Patents

Literature

34results about How to "Remarkable effect of strengthening and toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and high-tenacity polypropylene composite materials and preparation method thereof

The invention discloses high-strength and high-tenacity polypropylene composite materials. The high-strength and high-tenacity polypropylene composite materials solve the problems that existing polypropylene is poor in tenacity and poor in strength. The high-strength and high-tenacity polypropylene composite materials are formed by the following components, by weight, 35-75% of polypropylene, 10-40% of calcium carbonate, 8-25% of calcium sulfate whisker masterbatch, 0.1-2% of coupling agents, 2-8% of compatilizer, 0.3-4% of lubricating agents and 0.2-0.8% of antioxygen. The invention further provides a preparation method of the high-strength and high-tenacity polypropylene composite materials. According to the preparation method of the high-strength and high-tenacity polypropylene composite materials, through the mode that calcium sulfate whiskers are made into masterbatch, the calcium sulfate whisker masterbatch is added to plastics to carry out co-extrusion mixing with the plastics and the like, thus, compared with powdery whiskers, material preparation can be evener and controllable, the problem that material preparation of the calcium sulfate whiskers is difficult is solved, meanwhile, the calcium sulfate whiskers are made to have better dispersity in plastic substrate, and the surfaces of products are smoother.

Owner:四川万润非金属矿物材料有限公司

Montmorillonite/rare-earth stabilizer for PVC and preparation method thereof

ActiveCN101456972AImprove thermal stabilization efficiencyFast heat conductionOrganificationRare earth

The invention relates to a PVC montmorillonite / rare-earth stabilizing agent and a preparation method thereof, wherein, weight part components of the stabilizing agent comprise 100 of montmorillonite, 1 to 40 of organic rare-earth salts, 200 to 500 of dispersive medium, 1 to 10 of surface modifying agent, and 10 to 50 of auxiliary stabilizing agent. The organic rare-earth salts are prepared by organification of lanthanides inorganic rare-earth salt and long chain fatty acid. The long chain fatty acid is epoxy oleic acid, stearic acid, lauric acid or citric acid, taking up 5 percent to 40 percent of gross mass of the organic rare-earth salt. The long chain fatty acid takes up 20 percent to 40 percent of gross mass of the organic rare-earth salt. The invention overcomes defects of soft quality of traditional stabilizing agent and weak absorption ability of ultraviolet radiation and is provided with fine stripping performance and high reinforcing ability, and can effectively improve anti-attacking performance of PVC compound materials, realizes fine annealing strengthening and strengthening effects of nanometer padding and is provided fine barrier function to ultraviolet irradiation. The invention is suitable to PVC materials requiring high material mechanical strength.

Owner:威海大河新材料科技股份有限公司

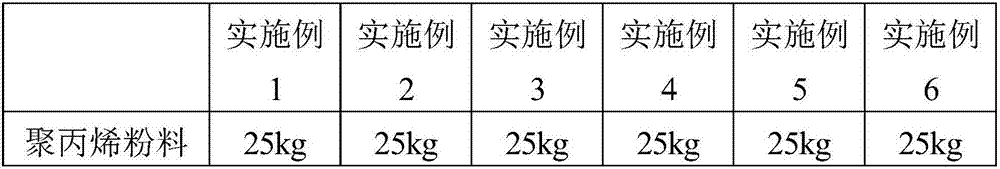

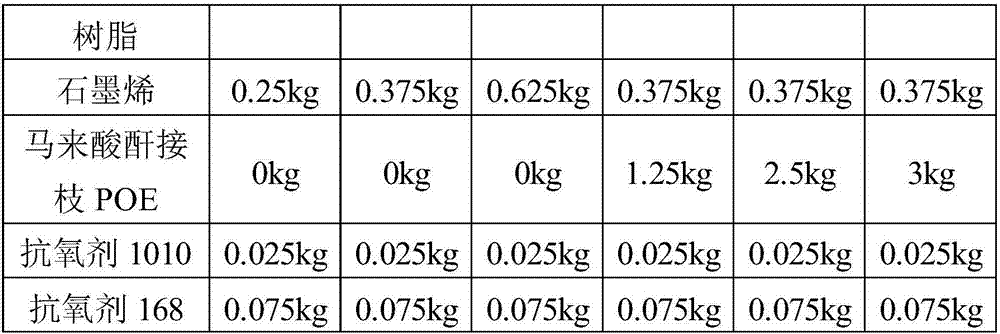

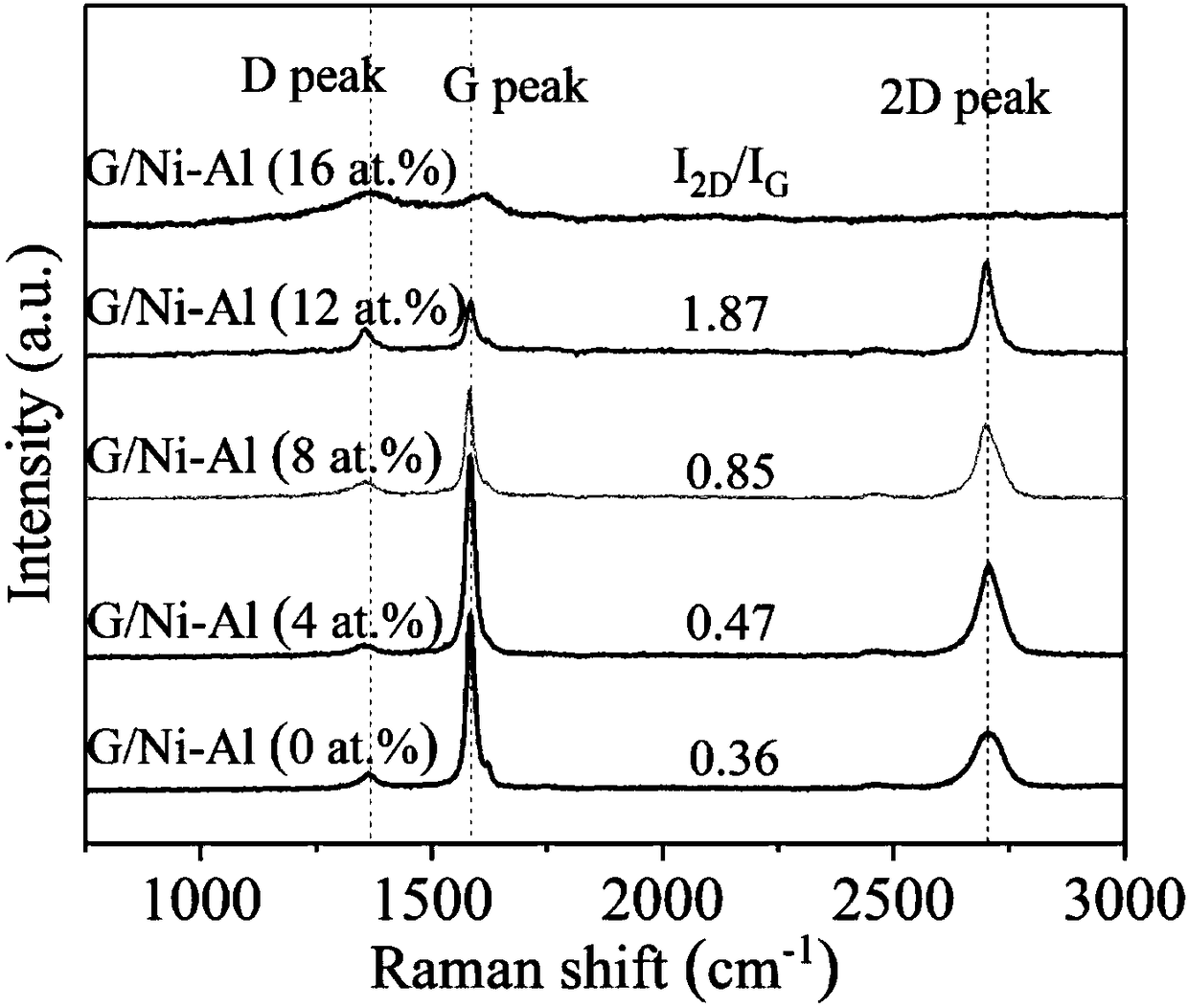

Modified polypropylene material and preparation method thereof

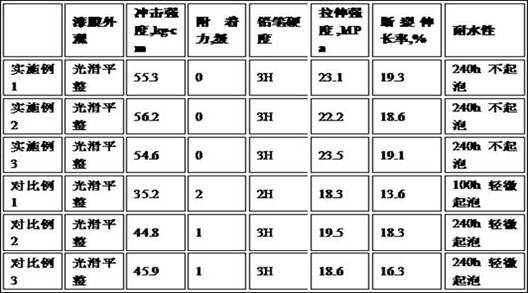

InactiveCN107383615ARemarkable effect of strengthening and tougheningImprove toughnessHeat deflection temperaturePolypropylene

The invention discloses a modified polypropylene material and a preparation method thereof. The modified polypropylene material is composed of 100 parts by weight of polypropylene resin, 0.5 to 5 parts by weight of a modifier, 0 to 15 parts by weight of a compatibilizer and 0.1 to 0.4 parts by weight of a composite antioxidant. The modified polypropylene material has good strengthening and toughening performances, a high thermal decomposition temperature and a high thermal deformation temperature.

