Biomass felt, preparation method thereof and application in grassland recovery

A technology of biomass and fiber, applied in botany equipment and methods, applications, lawn growth, etc., can solve the problems of low survival rate of supplementary species, pollute the environment, and unsatisfactory comprehensive treatment effects, so as to save capital investment and promote Plant growth, money saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

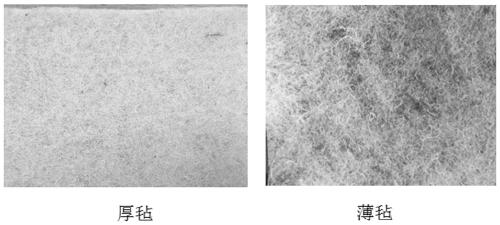

[0037] The preparation of embodiment 1 biomass felt

[0038] (a) 70 parts by weight of wool fiber, 20 parts by weight of flax fiber, and 10 parts by weight of polylactic acid fiber are placed in water, and the fiber raw material is opened into a single fiber state in water, and the stirring is started to fully mix the fiber raw material Evenly, get the fiber suspension slurry, then send the fiber suspension slurry to the non-woven machine;

[0039] (b) Adjust the needling speed of the non-woven machine to 800 times / min, and the needling depth to 5 mm, and use the needling forming non-woven technology to pierce the fiber bundles into the fiber web, so that the fibers in the fiber web are entangled with each other, thereby obtaining a shape Biomass felt material;

[0040] (c) Send the biomass felt material in step (b) into a roller dryer for drying, and finally obtain a finished biomass felt product with a thickness of 3mm, a tensile force of 10N / 5cm, a light transmittance of 6...

Embodiment 2

[0054] Test location: severely degraded saline-alkali grassland in Chabei management area (vegetation coverage is less than 10%);

[0055] Biomass felt selection: thick felt with a width of 1 meter prepared in Example 1;

[0056] Supplementary pasture: choose drought-tolerant and saline-alkali-tolerant Elymus and wild barley;

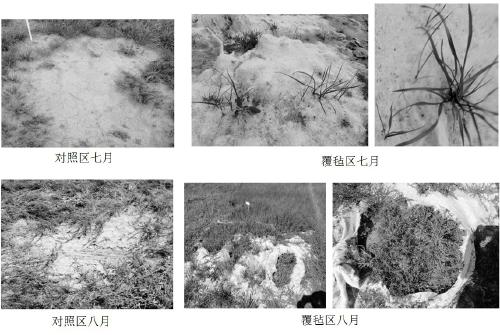

[0057] The experiment adopts randomized block design, each treatment is repeated 4 times, the control group is not covered, other conditions and operations are the same as the test group, the results are shown in Table 4 and figure 2 shown.

[0058] Table 4:

[0059] deal with Grass emergence rate (%) Vegetation height (cm) Coverage(%) control 4.6±0.55b 8.6±1.06b 5.6±0.65b Biomass felt 65.8±2.72a 25.6±1.26a 25.6±1.20ba

[0060] It can be seen from Table 4 that the coverage of biomass felt significantly improved the forage emergence rate, height and vegetation coverage of the experimental plot. The forage emergenc...

Embodiment 3

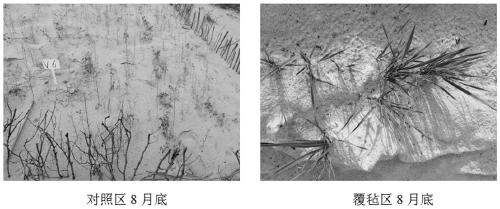

[0062] Test site: Deserted grassland in the background of Yuanshan sub-project area, Yudaokou Township, Weichang County, Chengde City, Hebei Province (vegetation coverage <5%);

[0063] Supplementary sowing grass: choose suitable and drought-resistant Elymus and wheatgrass among the surrounding vegetation;

[0064] Biomass felt selection: thick felt with a width of 1 meter prepared in Example 1;

[0065] 60 test plots covered with biomass felt and supplementary seeding were arranged, each plot was 16 square meters. The difference between the method and the prior art is that the combination of covering the fenced desertified grassland with biomass felt and supplementing grass seeds. The control group was not covered, and other conditions and operations were the same as those of the test group. The results are shown in Table 5 and image 3 shown.

[0066] Table 5: First Year

[0067] deal with Germination rate Survival number (strain / m2) Number of tillers (pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com