Rapid qualitative filter paper and preparation method thereof

A qualitative filter paper and fast technology, applied in pulp beating/refining method, filter paper, separation method, etc., can solve the problems of inability to meet the requirements of filter paper, poor strength and toughness of filter paper, etc., and achieve easy use and environmental protection, not easy to break, good toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

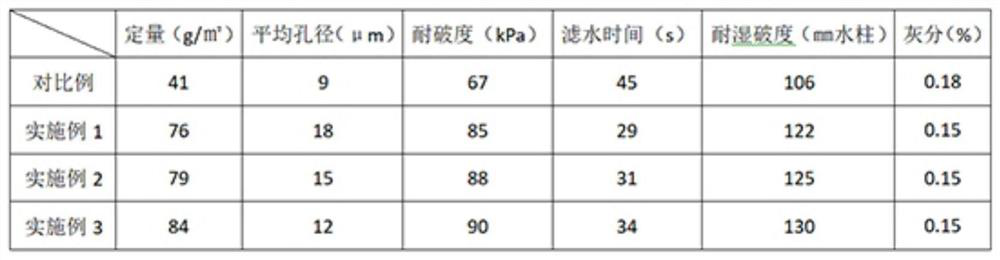

Embodiment 1

[0025] A high-performance rapid qualitative filter paper, calculated in parts by weight: 40 parts of mixed pulp of alkali-treated cotton linter pulp and alkali-treated cotton long-lint pulp, 40 parts of coniferous wood pulp, 20 parts of mixed plant fiber, 2 parts of viscose Fiber, 2 parts of water-soluble phenolic resin, 2 parts of polypropylene fiber, wherein the mixed plant fiber includes 4 parts of bamboo fiber, 4 parts of psyllium seed fiber, 4 parts of straw fiber, 4 parts of flax fiber, and 4 parts of asparagus pulp.

[0026] Follow the steps below to prepare targeted rapid qualitative filter paper:

[0027] a) Thaw out the mixed pulp of alkali-treated cotton short-fluff pulp and alkali-treated cotton long-fluff pulp, water-soluble phenolic resin, and viscose fiber with a fiber deflagging machine, and add 1 part of vinyl bis stearamide and 1 part of polyamide at the same time Polyepichlorohydrin resin, and then through double-disc refiner on-line grinding to obtain pulp ...

Embodiment 2

[0032] A high-performance rapid qualitative filter paper, calculated in parts by weight: 70 parts of mixed pulp of alkali-treated cotton linter pulp and alkali-treated cotton linter pulp, 70 parts of coniferous wood pulp, 35 parts of mixed plant fiber, 4 parts of viscose Fiber, 3 parts of water-soluble phenolic resin, 3 parts of polypropylene fiber, wherein the mixed plant fiber includes 7 parts of bamboo fiber, 7 parts of psyllium seed fiber, 7 parts of straw fiber, 7 parts of flax fiber, and 7 parts of asparagus pulp.

[0033] Follow the steps below to prepare targeted rapid qualitative filter paper:

[0034] a) The mixed pulp of alkali-treated cotton short-fluff pulp and alkali-treated cotton long-fluff pulp, water-soluble phenolic resin, and viscose fiber are decomposed with a fiber deflagging machine, and 1.3 parts of vinyl bis stearamide and 1.3 parts of polyamide are added at the same time Polyepichlorohydrin resin, and then through double-disk refiner on-line grinding ...

Embodiment 3

[0039] A high-performance rapid qualitative filter paper, calculated in parts by weight: 100 parts of mixed pulp of alkali-treated cotton linter pulp and alkali-treated cotton long-fluff pulp, 100 parts of coniferous wood pulp, 50 parts of mixed plant fiber, 5 parts of viscose fiber, 5 parts of water-soluble phenolic resin, and 5 parts of polypropylene fiber, wherein the mixed plant fiber includes 10 parts of bamboo fiber, 10 parts of psyllium seed fiber, 10 parts of straw fiber, 10 parts of flax fiber, and 10 parts of asparagus pulp.

[0040] Follow the steps below to prepare targeted rapid qualitative filter paper:

[0041] a) Decompose the mixed pulp of alkali-treated cotton short-fluff pulp and alkali-treated cotton long-fluff pulp, water-soluble phenolic resin, and viscose fiber with a fiber deflagging machine, and add 1.5 parts of vinyl bis stearamide and 1.5 parts of polyamide at the same time Polyepichlorohydrin resin, and then through double-disc refiner on-line grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com