Owner:JIANGSU UNIV OF TECH

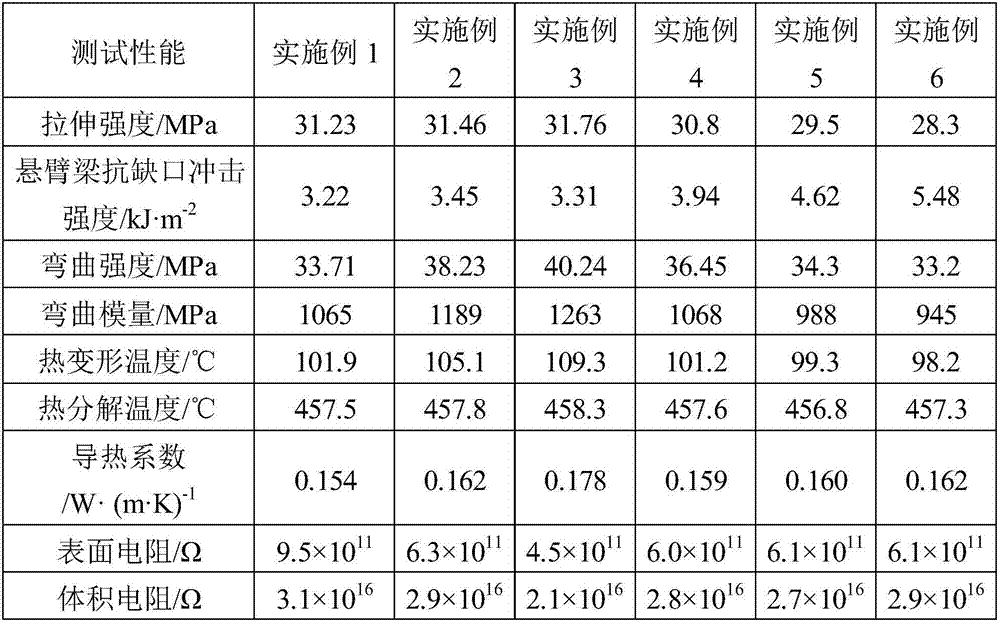

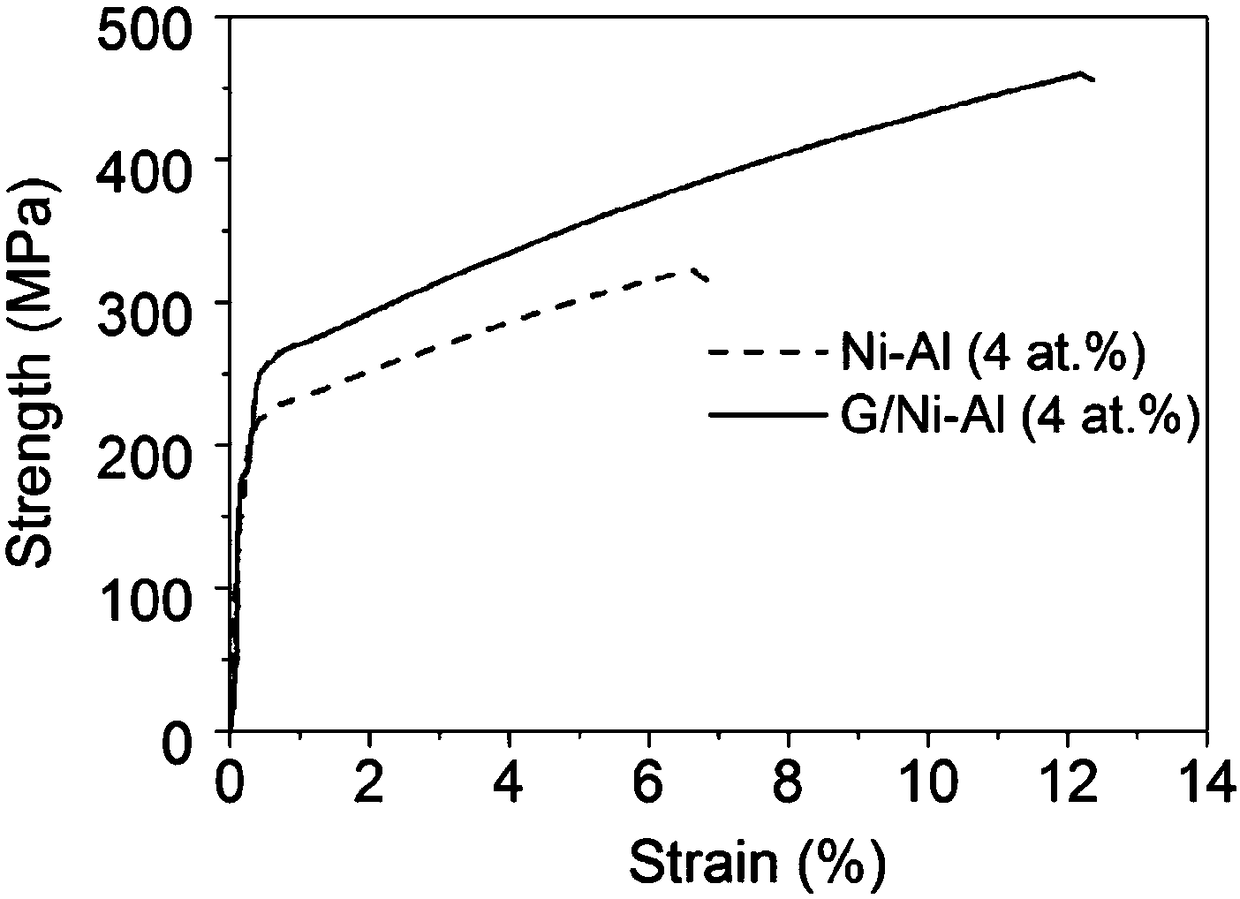

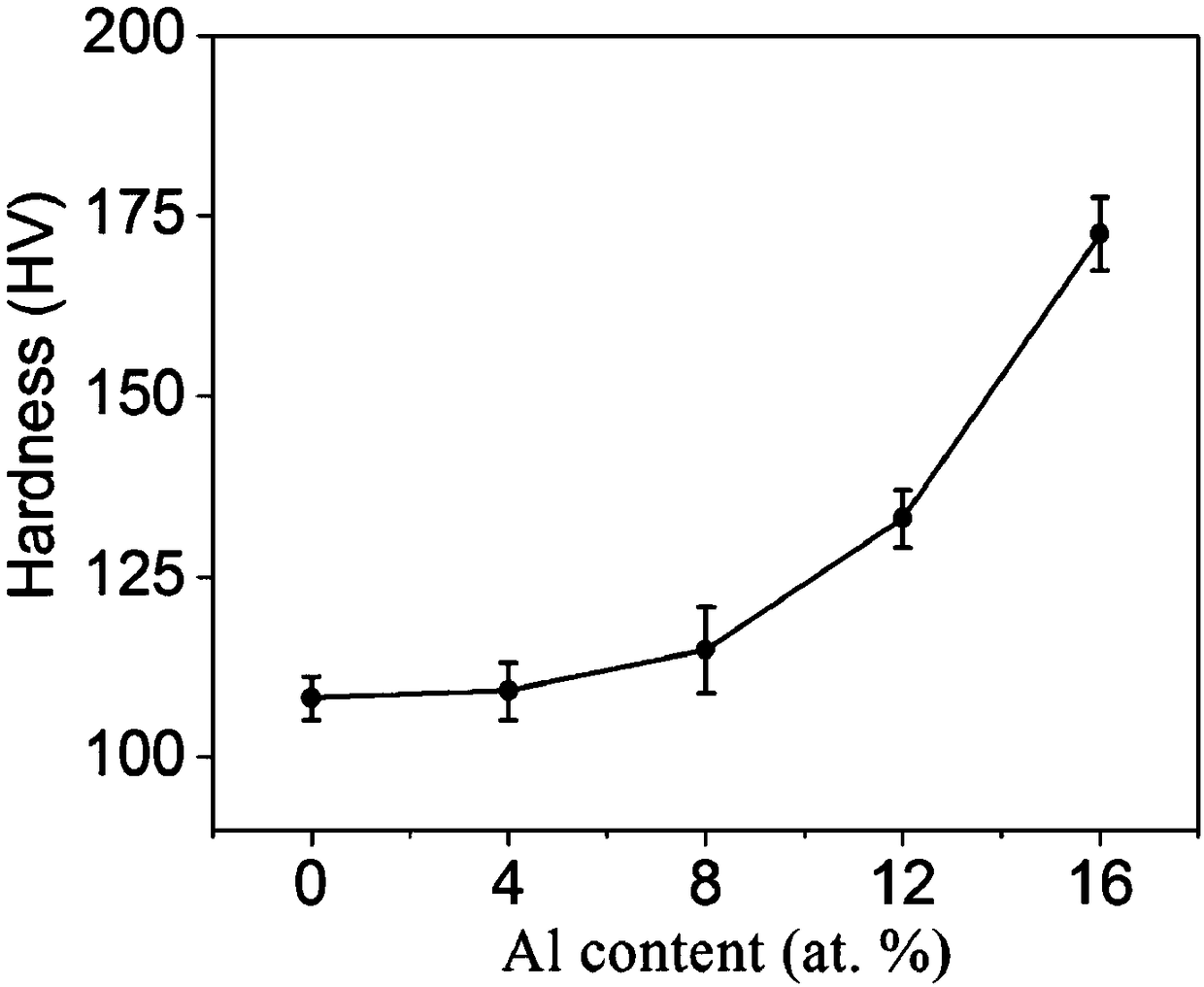

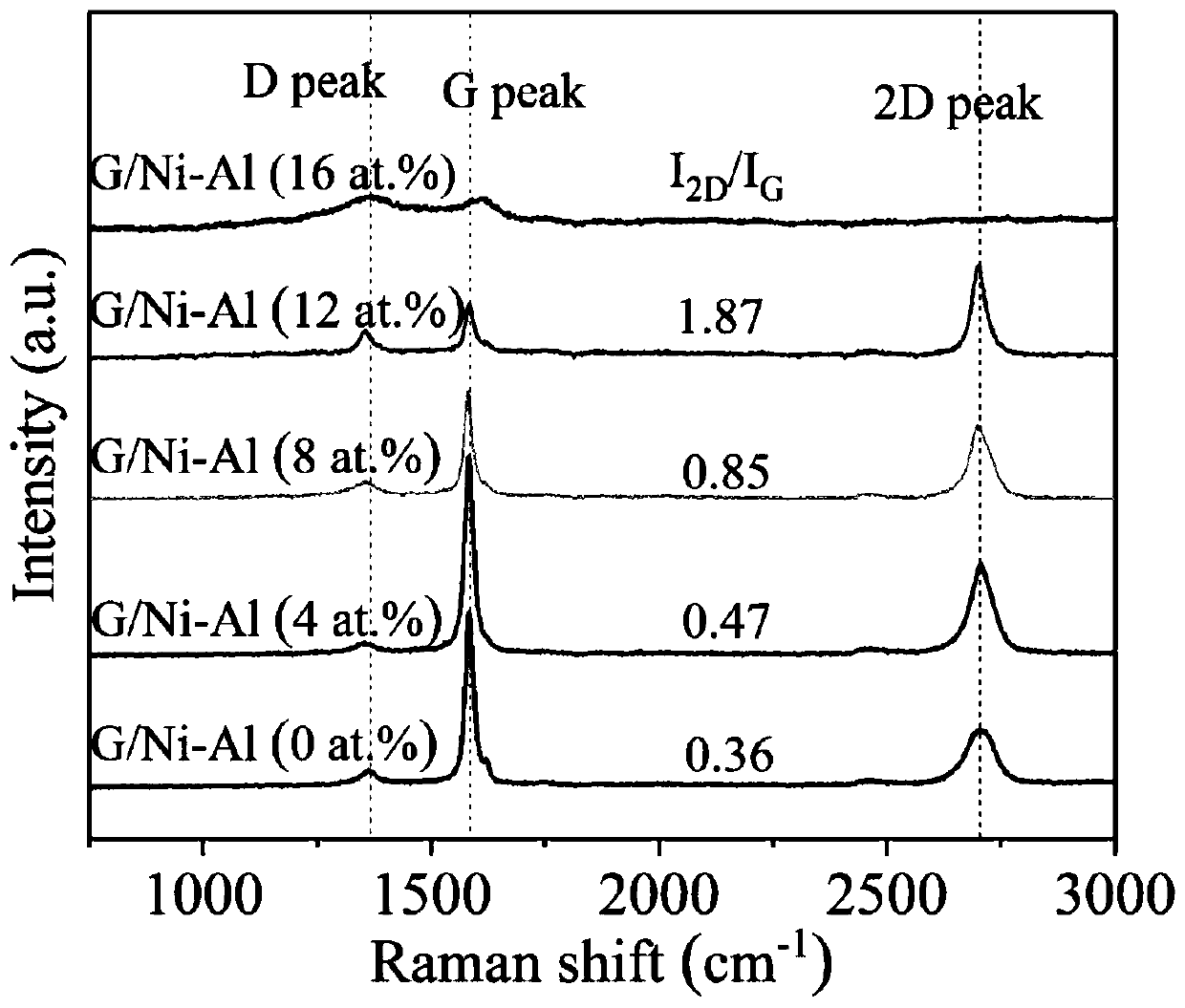

