High-elasticity lightweight ethylene-vinyl acetate copolymer based composite material having strong ultraviolet absorption and used for cap eyebrow tongue core and preparation method thereof

A technology of vinyl acetate copolymer and composite materials, which is applied in the field of composite materials, can solve the problems of heavy brow core, poor ultraviolet absorption effect, poor elasticity and other mechanical and physical properties, etc., to reduce weight, improve comfort, The effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Taking a batch of 10 kg composite material as an example, the raw material components of the composite material are: 9.8kg of EVA particles, 0.005kg of BNNTs powder, 0.05kg of ZnO powder, 0.28kg of EVA foam masterbatch, and 0.01kg of silicone oil.

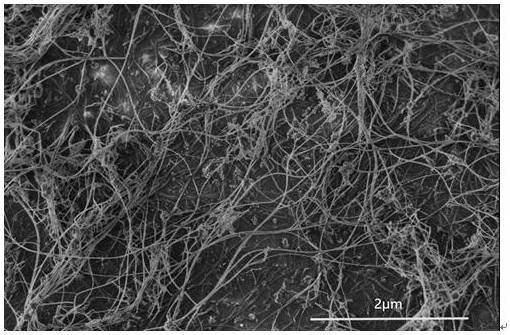

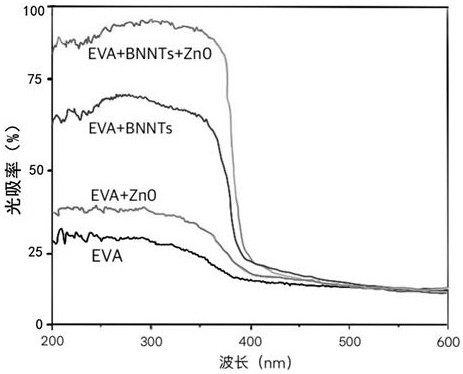

[0041] The VA content of the EVA particle raw material is not less than 16%; BNNTs are multi-walled boron nitride nanotubes with an aspect ratio of more than 1000:1. The SEM morphology of BNNTs is as follows figure 1 Shown; ZnO powder particle size is nanometer to submicron.

[0042] The composites were prepared as follows:

[0043] S1. Weigh various raw materials respectively according to the basic formula;

[0044] S2. Measure 0.5L of N,N-dimethylformamide (DMF) solvent according to the ratio of BNNTs and DMF solvent 1:100g / mL, add BNNTs powder into the DMF solvent, seal it, stir it mechanically or magnetically for 2 hours, and then After ultrasonic dispersion for 4 hours, a mixed solution was obtained;

[0045] S3. Add...

Embodiment 2

[0050] Taking a batch of 10 kg composite material as an example, the raw material components of the composite material are: 9.43kg of EVA particles, 0.3kg of BNNTs powder, 0.1kg of ZnO powder, 0.15kg of EVA foam masterbatch and 0.02kg of silicone oil.

[0051] The VA content of the EVA particle raw material is not less than 16%; BNNTs are multi-walled boron nitride nanotubes with an aspect ratio of more than 1000:1. The SEM morphology of BNNTs is as follows figure 1 Shown; ZnO powder particle size is nanometer to submicron.

[0052] The preparation steps of the composite material are the same as in Example 1, the difference being that in step S2, 30L of DMF solvent is measured according to the ratio of BNNTs to DMF solvent 1:100g / mL; The final temperature is in a screw extruder at 190°C.

[0053] The resulting composite material sheet is loose and porous, and the density is 0.557g / cm 3 , the hardness value is 27HD; according to the GB / T1040.2-2006 standard, the gauge length ...

Embodiment 3

[0055] Taking a batch of 10 kg composite material as an example, the raw material components of the composite material are: 8.7kg of EVA particles, 0.7kg of BNNTs powder, 0.07kg of ZnO powder, 0.5kg of EVA foam masterbatch and 0.03kg of silicone oil.

[0056] The VA content of EVA particle raw materials is not less than 16%, and the SEM morphology of BNNTs is as follows figure 1 Shown; BNNTs are multi-walled boron nitride nanotubes with an aspect ratio of more than 1000:1; ZnO powder particle size is nanometer to submicron.

[0057] Composite material preparation steps are the same as in Example 1, the difference is that in step S2, 52.5 L of DMF solvent is measured according to the ratio of BNNTs to DMF solvent 1:75g / mL; In a screw extruder with a temperature of 190°C after heating.

[0058] The resulting composite material sheet is loose and porous, and the density is 0.300g / cm 3 , the hardness value is 29HD; according to the GB / T1040.2-2006 standard, the gauge length of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com