Preparation method of graphene strengthened nickel-aluminum alloy based composite

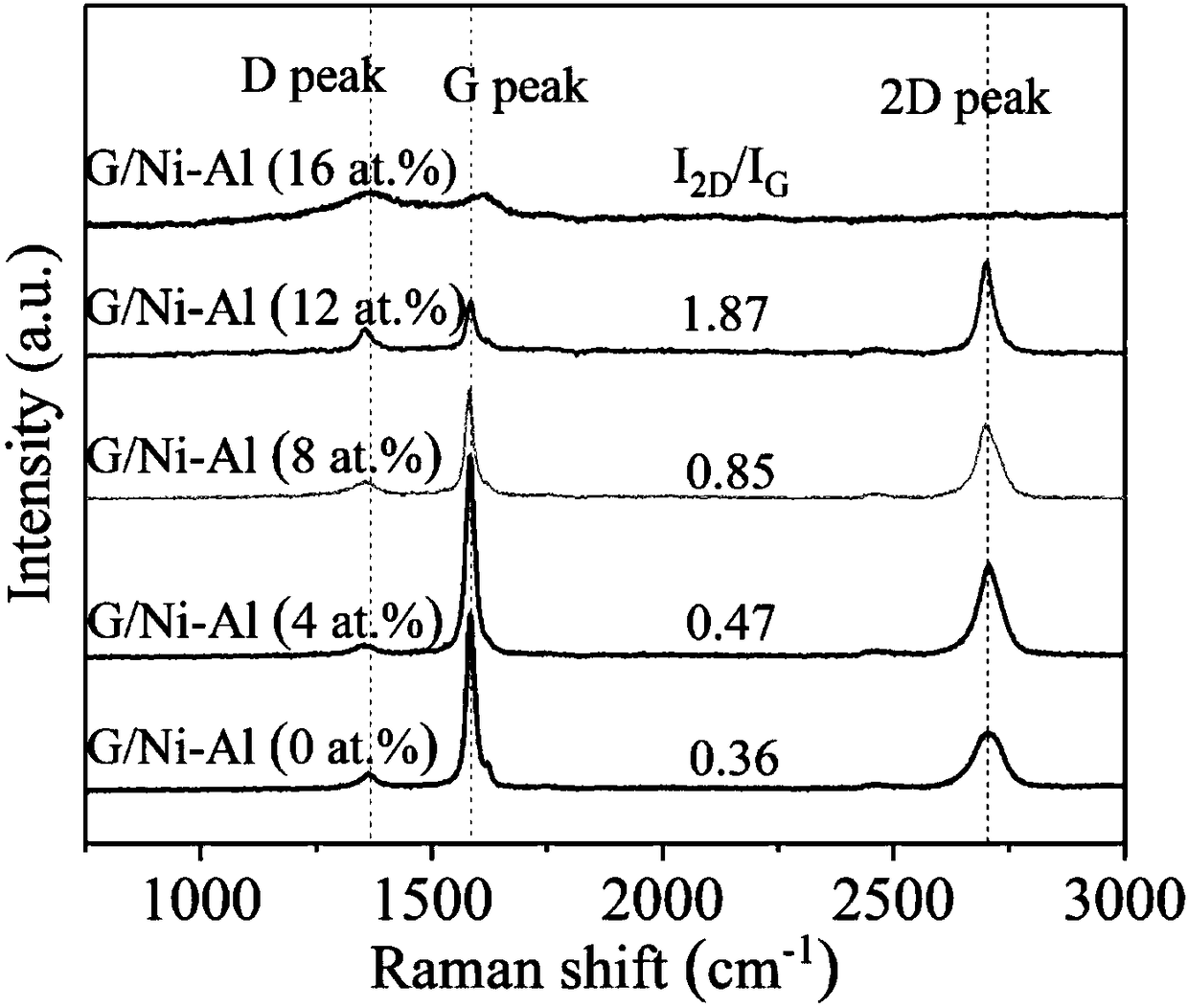

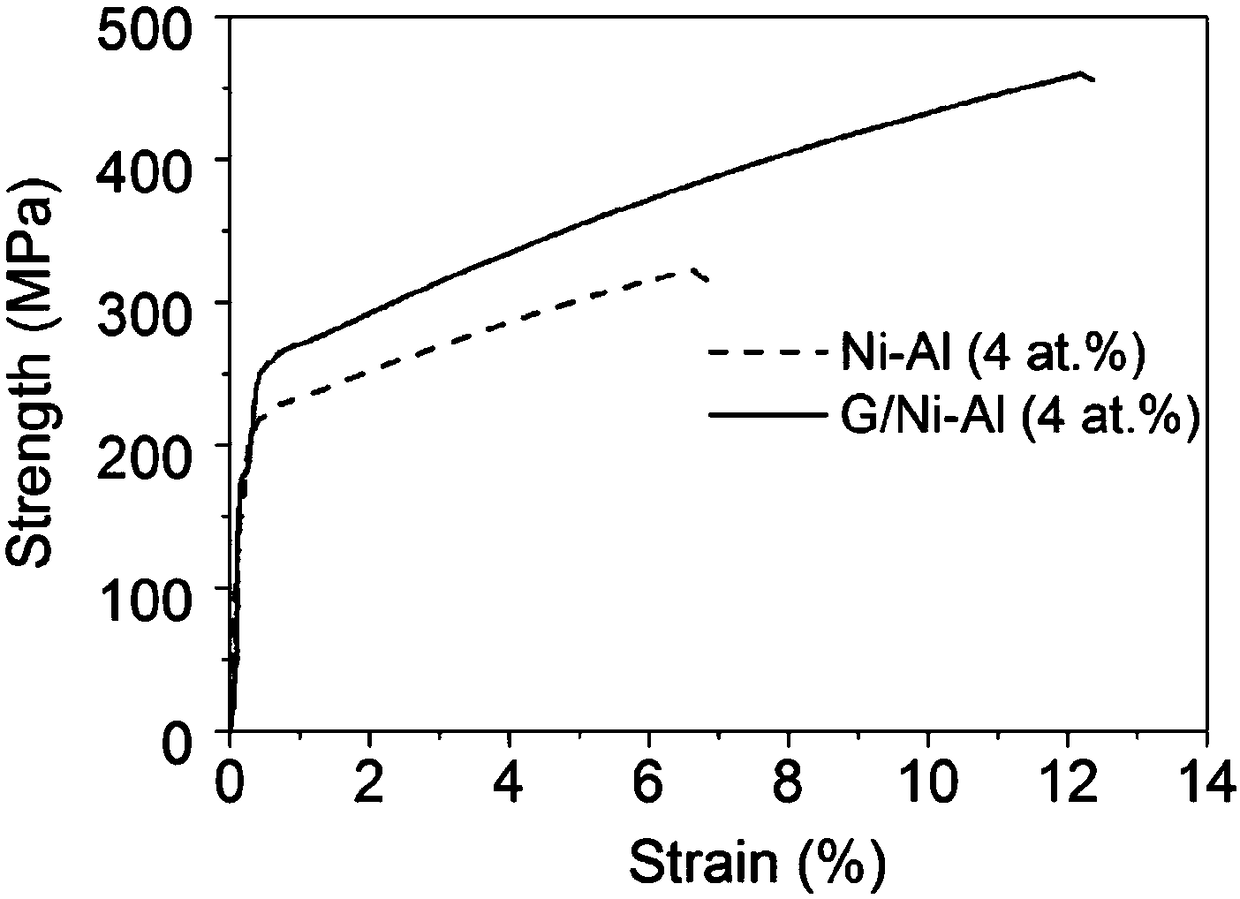

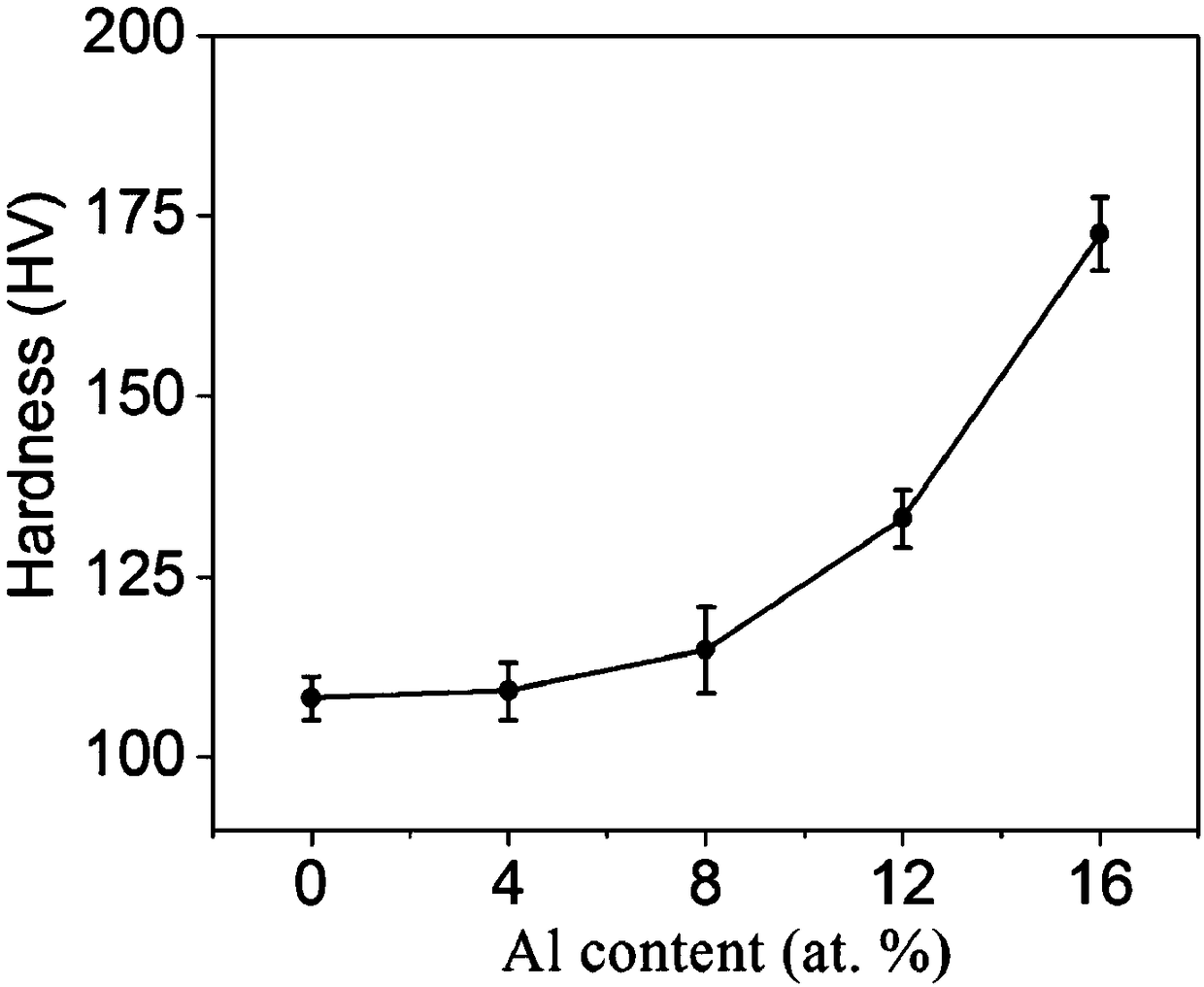

A nickel-aluminum alloy and composite material technology is applied in the field of graphene-enhanced nickel-aluminum alloy-based composite materials, which can solve the problems of graphene being difficult to disperse, and achieve the effects of good binding force, simple preparation process and few defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The steps for in-situ preparation of graphene-reinforced nickel-aluminum alloy matrix composites with a controllable number of layers are as follows:

[0031] (1) Dissolve 240mg of sucrose in 150mL of deionized water, then add 10g of metal nickel powder, then heat and stir at 120°C until the water evaporates completely, and then dry in an oven at 50°C to obtain sucrose packets Coated nickel powder;

[0032] (2) After uniformly mixing sucrose-coated nickel powder and 0.19g (4at.%) aluminum powder, transfer it to a mold for cold-press forming to obtain a green body; wherein, the pressure of cold-press forming is 320MPa, and the holding time 10min;

[0033] (3) Put the green body into the vacuum sintering furnace. When the pressure in the furnace is lower than 0.1Pa, fill in hydrogen and argon until the pressure in the furnace reaches 900Pa, then heat the vacuum sintering furnace to 1150°C and keep it for 1 hour. Immediately transfer the sample to the low-temperature zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com