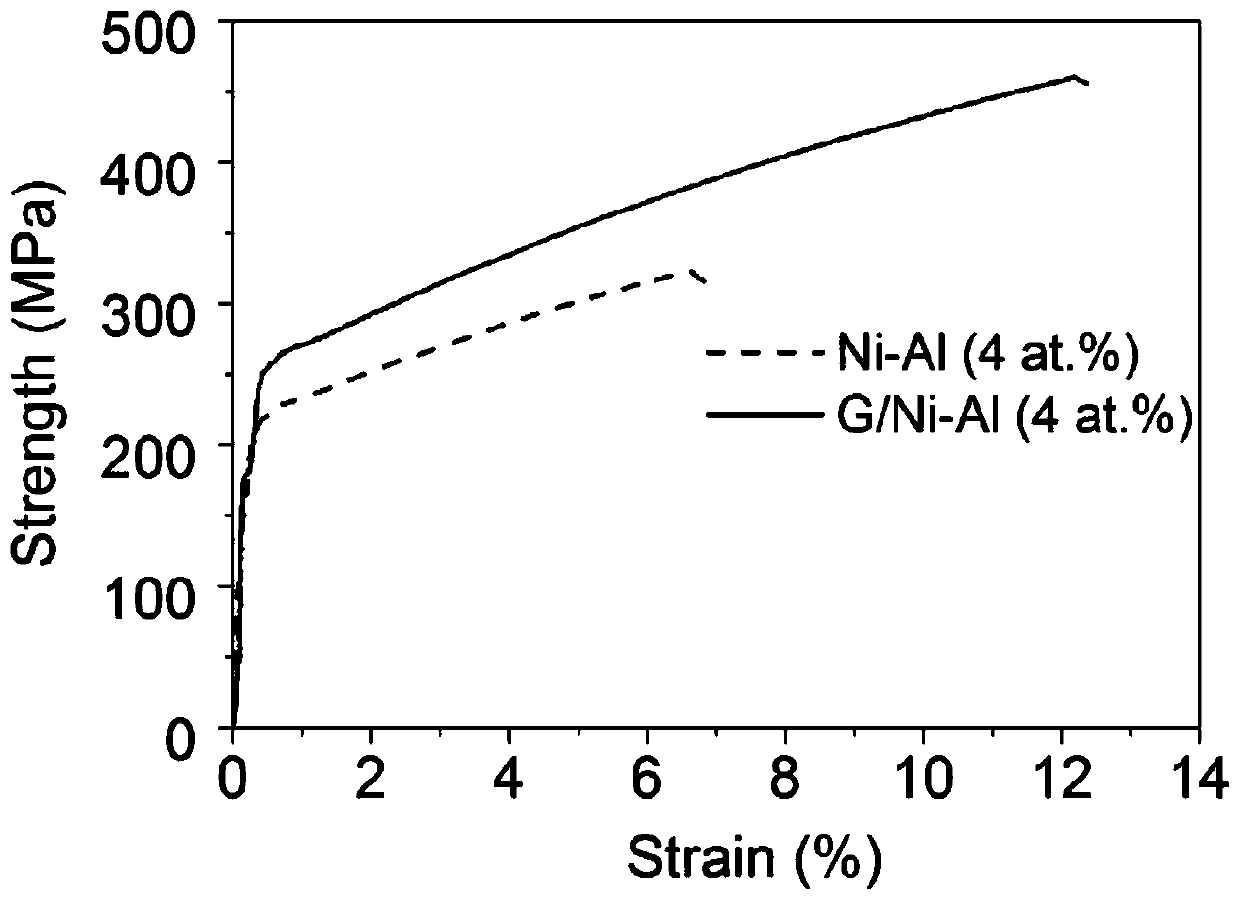

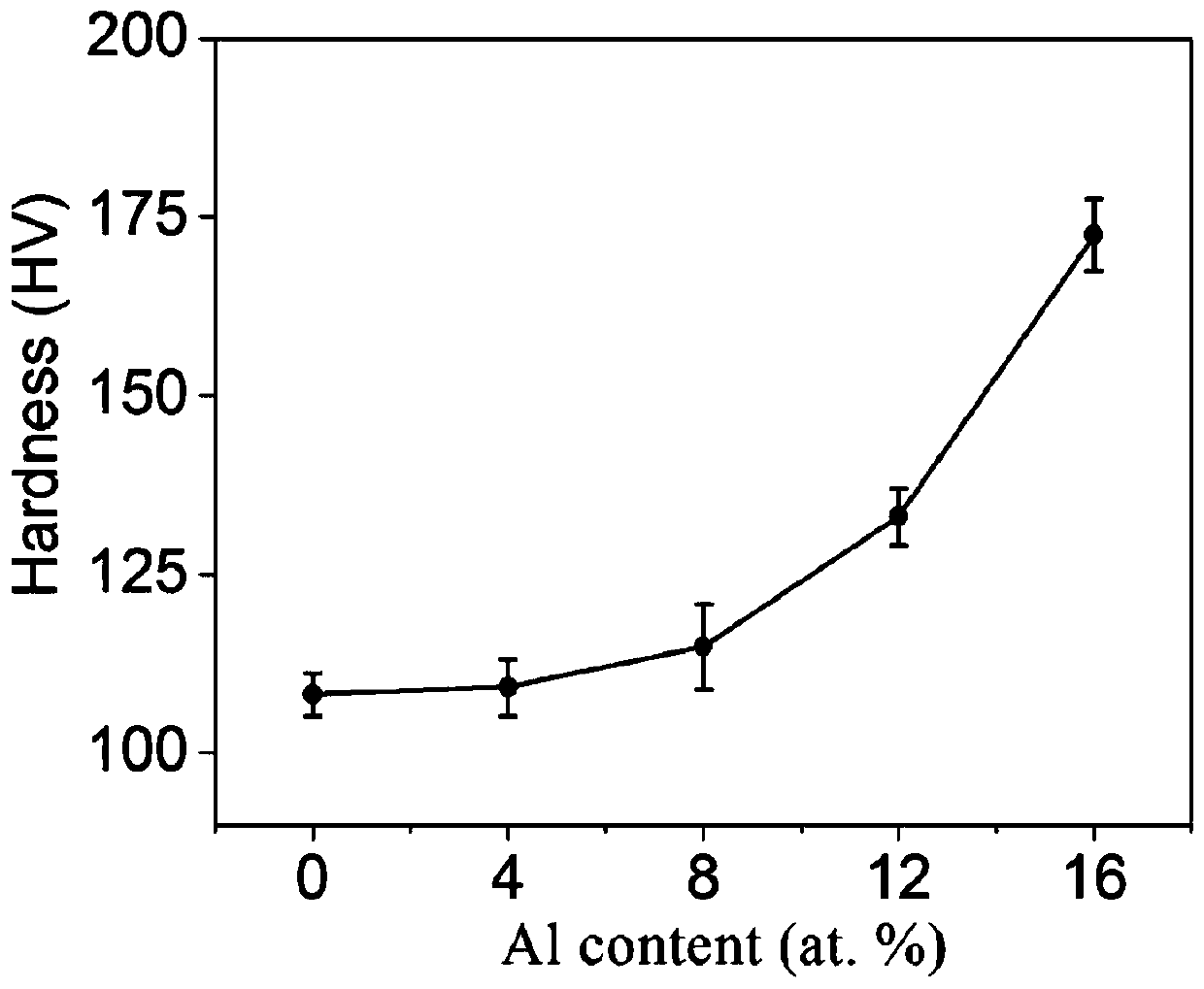

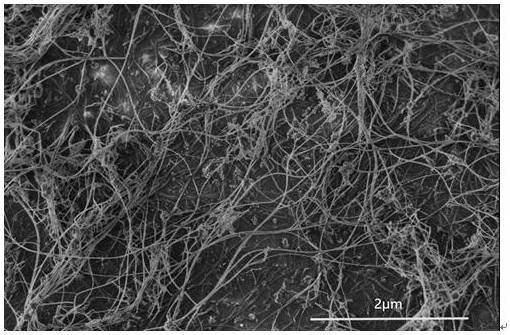

Preparation method of graphene strengthened nickel-aluminum alloy based composite

