Microwave and far infrared vulcanization method and equipment

A microwave vulcanization and far-infrared technology, applied in the field of microwave and far-infrared vulcanization, can solve the problems of low vulcanization work efficiency and easy combustion of brown fiber materials, and achieve the effect of shortening vulcanization time, short time and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

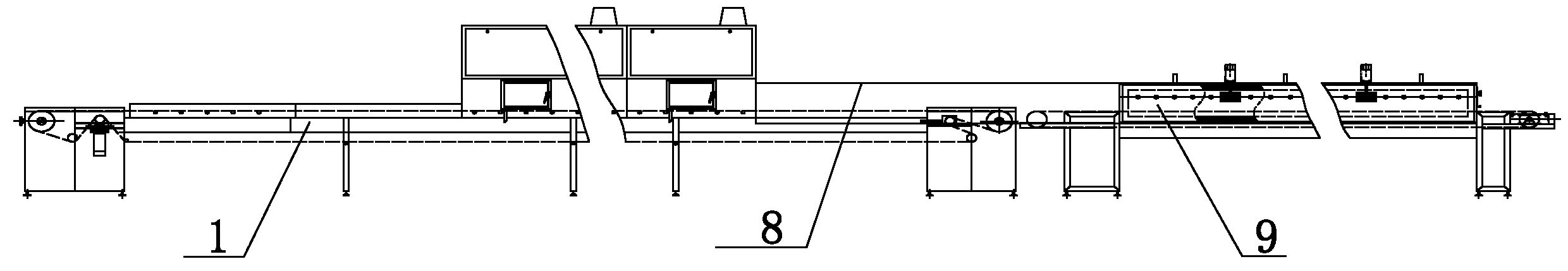

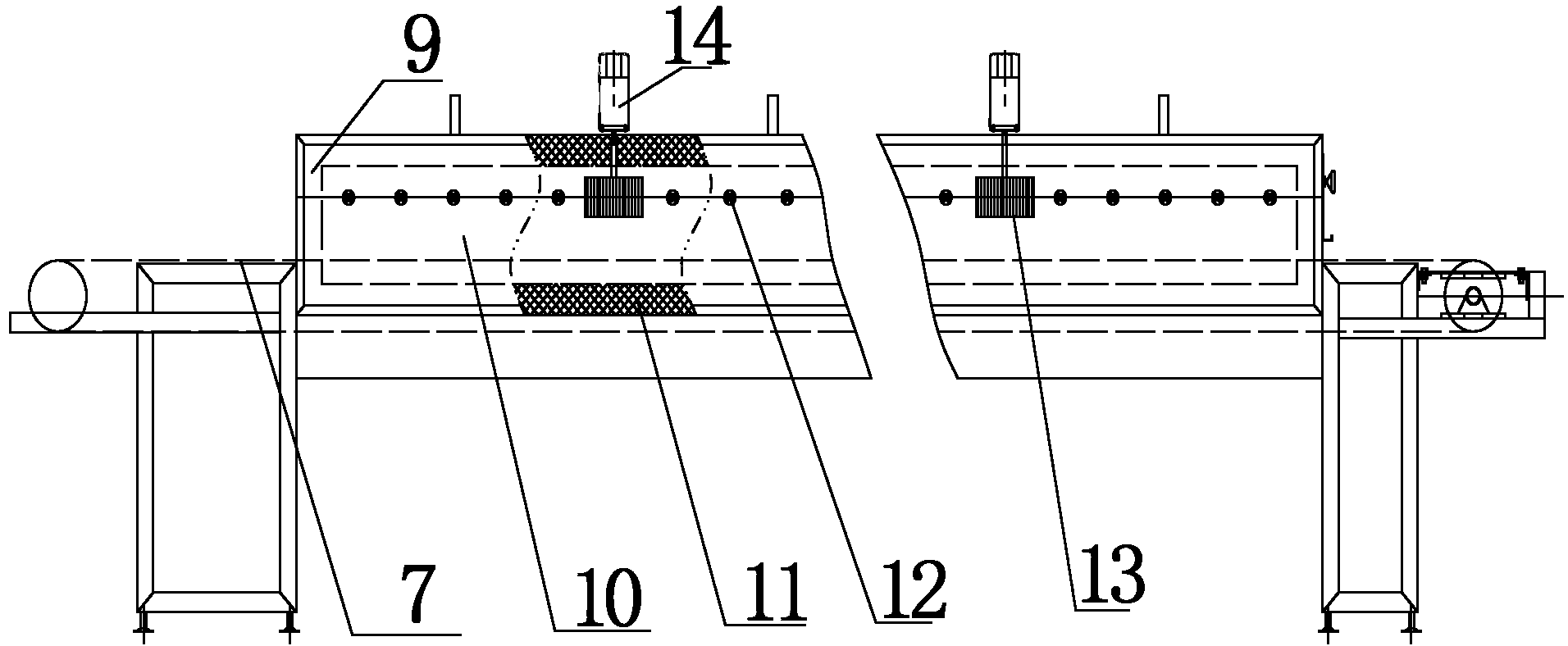

[0022] Embodiment 1 of the present invention: as attached figure 1 As shown, a microwave and far-infrared vulcanization equipment includes a microwave vulcanizer 1, a far-infrared vulcanizer 9 is installed behind the microwave vulcanizer 1, and a conveyor belt 7 is installed on the microwave vulcanizer 1 and the far-infrared vulcanizer 9.

