PVC environment-friendly composite stabilizer based on graphene oxide salt and preparation method thereof

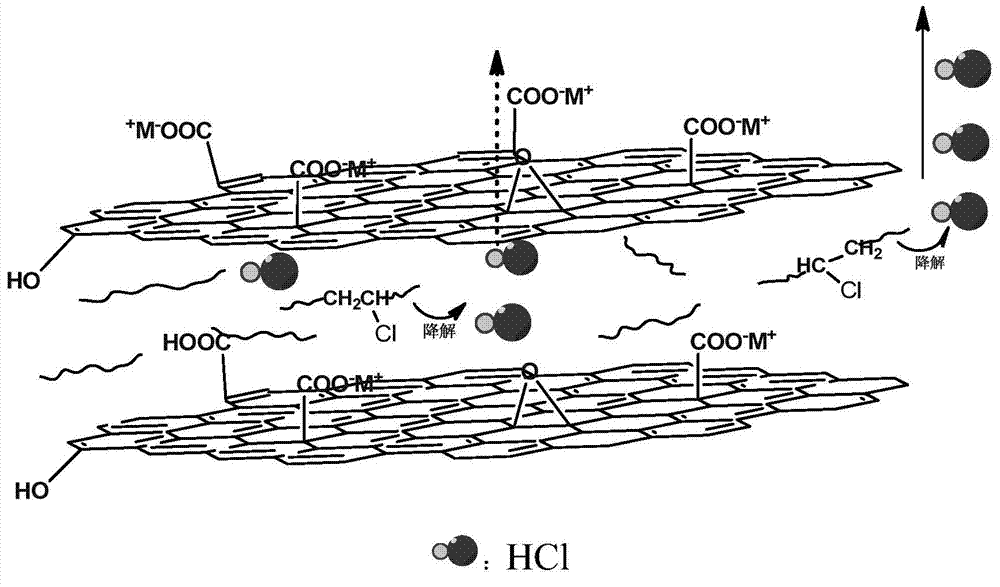

A compound stabilizer and graphene salt technology, which is applied in the chemical field, can solve the problems of thermal stability that have not been reported in the research, achieve good thermal stability, improve tensile strength, and the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