InactiveCN108531780ASolving Difficult Difficult PuzzlesEasy to controlSolid solutionMetal matrix composite

The invention relates to a preparation method of a graphene strengthened nickel-aluminum alloy based composite and belongs to the technical field of metal based composites. In the method, by taking asolid carbon source as a precursor of graphene, the problem that the graphene is difficult to disperse is solved; by utilizing metal aluminum to regulate the solid solution and precipitation process of carbon atoms in a nickel matrix in the solid solution process in the nickel matrix, growth of the graphene is controlled, the graphene with a controllable layer number is prepared, and the graphene,growing in situ, is good in interface bonding force with a nickel-aluminum alloy matrix to have remarkable strengthening and toughening effects to the nickel-aluminum alloy matrix; and in addition, the growth process of the graphene and the densification sintering process of the nickel-aluminum matrix are performed at one step, the preparation process is simple, is good in controllability and issuitable for mass production.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Polyamide 6 modified material for additive manufacturing, and preparation method thereof

InactiveCN107778846ASimple processGood modification effectAdditive manufacturing apparatusPolyamideGlass fiber

The invention relates to the field of additive manufacturing consumables, and discloses a polyamide 6 modified material for additive manufacturing, and a preparation method thereof. The polyamide 6 modified material comprises, by mass, 62-78% of polyamide 6 (PA6), 8-15% of glass fibers, 8-20% of a toughener, 5-10% of a compatibilizer, 0.3-2% of an antioxidant and 0.2-1% of a fiber glass exposure inhibitor. The preparation method has a simple process, and has the following remarkable modification effects: 1, the glass fibers and the toughener are added, so the mechanical strength and the toughness of the prepared polyamide 6 modified material are obviously improved, and the strengthening and toughening effects are remarkable; 2, the preferable glass fiber exposure inhibitor is added, so thefree fluidity of the material is improved, and the processing performances are improved, thereby the surface glossiness of the material is high; 3, the material has a lower shrinkage rate and a higher thermal deformation temperature than traditional nylon materials; and 4, printing verifies that silks are smoothly produced from nozzles during 3D printing, and the material has the advantages of low warping, high precision and good appearance quality, and is very suitable for producing consumables for FDM additive manufacturing.

Owner:四川鑫达企业集团有限公司

High-impact-toughness foamed aluminum based on A356 aluminum alloy and production process of high-impact-toughness foamed aluminum

The invention relates to a foamed aluminum material, in particular to high-impact-toughness foamed aluminum based on A356 aluminum alloy and a production process of the high-impact-toughness foamed aluminum. The production process comprises the steps that (1) 12-20 parts, by weight, of a foaming agent is ground and screened through a sieve with 100-180 meshes; (2) 100 parts, by weight, of A356 aluminum alloy ingots are crushed, ground into particles and then evenly mixed with 8-15 parts, by weight, of inorganic nano-whiskers and 10-12 parts, by weight, carbon nano-tubes, then a mixture is placed into a smelting furnace and completely molten in an inert gas atmosphere, afterwards, the foaming agent is sucked in to the smelting furnace under negative pressure, and a molten aluminum mixture is obtained after uniform mixing; (3) the molten aluminum mixture obtained in the step (2) is poured into a mold, the mold is then pushed into a foaming furnace, and heat preservation is conducted for1-2h at the temperature of 680-700 DEG C; and (4) the mold enters a cooling system to be cooled, and thus the foamed aluminum is obtained. According to the high-impact-toughness foamed aluminum basedon the A356 aluminum alloy and the production process of the high-impact-toughness foamed aluminum, the mixture of the inorganic nano-whiskers and the carbon nano-tubes is added in the forming processof the foamed aluminum, and thus the impact toughness of the aluminum is remarkably improved.

Owner:JIESHOU JINGHUA TECH INFORMATION CONSULTING SERVICE CO LTD +1

Tube for high-voltage wires

InactiveCN104164020AHigh compressive strengthImprove the anti-leakage effectCross-linkAluminium hydroxide

A disclosed tube for high-voltage wires is prepared from the following raw materials in parts by weight: 25-50 parts of polyvinylchloride resin, 1-3 parts of polytetrafluoroethylene wax, 2-4 parts of N,N-diethylaniline, 3-6 parts of disodium methylenebisnaphthalenesulphonate, 2-5 parts of aluminium hydroxide, 3-7 parts of flint clay powder, 4-8 parts of calcium phosphate, 2-6 parts of polyethylene glycol fatty acid ester, 2-5 parts of cross-linking agent TAC, 4-7 parts of valerian oil, 5-9 parts of poly(brominated styrene), and 4-8 parts of stannic oxide. The provided tube for high-voltage wires is good in anti-creeping property, high in pressure-resistant strength, excellent heat resistance and high impact resistance.

