Super-repellent cement rock modifier and its preparation method and mudstone improvement method

A technology of cement rock and modifier, applied in the direction of coating, etc., can solve the problems of slow ion exchange rate, long time, poor anti-seepage effect and durability, and achieve improved improvement effect, good elasticity and high wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

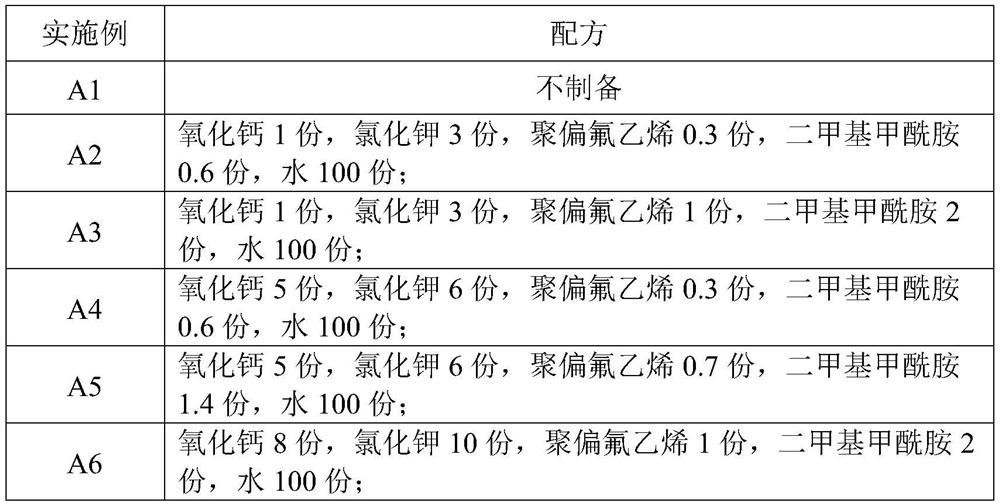

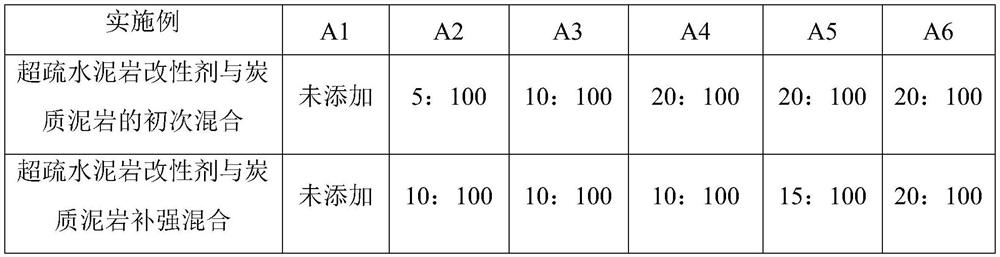

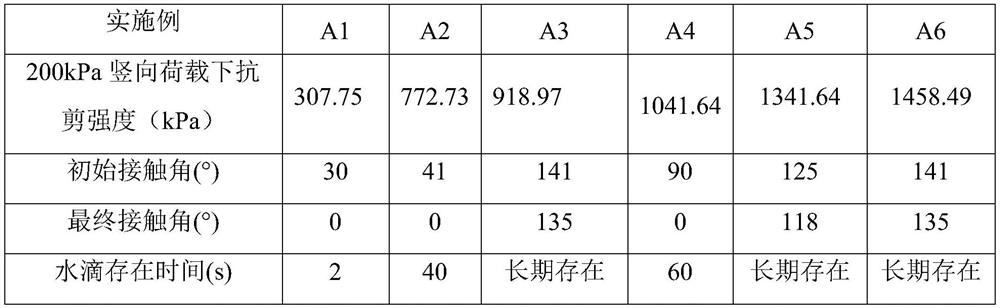

Examples

Embodiment 1

[0028] The preparation method of super-repellent cement rock modifier, concretely carry out according to the following steps:

[0029] Step S1, according to the following parts by mass: 1 part of calcium oxide, 10 parts of potassium chloride, 0.3 part of polyvinylidene fluoride, 0.6 part of dimethylformamide or N-methylpyrrolidone, and weigh the raw materials;

[0030] Step S2, at 20°C, mix the weighed polyvinylidene fluoride (PVDF) with dimethylformamide (DMF), or mix the weighed polyvinylidene fluoride (PVDF) with N-methylpyrrolidone (NMP ) were mixed and stirred for 45 minutes until the mixture became a translucent solution, wherein the mass ratio of polyvinylidene fluoride to dimethylformamide was 1:2;

[0031] Step S3, dissolving the weighed powdered calcium oxide in water and stirring for 45 minutes to obtain a calcium hydroxide solution with a mass concentration of 8%; dissolving the weighed potassium chloride powder in water and stirring evenly to obtain a mass concent...

Embodiment 2

[0034] The preparation method of super-repellent cement rock modifier, concretely carry out according to the following steps:

[0035] Step S1, according to the following parts by mass: 8 parts of calcium oxide, 3 parts of potassium chloride, 1 part of polyvinylidene fluoride, 2 parts of dimethylformamide or N-methylpyrrolidone, and weigh the raw materials;

[0036] Step S2, at 30°C, mix the weighed polyvinylidene fluoride (PVDF) with dimethylformamide (DMF), or mix the weighed polyvinylidene fluoride (PVDF) with N-methylpyrrolidone (NMP ) were mixed and stirred for 40 minutes until the mixture became a translucent solution, wherein the mass ratio of polyvinylidene fluoride to dimethylformamide was 1:2;

[0037]Step S3, dissolve the weighed powdered calcium oxide in water and stir for 35 minutes to obtain a calcium hydroxide solution with a mass concentration of 5%; dissolve the weighed potassium chloride powder in water and stir evenly to obtain a mass concentration of 5% po...

Embodiment 3

[0040] The preparation method of super-repellent cement rock modifier, concretely carry out according to the following steps:

[0041] Step S1, according to the following mass parts: 5 parts of calcium oxide, 6 parts of potassium chloride, 0.7 parts of polyvinylidene fluoride, 1.4 parts of dimethylformamide or N-methylpyrrolidone, and weigh the raw materials;

[0042] Step S2, at 45°C, mix the weighed polyvinylidene fluoride (PVDF) with dimethylformamide (DMF), or mix the weighed polyvinylidene fluoride (PVDF) with N-methylpyrrolidone (NMP ) and stir for 30 minutes until the mixture becomes a translucent solution, wherein the mass ratio of polyvinylidene fluoride to dimethylformamide is 1:2;

[0043] Step S3, dissolving the weighed powdered calcium oxide in water and stirring for 30 minutes to obtain a calcium hydroxide solution with a mass concentration of 1%; dissolving the weighed potassium chloride powder in water and stirring evenly to obtain a mass concentration of 1% p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com