A kind of water-based environmental protection paint and preparation method thereof

An environmentally friendly coating, water-based technology, applied in the direction of coating, etc., can solve the problems of limited application, poor decoration of substrates, and high adhesion requirements, etc., and achieve excellent mechanical properties, good stability, and simple and feasible preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

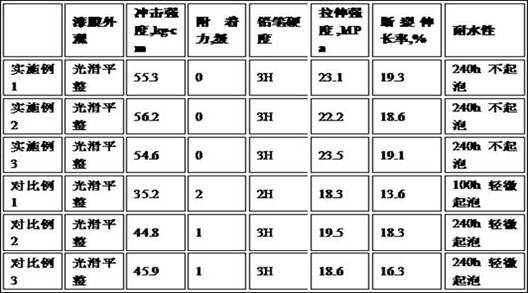

Examples

Embodiment 1

[0033] The invention provides a kind of water-based environmental protection paint, is made by the raw material of following weight part:

[0034] 50 parts of silicone modified acrylic latex;

[0035] Alkylation modified filler 20 parts;

[0036] 5 parts of polyvinyl butyral;

[0037] 5 parts of polydimethylsiloxane;

[0038] 20 parts of water.

[0039] The preparation method of above-mentioned water-based environmental protection coating comprises the following steps:

[0040] (1) Preparation of silicone-modified acrylic latex: Add 12.5kg of sodium lauryl sulfate and 12.5kg of allyl octylphenol polyoxyethylene ether to the reaction kettle in sequence, fully dissolve with 37.5kg of deionized water, and stir While slowly adding the monomer mixture (the monomer mixture includes 0.83kg methyl acrylate, 0.68kg acryloyl morpholine, 0.56kg hydroxyethyl acrylate and 0.72kg vinyltrimethoxysilane), stir well to obtain a pre-emulsion. Take 0.65kg of 3~5wt% ammonium sulfate aqueous ...

Embodiment 2

[0048] The invention provides a kind of water-based environmental protection paint, is made by the raw material of following weight part:

[0049] 60 parts of silicone modified acrylic latex;

[0050] Alkylation modified filler 28 parts;

[0051] 5 parts of polyvinyl butyral;

[0052] 5 parts of polydimethylsiloxane;

[0053]5 parts of diacetone alcohol;

[0054] 25 parts of water.

[0055] The preparation method of above-mentioned water-based environmental protection coating comprises the following steps:

[0056] (1) Preparation of silicone-modified acrylic latex: Add 12.5kg of sodium lauryl sulfate and 13.2kg of allyl octylphenol polyoxyethylene ether to the reaction kettle in sequence, fully dissolve with 49kg of deionized water, and stir Slowly add the monomer mixture (the monomer mixture includes 1.11kg methyl acrylate, 0.91kg acryloylmorpholine, 0.75kg hydroxyethyl acrylate and 0.96kg vinyltrimethoxysilane), and stir well to obtain a pre-emulsion. Take 1.18kg of 3...

Embodiment 3

[0064] The invention provides a kind of water-based environmental protection paint, is made by the raw material of following weight part:

[0065] 70 parts of silicone modified acrylic latex;

[0066] Alkylation modified filler 35 parts;

[0067] 9 parts of polyvinyl butyral;

[0068] 11 parts of diacetone alcohol;

[0069] 30 parts of water.

[0070] The preparation method of above-mentioned water-based environmental protection coating comprises the following steps:

[0071] (1) Preparation of silicone-modified acrylic latex: Add 12.5kg of sodium lauryl sulfate and 15kg of allyl octylphenol polyoxyethylene ether to the reaction kettle in sequence, fully dissolve with 75kg of deionized water, and slowly Add the monomer mixture (the monomer mixture includes 1.39kg methyl acrylate, 1.14kg acryloylmorpholine, 0.94kg hydroxyethyl acrylate and 1.20kg vinyltrimethoxysilane), and stir well to obtain a pre-emulsion. Take 2.14kg of 3~5wt% ammonium sulfate aqueous solution and slow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com