Owner:QINGDAO JISHUNLONG TRADING

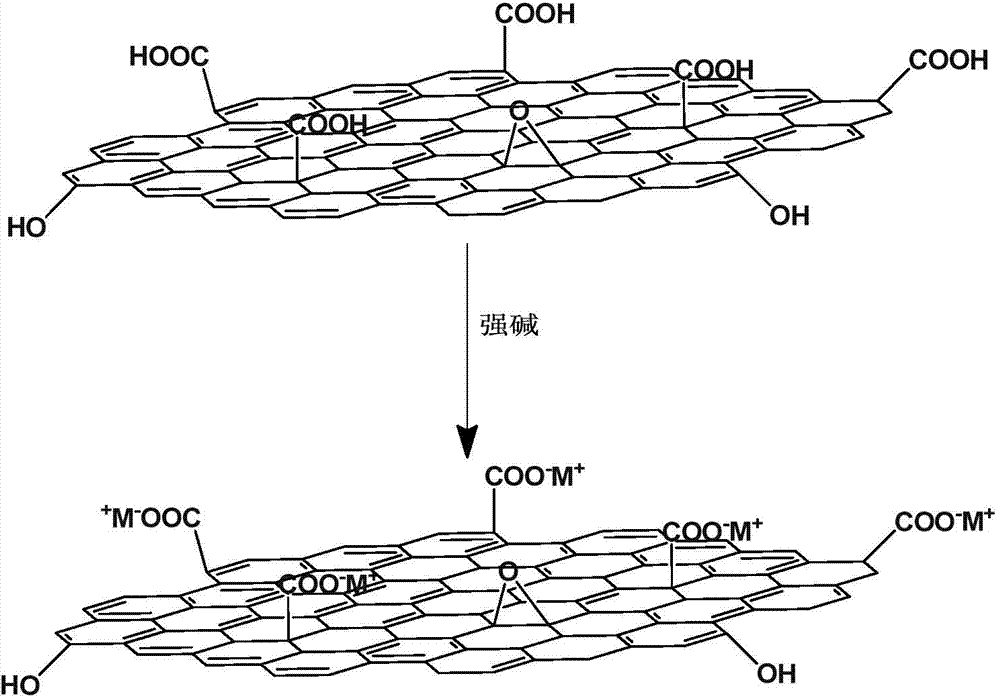

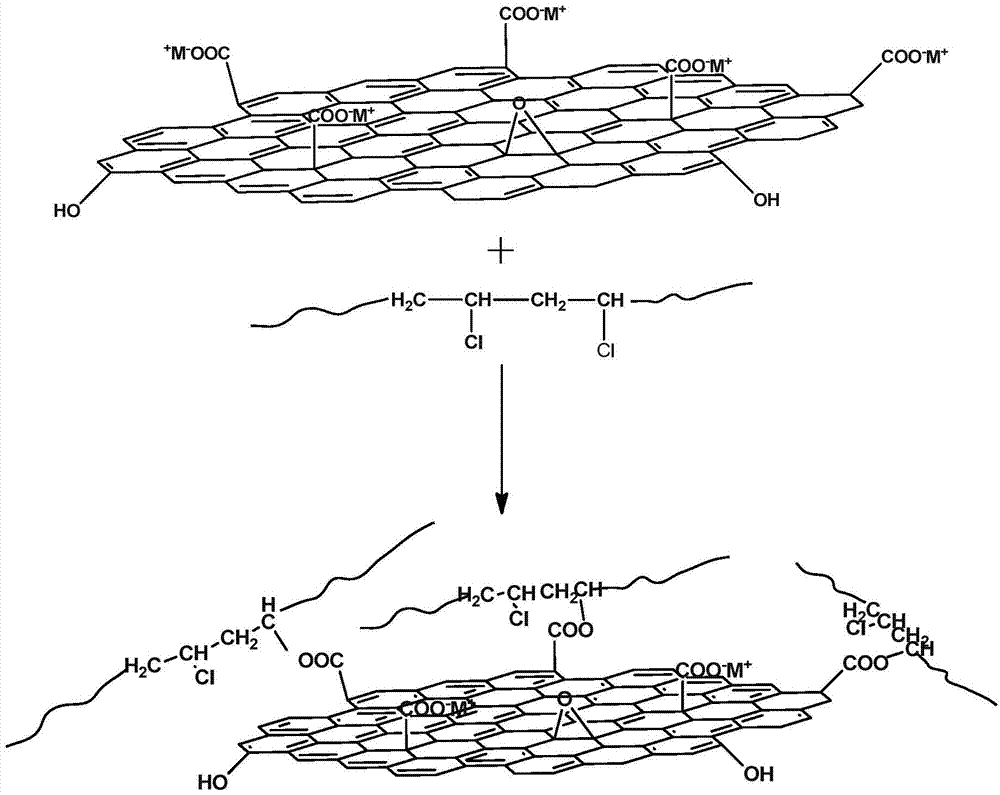

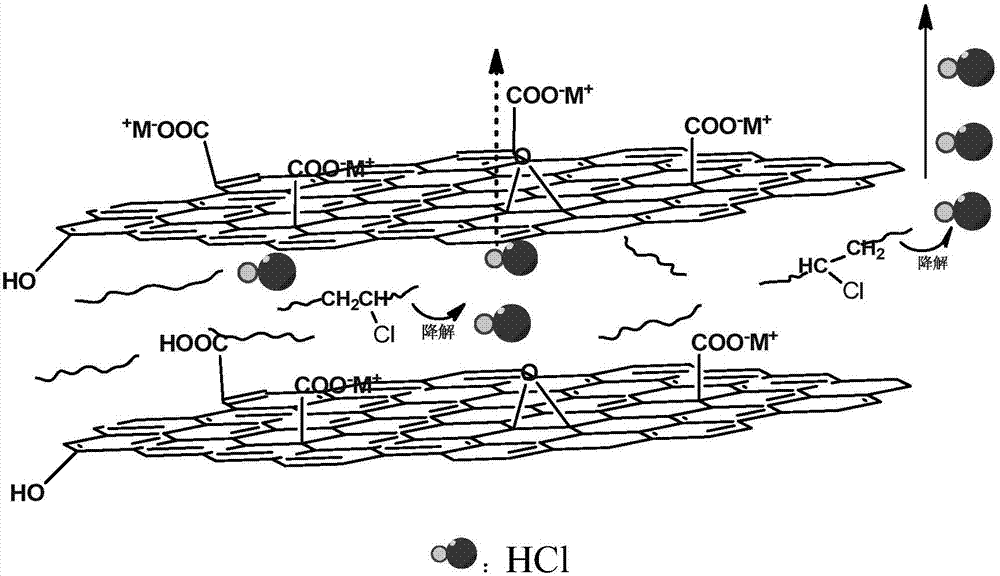

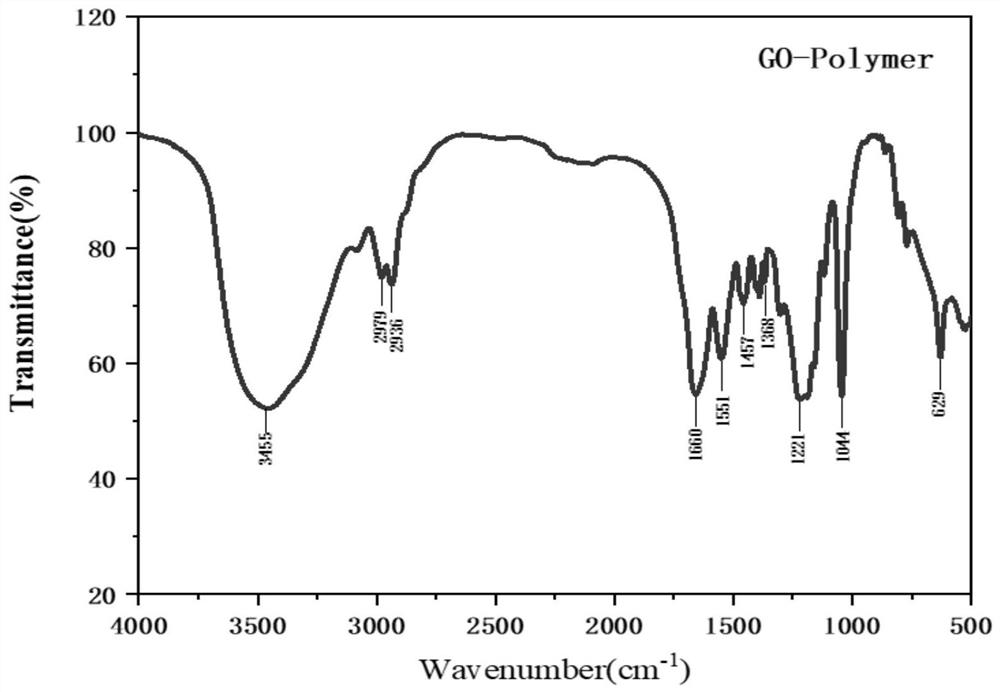

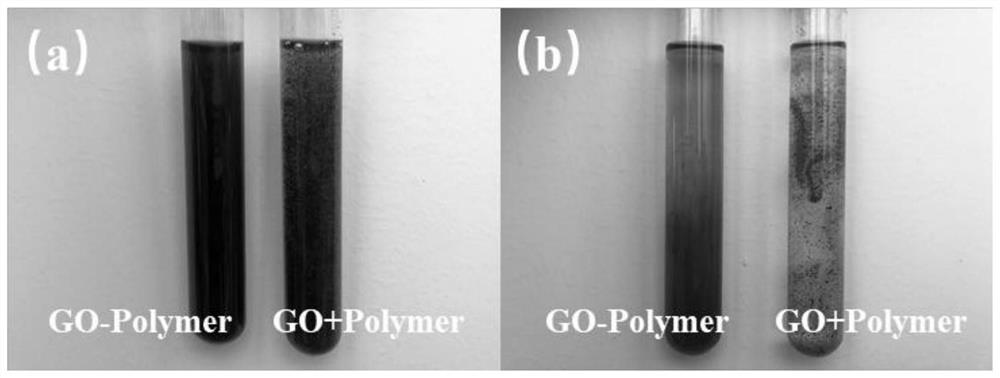

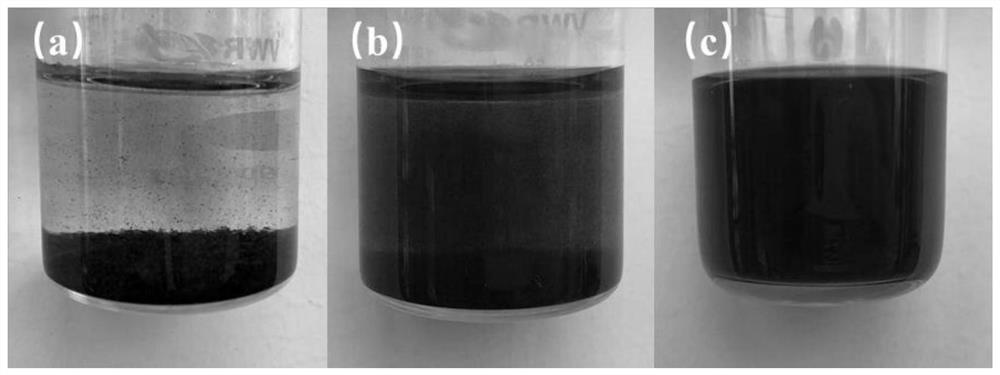

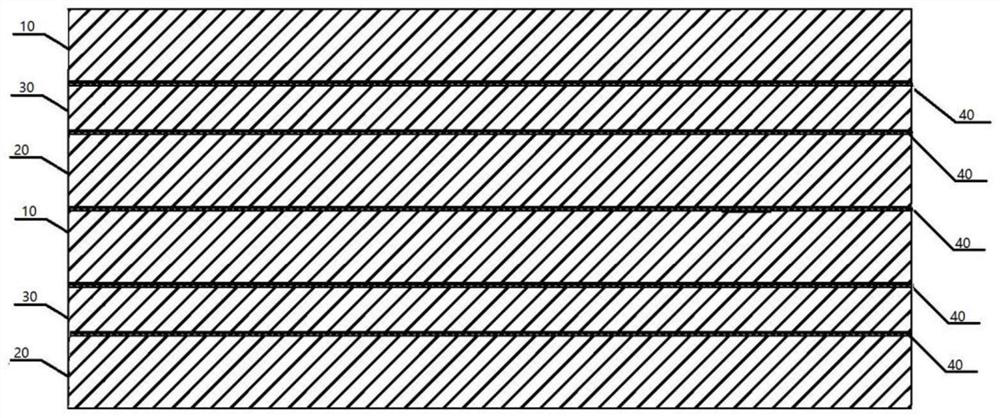

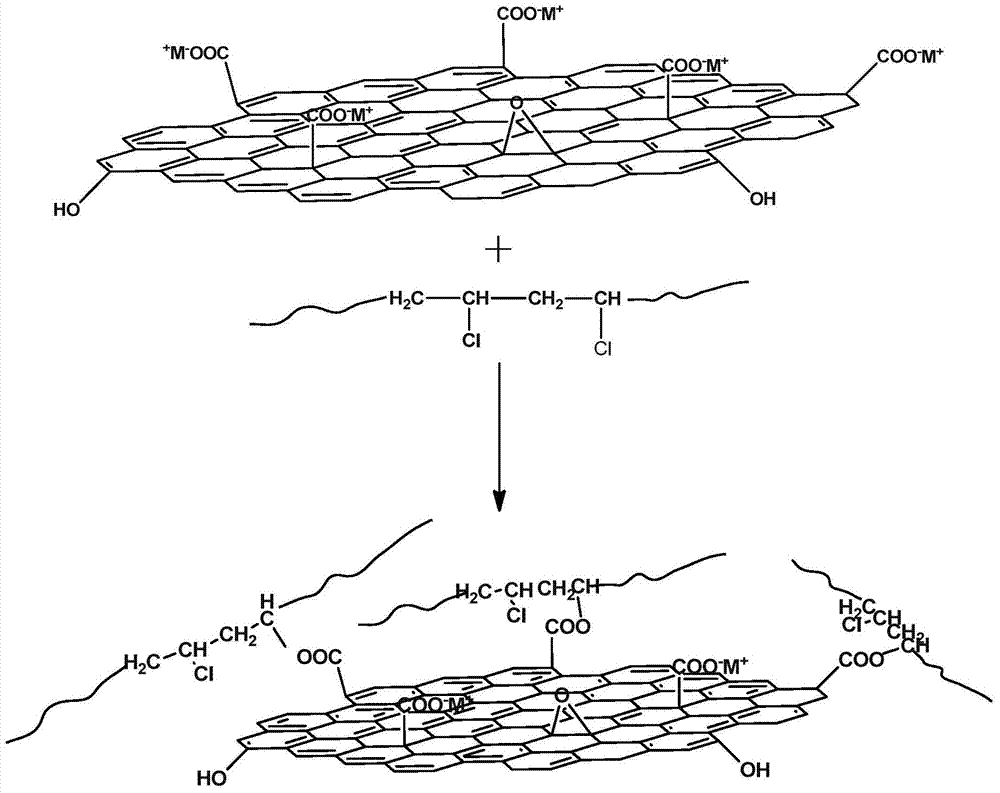

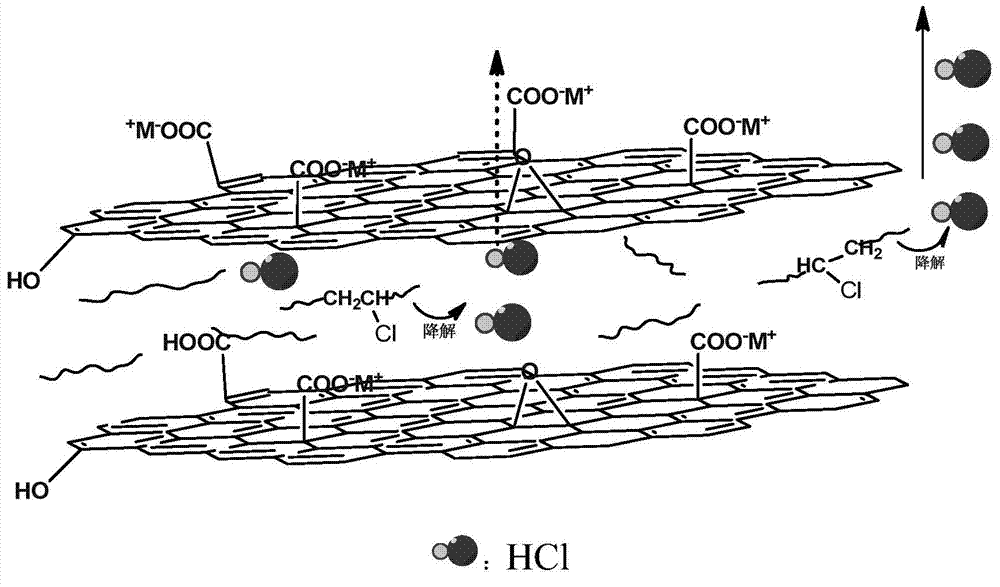

Oxidized graphene salt-based PVC environment-friendly composite stabilizer and preparation method thereof

The invention discloses an oxidized graphene salt-based PVC (polyvinyl chloride) environment-friendly composite stabilizer which comprises the following components in parts by weight: 50-90 parts of a main stabilizer and 10-50 parts of an auxiliary stabilizer, wherein the main stabilizer is a compound of oxidized graphene salt and metal soap salt and can be prepared by reacting oxidized graphene with excessive inorganic base to obtain solid oxidized graphene salt and compounding the solid oxidized graphene salt with the metal soap salt or by reacting oxidized graphene with inorganic base with the excess amount of 20%-50% and adding fatty acid into a reaction solution to neutralize incompletely reacted inorganic base. The compound stabilizer has a good heat stabilization effect, is superior to most of PVC nontoxic compound stabilizers reported in literatures on the aspect of dynamic and static stabilization time, has better reinforcing and toughening effects on PVC resin, can be used for improving the tensile strength and the impact toughness of PVC, increasing the Young modulus of PVC and the like, and has the advantages of simple and convenient preparation method, cheap and easily accessible raw materials, environmental friendliness and the like.

Owner:SOUTHWEST UNIV

High-toughness heat-resistant corrosion-resistant pre-hardened plastic die steel and preparation method thereof

The invention discloses high-toughness heat-resistant corrosion-resistant pre-hardened plastic die steel. According to the die steel, the ratio of elements such as Mn, Si, Cr and Sr are properly increased on the basis of the element ratio of the conventional pre-hardened plastic die steel, and meanwhile, the dosage of the other alloy elements is controlled, so that the mechanical properties and processability of alloy are improved further on the basis of guaranteeing the mechanical properties and processability of the conventional plastic die steel, and the pre-hardened plastic die steel has good toughness and hardness, is small in internal stress, and low in possibility of abrasion and corrosion cracking and can be used for pouring of various types of plastic parts; an added rare earth oxide cladded nano tungsten carbide composite modifier has good wettability with alloy liquid, so that a modification effect is uniform and stable, the reinforcing and toughening effects are remarkable and the crystal phase of the alloy is compact and fine; the die steel is simple and efficient in preparation method and short in manufacturing period, can effectively improve the surface quality of plastic parts and has extremely high production application value.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Modified gypsum-based whisker for reinforcing and toughening plastic and preparation method thereof based on emulsion polymerization

The invention discloses modified gypsum-based whisker for reinforcing and toughening plastic. A core-shell structure taking calcium sulfate whisker as a core and an elastomer as an outer coating layer can be applied to functional modification of plastic. According to the modified gypsum-based whisker disclosed by the invention, the calcium sulfate whisker is pretreated first, and the problem that whisker loses water and is disintegrated in a high-temperature extrusion process is effectively solved; then an elastomer is generated by an in-situ emulsion polymerization technology, and the surface of the calcium sulfate whisker is coated to form a core / shell structure taking calcium sulfate hemihydrate whisker as a core and the elastomer as a shell; the core / shell structure is used for modifying a PVC (Polyvinyl Chloride) hard material, and a good effect of reinforcing and toughening is realized obviously.

Owner:WUHAN UNIV OF TECH

Ultrahigh-temperature modified polymer well cementation fluid loss agent as well as preparation method and application thereof

PendingCN113651931AImprove performanceImprove mechanical propertiesDrilling compositionMeth-Unconventional oil

