A kind of straw fiber silk reinforced cement improving loose fill foundation and its construction method

A technology of straw fiber silk and construction method, which is applied in infrastructure engineering, soil protection, sustainable waste treatment, etc., and can solve problems such as unknown ratio of straw fiber to soil, little increase in strength, poor water temperature of fiber soil, etc. To reduce the degree of soil sandification and environmental pollution, the construction process is simple and reliable, and the effect of preventing lateral deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

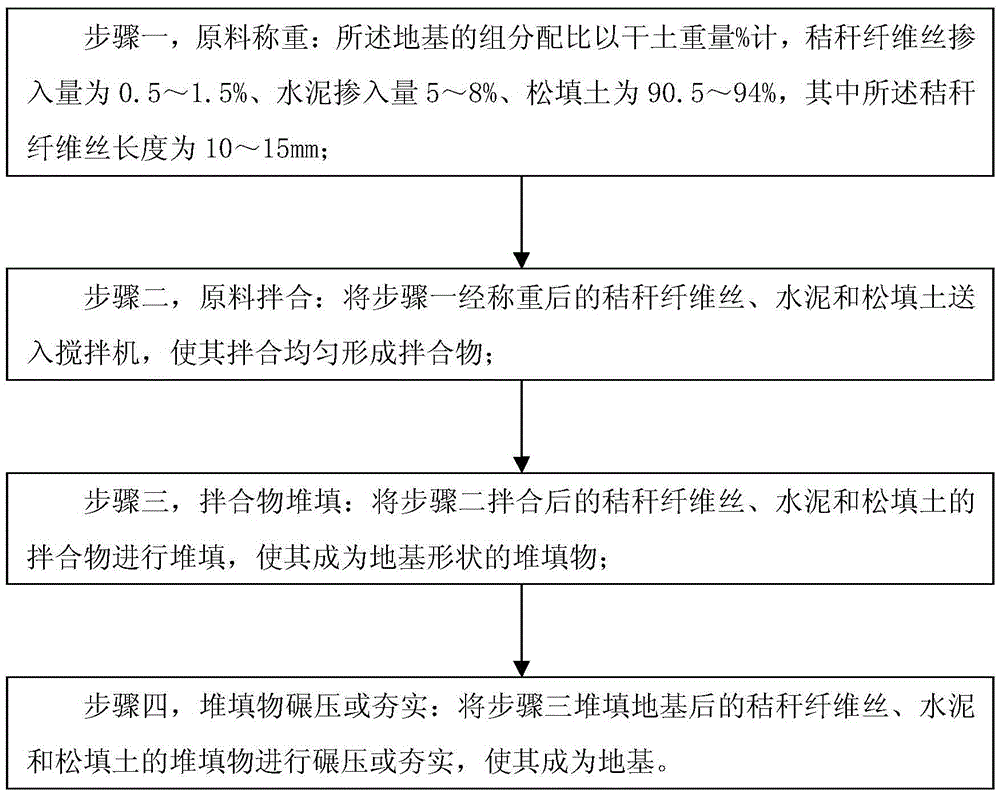

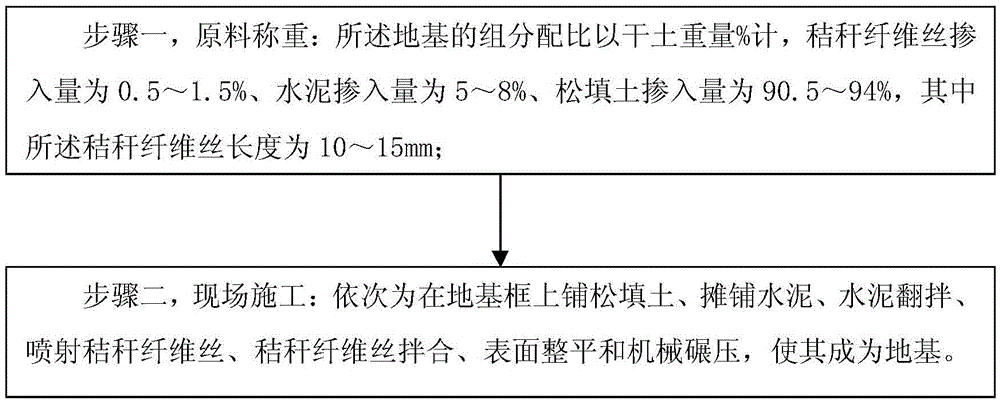

[0021] The specific implementation of the utility model will be further described in detail below in conjunction with the accompanying drawings and examples.

[0022] The present invention proposes a straw fiber silk reinforced cement improved loose fill soil foundation, the component distribution ratio of the foundation is calculated by weight % of dry soil, which specifically includes: the mixing amount of straw fiber silk is 0.5-1.5%, the mixing amount of cement 5-8%, the mixing amount of loose fill soil is 90.5-94%, wherein the length of the straw fiber filaments is 10-15mm.

[0023] An embodiment of the typical component distribution ratio of a kind of straw fiber silk reinforced cement improved loose fill soil foundation proposed by the present invention, in terms of dry soil weight %:

[0024] 1. The mixing amount of straw fiber is 0.5%, the mixing amount of cement is 5%, and the mixing amount of loose fill soil is 94.5%, wherein the length of the straw fiber is 10mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com