Linen and viscose blended fabric and processing technology thereof

A technology of blended fabrics and processing technology, applied in the field of textile fabrics, can solve the problems of limited development of hemp fiber varieties, poor wrinkle resistance and wear resistance, and itching, etc., achieve bright dyeing color, not easy to fade, and improve poor comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

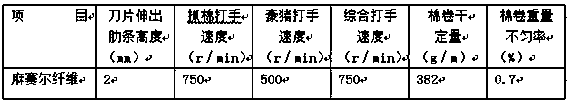

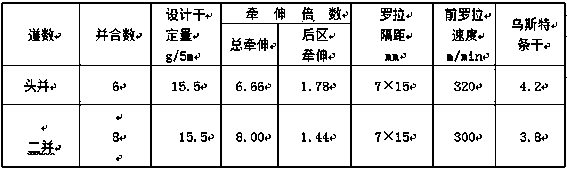

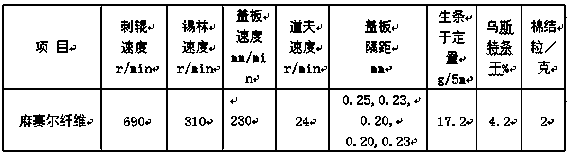

Method used

Image

Examples

Embodiment Construction

[0023] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0024] The linen viscose blended fabric of the present invention is formed by plain weave weaving of warp yarns and weft yarns, the warp yarns are 14.8tex-9.8tex viscose fibers, the weft yarns include weft yarns A and weft yarns B, and the weft yarns A is 14.8tex-9.8tex regenerated hemp The yarn made of cellulose hemp fiber through self-made hemp-like equipment and technology has the quality and style characteristics of hemp yarn; the fiber has a hollow cross-sectional shape similar to hemp fiber, and it absorbs moisture quickly; it retains the excellent antibacterial properties of hemp fiber and is The antibacterial rate of Escherichia coli and Staphylococcus aureus is greater than 90%; weft yarn B is blended with flax fiber and viscose fiber to form a blended yarn of 36tex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com