The invention discloses an ultrahigh-temperature modified polymer well cementation fluid loss agent as well as a preparation method and application thereof, and belongs to the technical field of oil and gas well cementation admixtures. The ultrahigh-temperature modified polymer well cementation fluid loss agent is prepared from the following raw materials in parts by weight: 0.1 to 2 parts of graphene oxide, 0.1 to 1 part of initiator, 12 to 48 parts of 2-acrylamido-2-methylpropanesulfonic acid, 3 to 24 parts of unsaturated amide, 2 to 12 parts of unsaturated carboxylic acid and 130 to 170 parts of water. The fluid loss agent provided by the invention has the advantages of stable performance, high temperature resistance (30-240 DEG C), salt saturation resistance, excellent fluid loss performance, high adaptability, capability of remarkably improving mechanical properties (strengthening and toughening) of set cement and the like, and can meet the requirements of well cementation technologies under complex working conditions of deep wells, ultra-deep wells, complex natural gas wells, unconventional oil and gas wells, gas storage wells and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-plasticity corrosion-resistant temperature-resistant pre-hardening plastic die steel and preparation method thereof

InactiveCN105177438AImprove mechanical properties and casting cutting performanceExcellent strength and wear resistance, high temperature oxidation and corrosion resistanceAlloy elementCorrosion resistant

The invention discloses a high-plasticity corrosion-resistant temperature-resistant pre-hardening plastic die steel, and according to the die steel, the ratio of the elements such as Mn, Mo, Cr and Ti are properly improved based on the element ratio of a conventional pre-hardening plastic die steel, meanwhile, the usage of other alloy elements is controlled, so that the mechanical properties and pouring cutting properties of the alloy are further improved on the basis of the mechanical properties and processability of the conventional plastic die steel, and the die steel has excellent strength, wear resistance, high temperature resistance and oxidation resistance and corrosion resistance, is better in plasticity, and easy to cut and form, can be used for pouring plastic parts of various types, moreover, a tissue structure of the die steel is further improved by an added rare earth oxide-cladded nano tungsten carbide composite modifier, so that a reinforcing and toughening effect is obvious, and the wettability with alloy fluid is better, and a metamorphism effect is uniform and stable; a preparation method of the die steel is simple and efficient, short in manufacturing period and capable of greatly improving the quality of plastic products and has high production and application value.

Owner:WUHU BAOYI AMUSEMENT EQUIP

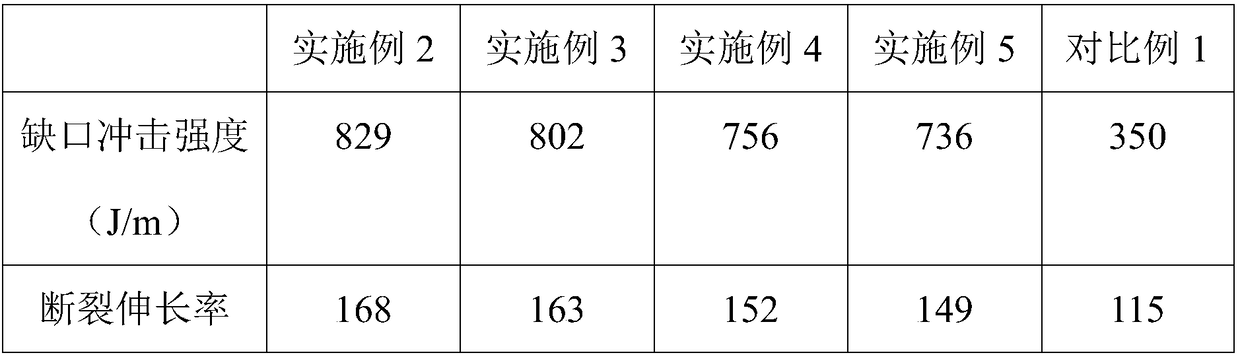

Acrylonitrile-butadiene-styrene (ABS) composite material for three-dimensional (3D) printing, and preparation method of ABS composite material

InactiveCN108129789AImprove processing fluidityImprove notched impact strengthAdditive manufacturing apparatusAntioxidantExtrusion Granulation

The invention discloses an acrylonitrile-butadiene-styrene (ABS) composite material for three-dimensional (3D) printing, and a preparation method of the ABS composite material, and relates to the technical field of 3D printing. The ABS composite material is prepared from the following raw materials in parts by weight: 70-80 parts of ABS resin, 7-15 parts of a maleic anhydride grafted toughening agent, 10-20 parts of cardanol, 1-3 parts of a lubricating agent, 1-3 parts of toner and 0.2-1 part of an antioxidant. According to the preparation method, the maleic anhydride grafted toughening agentand the cardanol are cooperatively used for reinforcing and toughening the ABS resin, and the processing fluidity of the ABS also can be improved; the maleic anhydride grafted toughening agent, the cardanol and the ABS resin are extruded and granulated after being subjected to internal mixing, and are then evenly mixed; after that, the mixture is matched with other components such as the lubricating agent, the toner and the antioxidant according to a reasonable ratio; the temperature in the process is reasonably optimized, and extrusion wire-drawing is performed. A prepared 3D printing consumable product is good in performance and has an obvious toughening effect.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

