Modified polypropylene material and preparation method thereof

A technology of polypropylene material and polypropylene powder, which is applied in the field of modified polypropylene material and its preparation, can solve the problems of adverse effects on the mechanical properties of modified polypropylene material, improve the thermal deformation temperature and the effect of electrical and thermal conductivity, and ensure stability properties, and the effect of increasing the thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The modified polypropylene material of the present embodiment is made up of the following components by weight:

[0026] The polypropylene powder resin of 25kg, the graphene of 0.25kg, the composite antioxidant of 0.1kg (made up of 0.025kg antioxidant 1010 and 0.075kg antioxidant 168).

[0027] The preparation method of above-mentioned modified polypropylene material has the following steps:

[0028] (1) Pour the bulk polymerized polypropylene powder, modifier, compatibilizer and composite antioxidant weighed according to the formula into a mixer and mix at a low speed for 4 minutes, and then discharge to obtain a mixed material;

[0029] (2) Feed the mixed material into a twin-screw extruder for melt extrusion, cut the extruded strip into pellets, cool it with water, and obtain a modified polypropylene material through drying treatment.

[0030] In the above-mentioned steps (2), the temperature in each district of the twin-screw extruder is: T 1 =150°C, T 2 =160°C, ...

Embodiment 2~ Embodiment 6

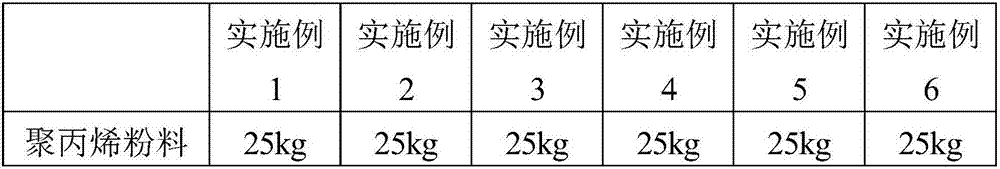

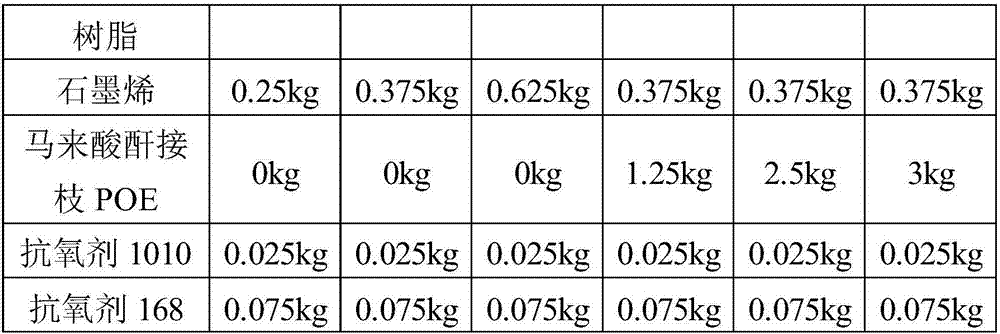

[0032] The preparation method of the modified polypropylene material of each example is the same as that of Example 1, the difference lies in the weight ratio of each component, see Table 1 for details.

[0033] Table 1: The formula ratio of embodiment 1~6

[0034]

[0035]

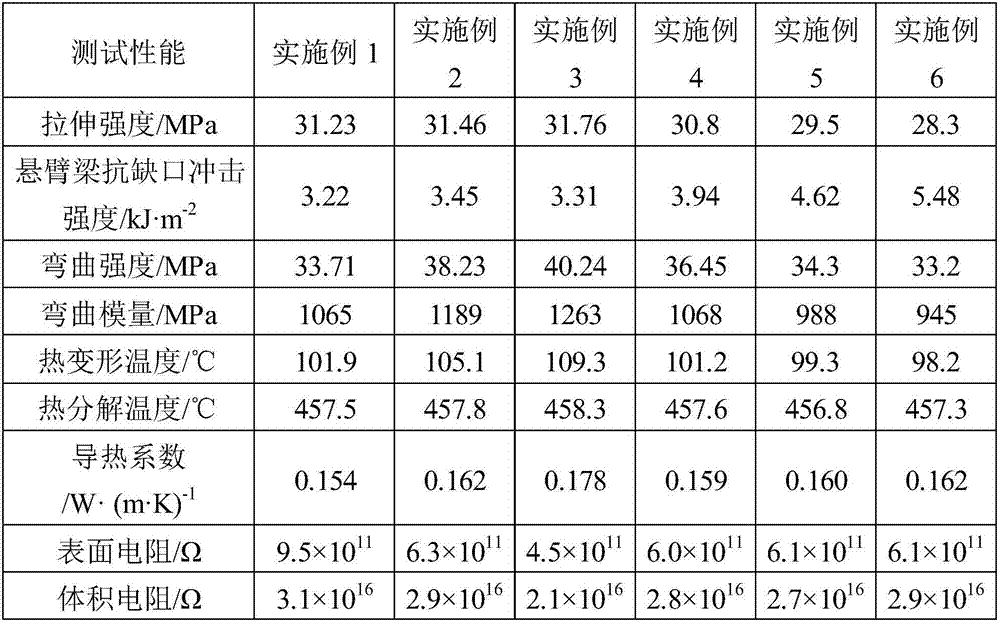

[0036] The modified polypropylene material obtained in Examples 1 to 6 was injected into a standard sample with an injection molding machine, and the mechanical properties of the standard sample were tested according to national standards. The test results are shown in Table 2.

[0037] Table 2: Test results of modified polypropylene materials prepared by the recipes of Examples 1 to 6

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com