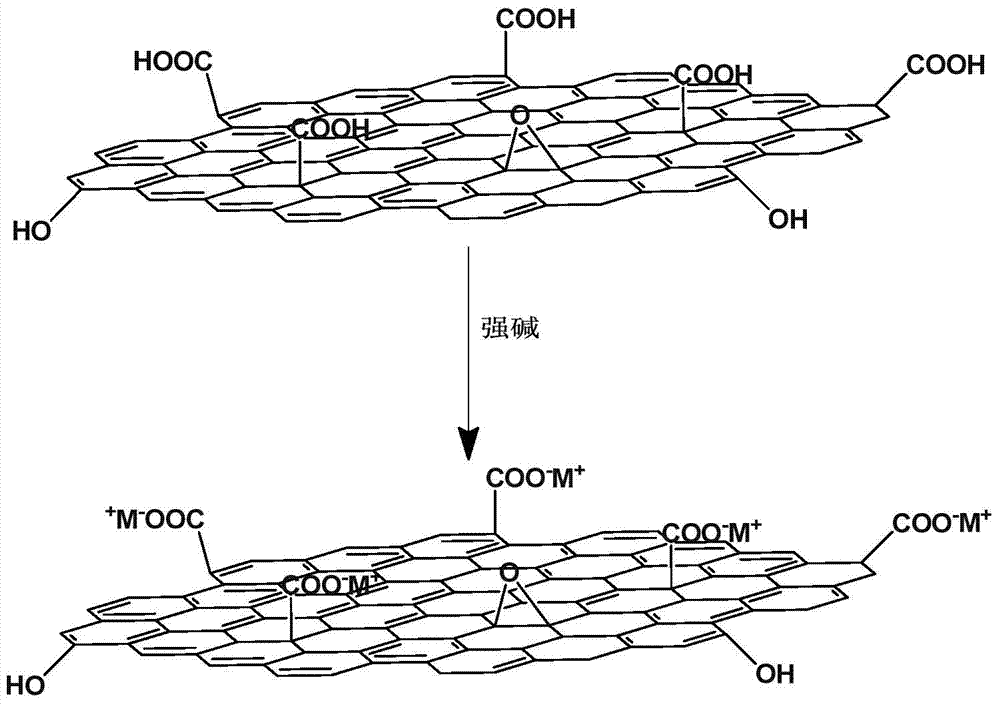

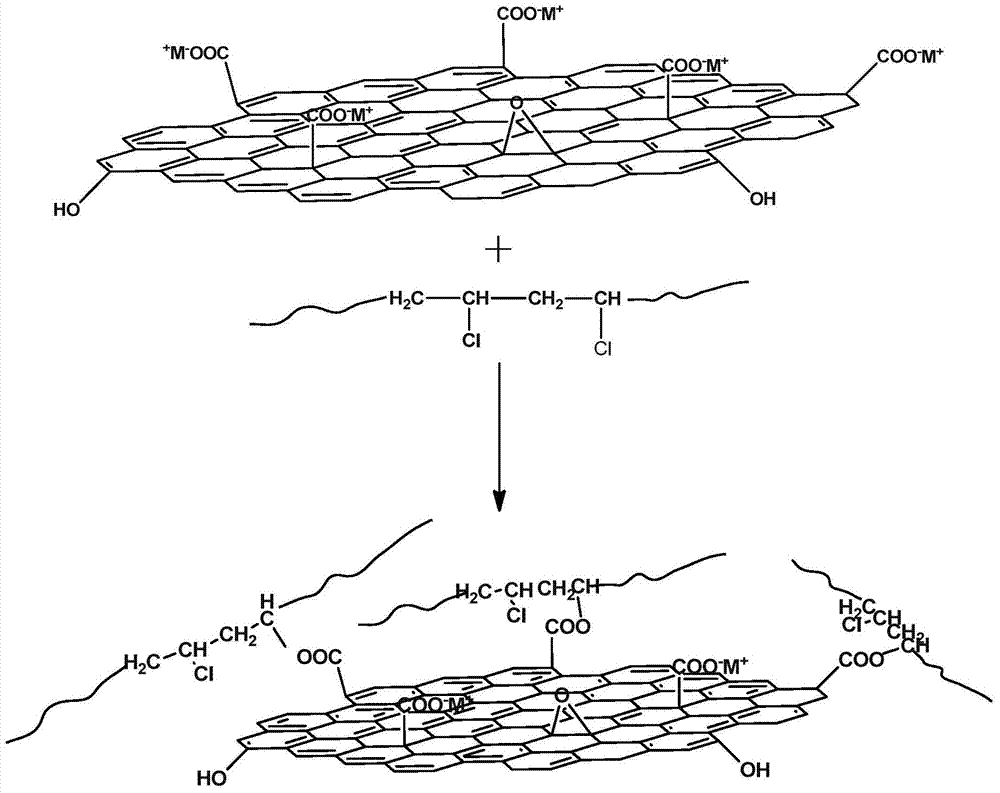

[0031] a. Preparation of the main stabilizer: react graphene oxide with excess sodium hydroxide in water to obtain graphene oxide sodium. After the reaction solution is filtered through a semi-permeable membrane once, it is centrifuged at 3000 rpm, and the supernatant is discarded. , the lower layer was precipitated and dried to obtain solid sodium graphene oxide; respectively weighed 30 parts of graphene oxide sodium, 30 parts of calcium stearate and 40 parts of zinc stearate in parts by weight, and mixed uniformly to obtain the main stabilizer;

[0032] B, the compounding of auxiliary stabilizer: take by weight respectively 55 parts of main stabilizers that step a makes, 20 parts of stearyl benzoylmethane, 20 parts of epoxy sunflower oil, 2 parts of ultrafine zeolite, 1 part of hydrotalcite, 1 part of oxidized polyethylene wax and 1 part of glycerol monooleate are mixed thoroughly to obtain a PVC environment-friendly composite stabilizer based on graphene oxide salt.

[0033...

Embodiment 2

[0035] a, preparation of main stabilizer: take 35 parts of graphene oxide, 45 parts of potassium hydroxide and 20 parts of calcium hydroxide respectively by weight, mix the three in water and make graphene oxide salt, and then react Add 35 parts of stearic acid in the liquid, neutralize the unreacted alkali to generate metal soap salt, obtain the compound of graphene oxide salt and metal soap salt, which is the main stabilizer;

[0036] B, compounding of auxiliary stabilizers: take by weight respectively 60 parts of main stabilizers, 10 parts of stearoylbenzoylmethane, 5 parts of isovalerylbenzoylmethane, epoxy large 10 parts of soybean oil, 5 parts of ultrafine zeolite, 5 parts of hydrotalcite, 2 parts of oxidized polyethylene wax and 3 parts of glycerol monooleate, and fully mixed to obtain a PVC environment-friendly composite stabilizer based on graphene oxide salt.

[0037] After mixing the PVC environment-friendly composite stabilizer prepared in this example with the PVC...

Embodiment 3

[0039]a. Preparation of the main stabilizer: react graphene oxide with excess sodium hydroxide in water to obtain graphene oxide sodium. After the reaction solution is filtered through a semi-permeable membrane once, it is centrifuged at 3000 rpm, and the supernatant is discarded. , the lower layer was precipitated and dried to obtain solid sodium graphene oxide; graphene oxide was reacted with excess potassium hydroxide in water to obtain graphene oxide potassium, and the reaction solution was filtered through a semi-permeable membrane once, then centrifugally settled at 3000 rpm, discarded The supernatant was removed, and the lower layer was precipitated and dried to obtain solid graphene oxide potassium; 30 parts by weight of graphene oxide sodium, 20 parts of graphene oxide potassium, 20 parts of calcium stearate and 30 parts of zinc stearate were weighed respectively , mixed evenly to obtain the main stabilizer;

[0040] B, the compounding of auxiliary stabilizer: take by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com