Composite spinning process of antibacterial aromatic yarn

A composite spinning and fragrant technology, which is applied in the field of composite spinning of antibacterial aromatic yarns, can solve the problems of insufficient antibacterial performance and poor durability, and achieves excellent moisture absorption and breathability, good spinnability and high viscosity. Solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

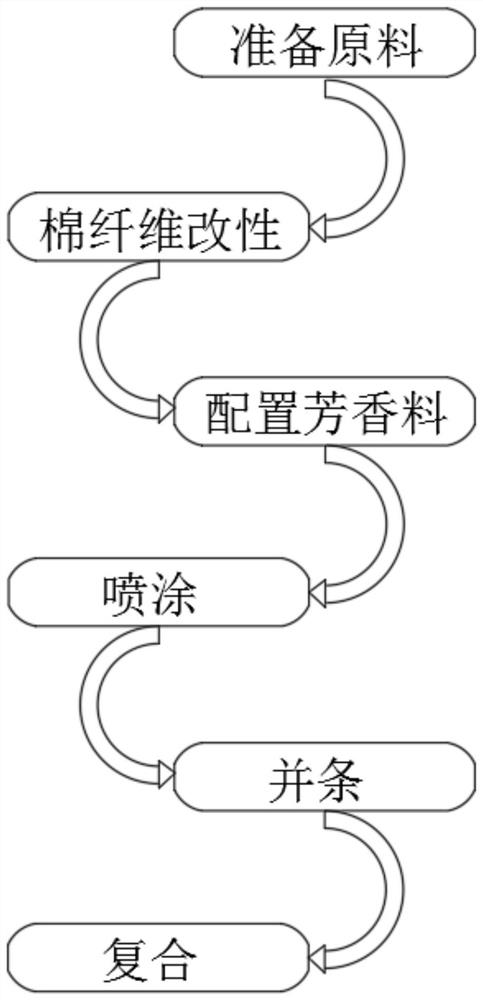

[0030] refer to figure 1 , a composite spinning process of antibacterial aromatic yarn, comprising the following steps:

[0031] S1: prepare raw materials, 30 parts of cotton fiber, 25 parts of flax fiber, 8 parts of copper fiber;

[0032] S2: Cotton fiber modification, polyallylamine, NaOH and reaction medium are uniformly mixed to form a reaction solution, cotton fiber is added to the reaction solution, and the cotton fiber is washed to neutral after treatment to obtain cationic cotton fiber. The cotton fiber obtained after activating has a high degree of cationicity, which greatly improves the adsorption performance of cotton fiber to fragrances;

[0033] S3: Prepare the fragrance, put the fragrance, diatomaceous earth, and activated carbon powder into the mixing tank for mixing to obtain the mixed solution A, and store the fragrance by using porous materials such as diatomaceous earth and activated carbon powder for long-lasting fragrance;

[0034] S4: Spraying, spray gl...

Embodiment 2

[0040] refer to figure 1 , a composite spinning process of antibacterial aromatic yarn, comprising the following steps:

[0041] S1: prepare raw materials, 35 parts of cotton fiber, 28 parts of flax fiber, 8 parts of copper fiber;

[0042] S2: Cotton fiber modification, polyallylamine, NaOH and reaction medium are uniformly mixed to form a reaction solution, cotton fiber is added to the reaction solution, and the cotton fiber is washed to neutral after treatment to obtain cationic cotton fiber. The cotton fiber obtained after activating has a high degree of cationicity, which greatly improves the adsorption performance of cotton fiber to fragrances;

[0043] S3: Prepare the fragrance, put the fragrance, diatomaceous earth, and activated carbon powder into the mixing tank for mixing to obtain the mixed solution A, and store the fragrance by using porous materials such as diatomaceous earth and activated carbon powder for long-lasting fragrance;

[0044] S4: Spraying, spray gl...

Embodiment 3

[0050] refer to figure 1 , a composite spinning process of antibacterial aromatic yarn, comprising the following steps:

[0051] S1: prepare raw materials, 30 parts of cotton fiber, 28 parts of flax fiber, 10 parts of copper fiber;

[0052]S2: Cotton fiber modification, polyallylamine, NaOH and reaction medium are uniformly mixed to form a reaction solution, cotton fiber is added to the reaction solution, and the cotton fiber is washed to neutral after treatment to obtain cationic cotton fiber. The cotton fiber obtained after activating has a high degree of cationicity, which greatly improves the adsorption performance of cotton fiber to fragrances;

[0053] S3: Prepare the fragrance, put the fragrance, diatomaceous earth, and activated carbon powder into the mixing tank for mixing to obtain the mixed solution A, and store the fragrance by using porous materials such as diatomaceous earth and activated carbon powder for long-lasting fragrance;

[0054] S4: Spraying, spray gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com