Light highly-thermal-fatigue-resistant pre-hardened plastic die steel and preparation method thereof

The invention discloses light highly-thermal-fatigue-resistant pre-hardened plastic die steel. According to the die steel, the ratio of elements such as Ni, Mn, Ti and V is properly increased on the basis of the element ratio of the conventional pre-hardened plastic die steel, and meanwhile, the dosage of the other alloy elements is controlled, so that the mechanical properties and processability of an alloy material are improved further on the basis of guaranteeing the mechanical properties of the conventional plastic die steel, and the pre-hardened plastic die steel is light, high in strength, good in abrasion resistance and corrosion resistance, good in thermal fatigue resistance, and low in possibility of generating surface defects, and can be used for pouring of various types of plastic parts; the structure of the die steel is refined through an added rare earth oxide-graphene oxide cladded nano tungsten carbide composite modifier, the interface compatibility among crystals is improved and reinforcing and toughening effects are remarkable; the die steel is simple and efficient in preparation method, short in manufacturing period, and durable, can effectively improve the surface quality of plastic parts and has extremely high production application value.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Anti-ultraviolet PET (Polyethylene Terephthalate) thermal shrinkage film

InactiveCN109181244AImprove mechanical propertiesImproves UV resistancePolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses an anti-ultraviolet PET (Polyethylene Terephthalate) thermal shrinkage film and relates to the technical field of novel materials. The anti-ultraviolet PET thermal shrinkage film contains butyl glucoside modified mullite having the mass fraction of 7.52-7.68%, wherein the maleic acid modified nano graphene having the mass fraction of 1.23-1.26% is doped in the butyl glucoside modified mullite. The PET thermal shrinkage film prepared according to the invention has excellent mechanical property, ultraviolet resistance and excellent barrier property.

Owner:马鞍山卓凡新材料科技有限公司

Preparation method of waste continuous silicon carbide fiber reinforced silicate ceramic

ActiveCN114085089AEfficient use ofImprove performanceCeramic materials productionCarbide siliconSic fiber

The invention discloses a preparation method of waste continuous silicon carbide fiber reinforced silicate ceramic, which comprises the following steps: firstly, taking waste continuous silicon carbide fiber as a raw material to obtain chopped silicon carbide fiber waste silk of which the surface is coated with a fiber protective layer; preparing a basic formula of a ceramic body, mixing the basic formula with the chopped silicon carbide fiber waste silk to obtain ceramic body slurry, and performing slip casting, glazing and final sintering to prepare the waste continuous silicon carbide fiber reinforced silicate ceramic. In the preparation process, the reinforcing and toughening effects of the waste continuous silicon carbide fibers are remarkable, the glaze surface of the prepared waste continuous silicon carbide fiber reinforced silicate ceramic is smooth and free of obvious air holes, the water absorption rate is smaller than 2.2%, and the bending strength of a green body is larger than 123 MPa.

Owner:福建立亚新材有限公司

High-temperature steam corrosion resistant pre-hardened plastic die steel and preparation method thereof

InactiveCN105200331ASimple manufacturing methodImprove organizational structureRare earthMechanical property

The invention discloses high-temperature steam corrosion resistant pre-hardened plastic die steel. According to the die steel, the matching ratio of Mn, Gr, Zr and other elements is increased on the basis of the matching ratio of elements of the traditional pre-hardened plastic die steel, the use amount of other alloy elements is controlled, the corrosion resistance of hot steam resistant components of an alloy is further improved on the basis of the fact that the mechanical property and processability of the traditional plastic die steel are guaranteed, the possibility of fatigue fracture is low, the requirements for pouring various plastic components can be met, the organization structure of the die steel is further improved by virtue of the added rare earth oxide coated nano tungsten carbide composite modifier, the reinforcing and toughening effect is remarkable, the wetting property with molten metal is better, and the modification effect is uniform and stable. The preparation method of the die steel is simple and efficient, the manufacture period is short, the die steel is durable in use, the surface of a die block is smooth and free of cracks, and the processing quality of a plastic die is greatly improved.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Improved type hosepipe

The invention discloses an improved type hosepipe prepared from the following raw materials in parts by weight: 25-50 parts of polyvinyl chloride resin, 3-6 parts of 1-hydroxyethyl-2-heptadecenylimidazoline, 5-10 parts of polyvinyl butyral ester, 3-6 parts of precipitated barium sulfate, 1-3 parts of triclosan, 2-5 parts of polyoxyethylene alkyl phenyl ether, 2-5 parts of benzotriazole, 4-8 parts of o-phthalic anhydride, 2-7 parts of antimony trioxide, 8-16 parts of polycarbonate, 2-4 parts of nano calcium carbonate, 3-7 parts of calcium aluminate, and 3-6 parts of citric acid. The invention provides the wear-resistant aging-resistant improved type hosepipe having the advantages of excellent stability, excellent heat resistance, strong impact resistance and obvious reinforcing and toughening effects, and enabling low temperature resistance, flexibility and electrostatic resistance to meet low temperature transport.

Owner:QINGDAO JISHUNLONG TRADING

Easy-to-demould, high-hardness and pre-hardened plastic mould steel, and preparation method thereof

The invention discloses an easy-to-demould, high-hardness and pre-hardened plastic mould steel. The ratio of Ni, Cr, Cu, Ta and other elements in the steel is appropriately increased on the basis of a conventional pre-hardened plastic mould steel ratio, meanwhile, the consumption of other alloy elements is controlled, so that the mechanical property and the processability of an alloy material are further improved on the basis of ensuring the mechanical property of the traditional plastic mould steel. The plastic mould steel provided by the invention is high in hardness and crack resistance, dense in organization, smooth in surface and unlikely to damage; plastic can realize demoulding easily; through the addition of a rare earth oxide-oxidized graphene cladded nano-tungsten carbide compound modifier, the organizational structure of the mould steel is refined, the interface compatibility among crystals is improved, the toughening enhancing effect is significant, and the modification effect is uniform and stabilize. A preparation method for the mould steel is simple, efficient, and short in manufacturing cycle; the steel is durable and has a great production application value.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Method for quickly preparing nano-cellulose reinforced graphite material

InactiveCN110372409ALow costRemarkable effect of strengthening and tougheningWater bathsReaction temperature

The invention discloses a method for quickly preparing a nano-cellulose reinforced graphite material. The method comprise the following specific steps: 1) dispersing nano-cellulose in an ethanol aqueous solution, then adding high-purity ultra-fine graphite powder, and placing the mixture into an ultrasonic water bath for ultrasonic oscillation mixing to obtain precursor slurry; 2) pouring the precursor slurry into a Brinell funnel, and carrying out suction filtration to obtain a filter cake; 3) carrying out vacuum drying on the filter cake to prepare a blank body; 4) placing the raw material blank body into a graphite mold, placing the graphite mold in a direct current hot press sintering device, applying pressure and direct current voltage on two sides by electrodes, controlling the current to obtain an appropriate reaction temperature, and completing a reaction; and 5) carrying out cooling to obtain the nano-cellulose reinforced graphite material.

Owner:苏州山人纳米科技有限公司

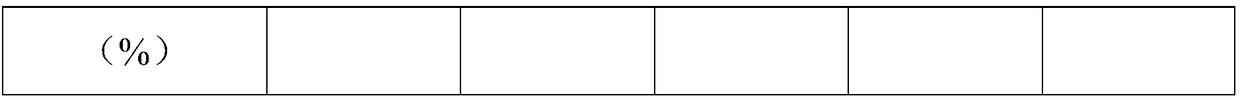

Greenhouse film for grape planting and preparation method thereof

PendingCN114103366ARich reservesGood fatigue resistanceAgricultural articlesClimate change adaptationEnvironmental geologyPhotochromism

The invention discloses a greenhouse film for grape planting and a preparation method thereof, the greenhouse film comprises a plurality of stacked degradable material layers, and the degradable material layers are PLA resin layers and PBAT resin layers which are sequentially arranged at intervals; the color-matching film is characterized in that the PLA resin layer and the PBAT resin layer have different color-matching functions; a grid reinforcing layer is also arranged between the PLA resin layer and the PBAT resin layer. The organic photochromic particles and the inorganic photochromic particles are effectively combined, so that the greenhouse film presents different colors along with illumination, and the overall absorption effect on sunlight is good. The whole greenhouse film is made of environment-friendly materials, so that the greenhouse film is harmless to the environment and has extremely high popularization value.

Owner:ZHENGZHOU FRUIT RES INST CHINESE ACADEMY OF AGRI SCI

PVC environment-friendly composite stabilizer based on graphene oxide salt and preparation method thereof

The invention discloses an oxidized graphene salt-based PVC (polyvinyl chloride) environment-friendly composite stabilizer which comprises the following components in parts by weight: 50-90 parts of a main stabilizer and 10-50 parts of an auxiliary stabilizer, wherein the main stabilizer is a compound of oxidized graphene salt and metal soap salt and can be prepared by reacting oxidized graphene with excessive inorganic base to obtain solid oxidized graphene salt and compounding the solid oxidized graphene salt with the metal soap salt or by reacting oxidized graphene with inorganic base with the excess amount of 20%-50% and adding fatty acid into a reaction solution to neutralize incompletely reacted inorganic base. The compound stabilizer has a good heat stabilization effect, is superior to most of PVC nontoxic compound stabilizers reported in literatures on the aspect of dynamic and static stabilization time, has better reinforcing and toughening effects on PVC resin, can be used for improving the tensile strength and the impact toughness of PVC, increasing the Young modulus of PVC and the like, and has the advantages of simple and convenient preparation method, cheap and easily accessible raw materials, environmental friendliness and the like.

