Greenhouse film for grape planting and preparation method thereof

A greenhouse film and grape technology, which is applied in the direction of botany equipment and methods, chemical instruments and methods, applications, etc., can solve the problems of short service life, difficult degradation of greenhouse film, single color matching, etc., and achieve sensitive color change, abundant reserves, Good fatigue resistance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

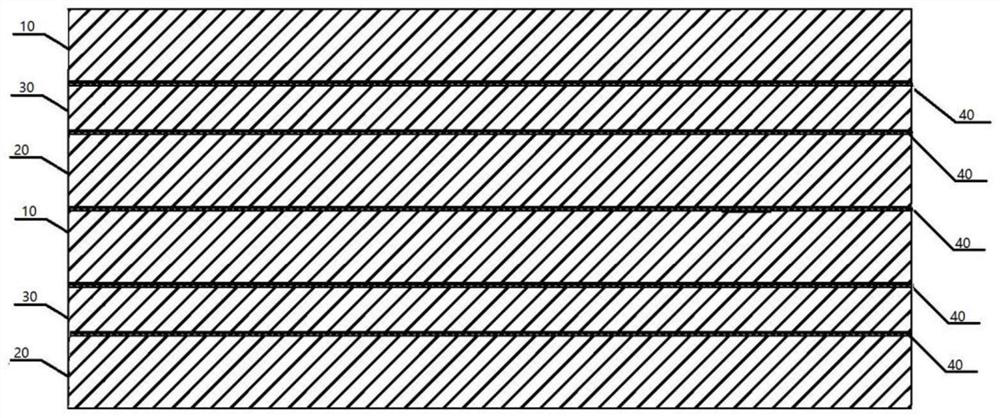

[0039] Example 1: See figure 1 , a greenhouse film for grape planting, comprising two stacked degradable material layers, characterized in that: the degradable material layer is a PLA resin layer (10) and a PBAT resin layer (20) arranged at intervals in sequence; It is characterized in that: said PLA resin layer (10) and said PBAT resin layer (20) have different toning functions, and said PLA resin (10) and said PBAT resin layer (20) A grid reinforcement layer (30) is also provided; water-based glue (40) is provided between the above-mentioned layers.

[0040] Preferably in this embodiment, the PLA resin layer is composed of WO 3 and MoO 3 Resin layer of composite toner particles.

[0041] In this embodiment, preferably, the PBAT resin layer is a resin layer containing a diarylethene photochromic compound.

[0042] Preferably in this embodiment, the diarylethene photochromic compound is 2,3-bis(2,4,5-trimethyl-3-thienyl) maleic anhydride.

[0043] Preferably in this embod...

Embodiment 2

[0059] Embodiment 2: In this embodiment, a kind of greenhouse film that is used for grape planting comprises three layers of stacked degradable material layers, it is characterized in that: described degradable material layer is PLA resin layer (10) and PBAT resin Layers (20) are arranged at intervals successively; it is characterized in that: the described PLA resin layer (10) and the described PBAT resin layer (20) have different toning functions, and the described PLA resin (10) and the described A grid reinforcement layer (30) is also arranged between the PBAT resin layers (20); water-based glue (40) is arranged between the above-mentioned layers.

[0060] Preferably in this embodiment, the PLA resin layer is composed of WO 3 and MoO 3 Resin layer of composite toner particles.

[0061] In this embodiment, preferably, the PBAT resin layer is a resin layer containing a diarylethene photochromic compound.

[0062] Preferably in this embodiment, the diarylethene photochromi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com