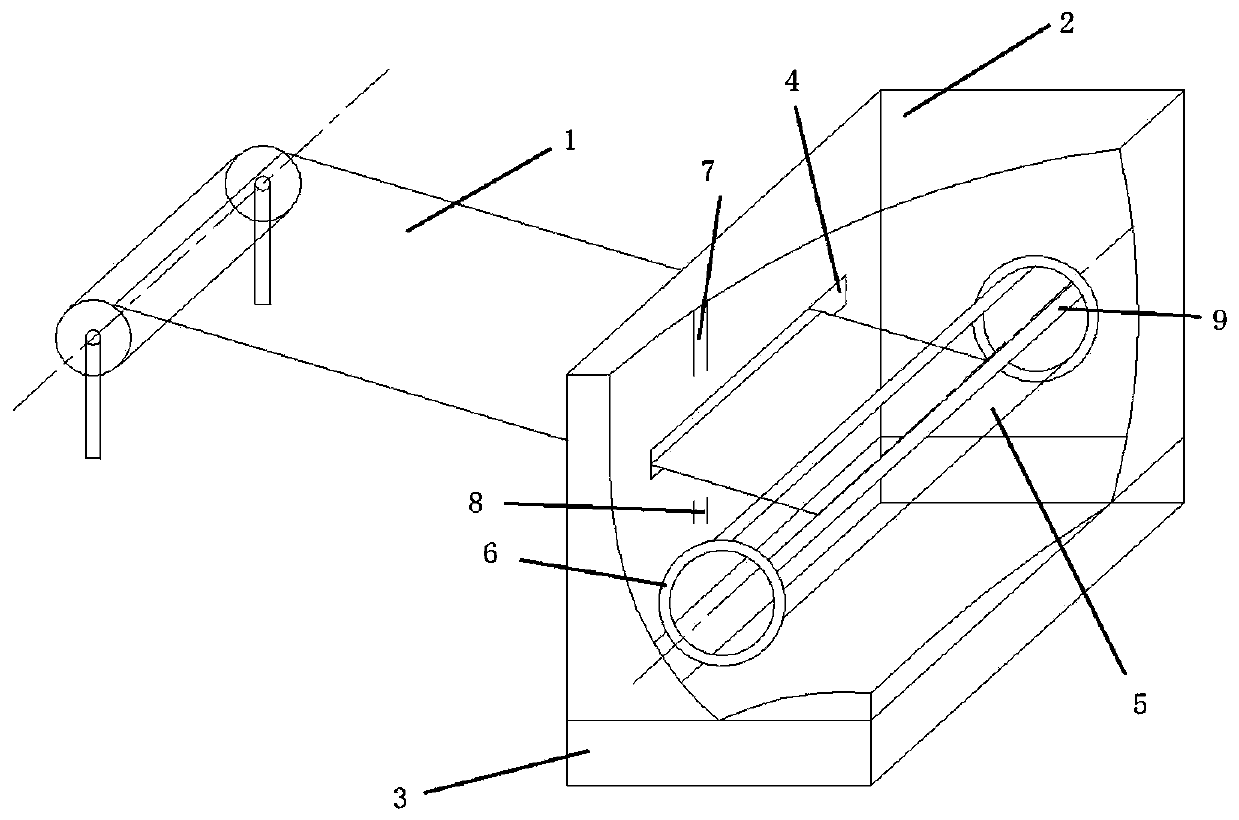

Image

Examples

Embodiment 1

[0046] A method for producing a moisture-absorbing, perspiration-wicking, air-permeable elastic knitted fabric, comprising the following steps:.

[0047] A, select cotton fiber, modified flax fiber, wool fiber and polyurethane fiber as raw materials;

[0048] B, the cotton fiber in step A, modified flax fiber, wool fiber and polyurethane fiber are respectively made into corresponding cotton fiber cheese, modified flax fiber cheese, wool fiber cheese and polyurethane Formate fiber cheese;

[0049] C, the cotton fiber cheese, the modified flax fiber cheese, the wool fiber cheese and the polyurethane fiber cheese in the step B are all evenly wound under the tension force of 0.5 cattle, respectively to obtain cotton fiber Yarns, yarns of modified linen fibers, yarns of wool fibers and yarns of polyurethane fibers;

[0050] D, the cotton fiber yarn obtained in step C, the modified flax fiber yarn, the wool fiber yarn and the polyurethane fiber yarn are brought together under the ...

Embodiment 2

[0073] A method for producing a moisture-absorbing, perspiration-wicking, air-permeable elastic knitted fabric, comprising the following steps:.

[0074] A, select cotton fiber, modified flax fiber, wool fiber and polyurethane fiber as raw materials;

[0075] B, the cotton fiber in step A, modified flax fiber, wool fiber and polyurethane fiber are respectively made into corresponding cotton fiber cheese, modified flax fiber cheese, wool fiber cheese and polyurethane Formate fiber cheese;

[0076] C, the cotton fiber cheese, the modified flax fiber cheese, the wool fiber cheese and the polyurethane fiber cheese in the step B are all evenly wound under the tension force of 0.5 cattle, respectively to obtain cotton fiber Yarns, yarns of modified linen fibers, yarns of wool fibers and yarns of polyurethane fibers;

[0077] D, the cotton fiber yarn obtained in step C, the modified flax fiber yarn, the wool fiber yarn and the polyurethane fiber yarn are brought together under the ...

Embodiment 3

[0093] A method for producing a moisture-absorbing, perspiration-wicking, air-permeable elastic knitted fabric, comprising the following steps:.

[0094] A, select cotton fiber, modified flax fiber, wool fiber and polyurethane fiber as raw materials;

[0095] B, the cotton fiber in step A, modified flax fiber, wool fiber and polyurethane fiber are respectively made into corresponding cotton fiber cheese, modified flax fiber cheese, wool fiber cheese and polyurethane Formate fiber cheese;

[0096]C, the cotton fiber cheese, the modified flax fiber cheese, the wool fiber cheese and the polyurethane fiber cheese in the step B are all evenly wound under the tension force of 0.5 cattle, respectively to obtain cotton fiber Yarns, yarns of modified linen fibers, yarns of wool fibers and yarns of polyurethane fibers;

[0097] D, the cotton fiber yarn obtained in step C, the modified flax fiber yarn, the wool fiber yarn and the polyurethane fiber yarn are brought together under the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com