Improved expansive soil as well as preparation method, construction method and application thereof

A construction method, expansive soil technology, applied in soil protection, infrastructure engineering, roads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

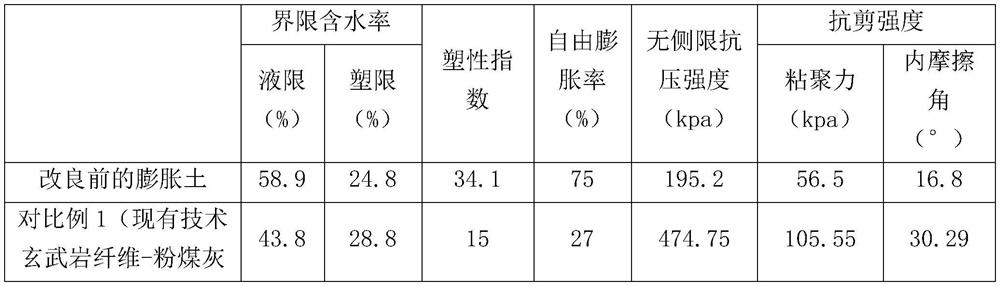

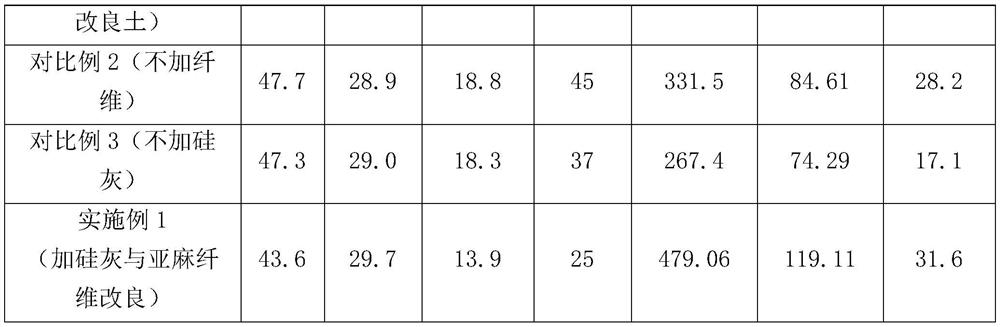

Examples

Embodiment 1

[0027] The improved expansive soil of preparation 2kg, the preparation method of improved expansive soil is as follows:

[0028] (1) take by weighing 1.82kg of expansive soil according to the proportioning ratio of 91%, take by weighing silica fume 0.16kg according to the proportioning ratio of 8%, take by weighing 5 to 20 microns in diameter according to the proportioning proportion of 1%. 20g of flax fiber with a length of 5-6 cm;

[0029] (2) After the expansive soil and silica fume are evenly mixed, according to the "Highway Soil Test Regulations" JTG E40-2007 medium-heavy compaction test, the optimal water content is 25.1%, that is, add 0.502kg of water and stir evenly;

[0030] (3) adding mass percentage is that flax fiber is mixed in expansive soil in step, makes it evenly mix;

[0031] (4) After 2-3 days of stuffing under natural conditions, the improved expansive soil can be obtained.

[0032] Among them, the analysis results of silica fume are, in terms of the mass...

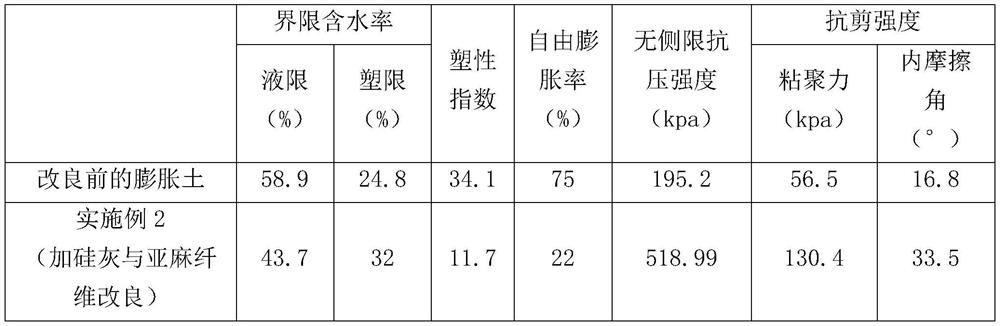

Embodiment 2

[0045] The improved expansive soil of preparation 2kg, the preparation method of improved expansive soil is as follows:

[0046] (1) Take by weighing 1.79kg of expansive soil according to the proportioning ratio of 89.5%, take by weighing 0.18kg of silica fume according to the proportioning ratio of 9%, and weigh 5 to 20 microns in diameter according to the proportioning proportion of 1.5%. 30g of flax fiber with a length of 7-8 cm;

[0047] (2) After the expansive soil and silica fume are mixed evenly, according to the "Highway Geotechnical Test Regulations" JTG E40-2007 medium and heavy compaction test, the optimal water content is 26%, that is, add 0.52kg of water and stir evenly;

[0048] (3) adding mass percentage is that flax fiber is mixed in expansive soil in step, makes it evenly mix;

[0049] (4) After 2-3 days of stuffing under natural conditions, the improved expansive soil can be obtained.

[0050] Among them, the analysis results of silica fume are, in terms of...

Embodiment 3

[0060] The improved expansive soil of preparation 2kg, the preparation method of improved expansive soil is as follows:

[0061] (1) take by weighing 1.76kg of expansive soil according to the proportioning ratio of 88%, take by weighing 0.2kg of silica fume according to the proportioning ratio of 10%, and weigh 5-20 microns in diameter according to the proportioning proportion of 1%. 40g of flax fiber with a length of 9-10 cm;

[0062] (2) After the expansive soil and silica fume are evenly mixed, according to the "Highway Soil Test Regulations" JTG E40-2007 medium-heavy compaction test, the optimal water content is 26.5%, that is, add 0.53kg of water and stir evenly;

[0063] (3) adding mass percentage is that flax fiber is mixed in expansive soil in step, makes it evenly mix;

[0064] (4) After 2-3 days of stuffing under natural conditions, the improved expansive soil can be obtained.

[0065] Among them, the analysis results of silica fume are, in terms of the mass percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com