Owner:SOUTHWEST UNIV

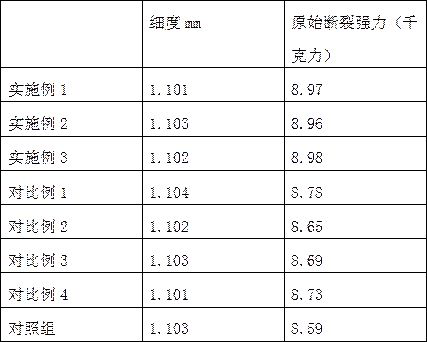

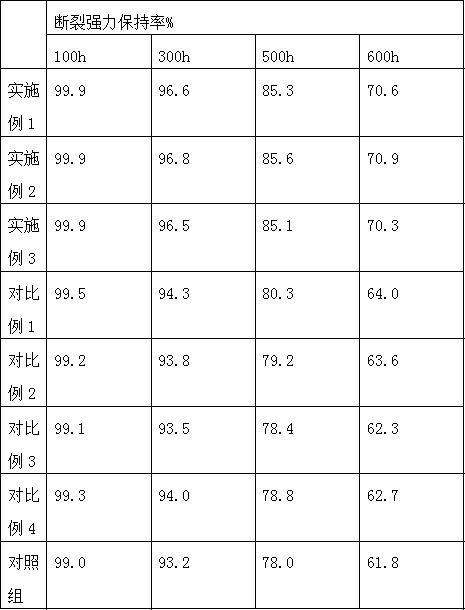

A fishing net with excellent aging resistance

ActiveCN108739690BInhibition of photochemical reactionsIncreased durabilityFishing netsMonocomponent polyolefin artificial filamentTriethoxysilaneFishery

The invention discloses a fishing net with excellent ageing-resistant performance. 2-diphenylphosphine ethyltriethoxysilane grafted oxidized graphene modifies polyethylene under the melting condition,master batches are prepared, the obtained master batches are made into fishing net threads, and the fishing net is woven by using the fishing net threads; according to the fishing net, the 2-diphenylphosphine ethyltriethoxysilane grafted oxidized graphene modifies the polyethylene fishing net, significant reinforcing and toughening effects can be achieved, and the ageing-resistant performance isimproved.

Owner:威海市世一网业有限公司

Preparation method of CFRP cloth constrained hybrid fiber lightweight aggregate concrete

InactiveCN109987901AGood crack propagationGood resistance to crack propagationLaminationLamination apparatusFiberCompressive strength

The invention discloses a preparation method of CFRP cloth constrained hybrid fiber lightweight aggregate concrete. The method provided by the invention combines a CFRP cloth, hybrid fibers and lightweight aggregate concrete, fully exerts lateral restraint ability of the CFRP and a good toughing effect of the hybrid fibers, and comprehensively improves the compressive strength, ductility and splitting strength of the concrete; and when the method is applied to a project, the quality, durability and service life of the project are greatly improved, and the method brings good economic and socialbenefits.

Owner:CHANGAN UNIV

High-chromium anticorrosion high-precision pre-hardened plastic die steel and manufacturing method thereof

InactiveCN105256237AGood dimensional stabilityImprove organizational structureRare earthThermal stability

The invention discloses high-chromium anticorrosion high-precision pre-hardened plastic die steel and a manufacturing method thereof. According to the die steel, the ratios of Cr, Mn, Zn, Y and other elements are increased properly based on the element ratio of traditional pre-hardened plastic die steel, meanwhile the consumption of other alloy elements is controlled, and the mechanical property and machining property of an alloy material are further improved on the basis that the mechanical property of the traditional plastic die steel is guaranteed; the die steel is high in heat stability, the die size stability is good, and a plastic part higher in precision can be obtained; and a nano-sized tungsten carbide composite alterant is wrapped by added rare earth oxide-oxidized graphene so that the organizational structure of the die steel can be refined, the interfacial compatibility among crystals is improved, the toughening and reinforcing effect is remarkable, and the metamorphism effect is even and stable. The die steel is compact in surface, resistant to wear and corrosion and durable. The manufacturing method for the high-chromium anticorrosion high-precision pre-hardened plastic die steel is simple, efficient, short in manufacturing cycle and very high in production application value.

Owner:WUHU BAOYI AMUSEMENT EQUIP

A kind of preparation method of graphene reinforced nickel-aluminum alloy matrix composite material

InactiveCN108531780BSolving Difficult Difficult PuzzlesEasy to controlMetallic aluminumNickel substrate

The invention relates to a preparation method of a graphene strengthened nickel-aluminum alloy based composite and belongs to the technical field of metal based composites. In the method, by taking asolid carbon source as a precursor of graphene, the problem that the graphene is difficult to disperse is solved; by utilizing metal aluminum to regulate the solid solution and precipitation process of carbon atoms in a nickel matrix in the solid solution process in the nickel matrix, growth of the graphene is controlled, the graphene with a controllable layer number is prepared, and the graphene,growing in situ, is good in interface bonding force with a nickel-aluminum alloy matrix to have remarkable strengthening and toughening effects to the nickel-aluminum alloy matrix; and in addition, the growth process of the graphene and the densification sintering process of the nickel-aluminum matrix are performed at one step, the preparation process is simple, is good in controllability and issuitable for mass production.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

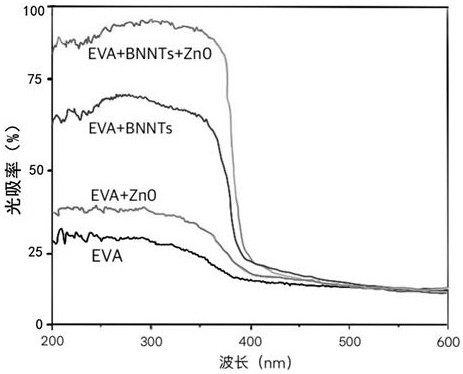

High-elasticity lightweight ethylene-vinyl acetate copolymer based composite material having strong ultraviolet absorption and used for cap eyebrow tongue core and preparation method thereof

The invention discloses a high-elasticity lightweight ethylene-vinyl acetate copolymer based composite material having strong ultraviolet absorption and used for a cap eyebrow tongue core and a preparation method thereof, and relates to the technical field of composite materials. The high-elasticity lightweight ethylene-vinyl acetate copolymer based composite material is specifically prepared from the following components in percentage by mass: 70-98 wt% of EVA particles, 1.5-5 wt%of EVA foaming master batch, 0.05-25 wt%of BNNTs powder, 0.5-1.5 wt%of ZnO powder and 0.1-0.5 wt% of silicone oil, the composite material is foamed, loose and porous, the density is 0.3-0.6 g / cm<3>, the elastic recovery rate is not lower than 98%, the tensile strength is not lower than 3 MPa, and the ultraviolet absorptivity is not lower than 50%. According to the invention, an inorganic matrix and an organic substrate are highly fused, so that the material performance is stable and uniform; the composite material can keep light weight, high elasticity and high strength at the same time, and is more convenient to fold, store and carry without deformation or fracture as a cap eyebrow tongue core material; and the absorptivity of the composite material to ultraviolet rays is obviously enhanced.

Owner:NANTONG GUANZHOU INT TRADE CO LTD

Preparation method of polypropylene reinforced plasticized modifier

InactiveCN101585977BHigh strengthImprove toughnessPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPolymer scienceRoom temperature

The invention relates to a preparation method of polypropylene reinforced plasticized modifier, comprising the following steps: 1) performing the surface lipophilic treatment: selecting lipophilic additive and silicon dioxide wherein the weight of the lipophilic additive accounts for 0.5-2.5% of the weight of the silicon dioxide; preparing lipophilic additive isopropanol solution with concentration of 0.05-0.5mol / L and adding the solution into the silicon dioxide, uniformly mixing the mixture and heating the mixture for 2-4 hours at 50-60 DEG C to obtain the standby A component; 2) selecting polymer emulsion and the standby A component in ratio of 1:1; stirring the standby A component at room temperature and gradually adding the standby A component into the polymer emulsion and uniformly stirring and mixing the mixture; stopping stirring and spray drying the mixture to obtain the composite powder material and extruding and granulating the composite powder material to obtain the polypropylene reinforced plasticized modifier. The modifier can increase the intensity and toughness of the polypropylene and has no obvious effect on melt flow.

Owner:WUHAN UNIV OF TECH

A kind of water-based environmental protection paint and preparation method thereof

ActiveCN110437698BImprove hydrophilicityImprove water resistanceCoatingsModified carbonAcrylic adhesive

The invention relates to a water-based environmental protection coating and a preparation method thereof, belonging to the field of coatings. The water-based environment-friendly paint of the invention is prepared by using silicone-modified acrylic latex as the main component, together with inorganic fillers and other additives. Using alkylation-modified carbon nanotubes and nano-silica as inorganic fillers, the combined use of carbon nanotubes and nano-silica can form a synergistic reinforcement of points and lines, and a uniform coating can be formed when the coating is very thin. Smooth film Alkylation-modified carbon nanotubes and nano-silica can effectively avoid the agglomeration of fillers and effectively improve the dispersion of inorganic fillers in coating resins. The alkylation-modified filler also has the function of a defoamer, so the water-based environmental protection coating of the present invention does not need to add other defoamers. The water-based environmental protection paint prepared by the invention has excellent mechanical properties, adhesion, hydrophilicity and water resistance. The preparation method is simple and feasible, has good stability and repeatability, and is easy to realize industrialized production.

Owner:付江辉

Crack-resistant and high-dimensional-stability prehardened plastic die steel and preparation method thereof

InactiveCN105177443AImprove alloy mechanical and processing propertiesGood thermal conductivityAlloy elementCorrosion resistant

The invention discloses crack-resistant and high-dimensional-stability prehardened plastic die steel. The proportions of elements, such as Mn, Cr, Cu and Sn, in the die steel are increased appropriately on the basis of the proportions of elements of conventional prehardened plastic die steel, moreover, the usages of other alloy elements are controlled, the mechanical property and machinability of the alloy are further improved on the basis of ensuring the mechanical property and machinability of the conventional plastic die steel, the die steel has good thermal conductivity and good surface lubricity, and is corrosion-resistant and anti-sticking, the surface is smooth and clean, and cannot be cracked easily, precision is high, the die steel is applicable to the casting of a variety of plastic parts, the wettability of an added rare earth oxide-coated nano-tungsten carbide compound modifier with the molten alloy is good, the structure of the die steel is refined, the toughening effect is enhanced remarkably, and the modification effect is uniform and stable; the preparation method of the die steel is simple and highly efficient, the manufacturing period is short, the surface quality of plastic parts is improved greatly, and the die steel has high production and application value.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com