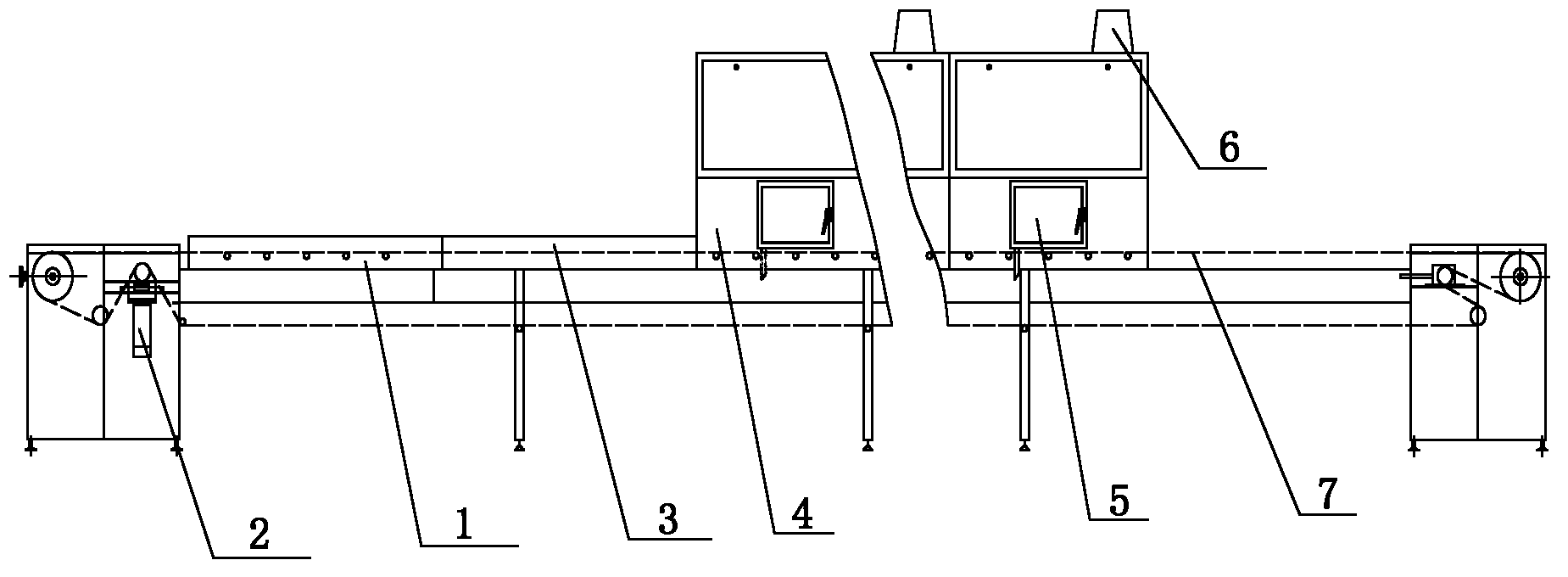

[0023] And this microwave curing machine 1, as attached figure 2 As shown, there are several interconnected microwave vulcanization boxes 4 installed on the microwave vulcanizer 1. There is a microwave generator inside the microwave vulcanization box 4, which can heat the inside of the microwave vulcanization box 4. In order to facilitate the observation of the working process and prevent the vulcanization heating process The material in the medium will burn, and an observation window 5 is also provided on the microwave vulcanization box 4. A moisture exhaust cover 6 is installed on the top of the microwave vulcanization box 4, driven by a...

Embodiment 2

[0031] Example 2: When the pillow enters the microwave vulcanization box 4 through the conveyor belt 7 for the first vulcanization, the temperature of the microwave vulcanization box 4 should be 80-90°C, and the entire first vulcanization time is 9-12 minutes. When the pillow comes out from the microwave vulcanization box 4 and enters the far-infrared vulcanization box 10 for the second vulcanization: the temperature in the far-infrared vulcanization box 10 should be: 105-115°C, and the entire second vulcanization time is: 20-25min.

[0032] During the vulcanization process, if the temperature in the microwave vulcanization box 4 exceeds 105°C and lasts for 2 minutes, the hidden dangers can be eliminated by temporarily shutting down the microwave vulcanizer 1, increasing the running speed of the conveyor belt 7, or reversing and exiting the conveyor belt 7. During the operation of the microwave vulcanizer 1, it is strictly forbidden to open the microwave vulcanization box 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com