Processing method for artificial board hot-press hot pressing board plane

A technology of surface processing and process method, which is applied in the direction of veneer press, plywood press, manufacturing tools, etc., can solve the problems that the surface roughness and flatness cannot be guaranteed, and the surface roughness or flatness cannot meet the requirements, etc. The clamp deformation factor is reduced, the milling quality is improved, and the rigidity is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

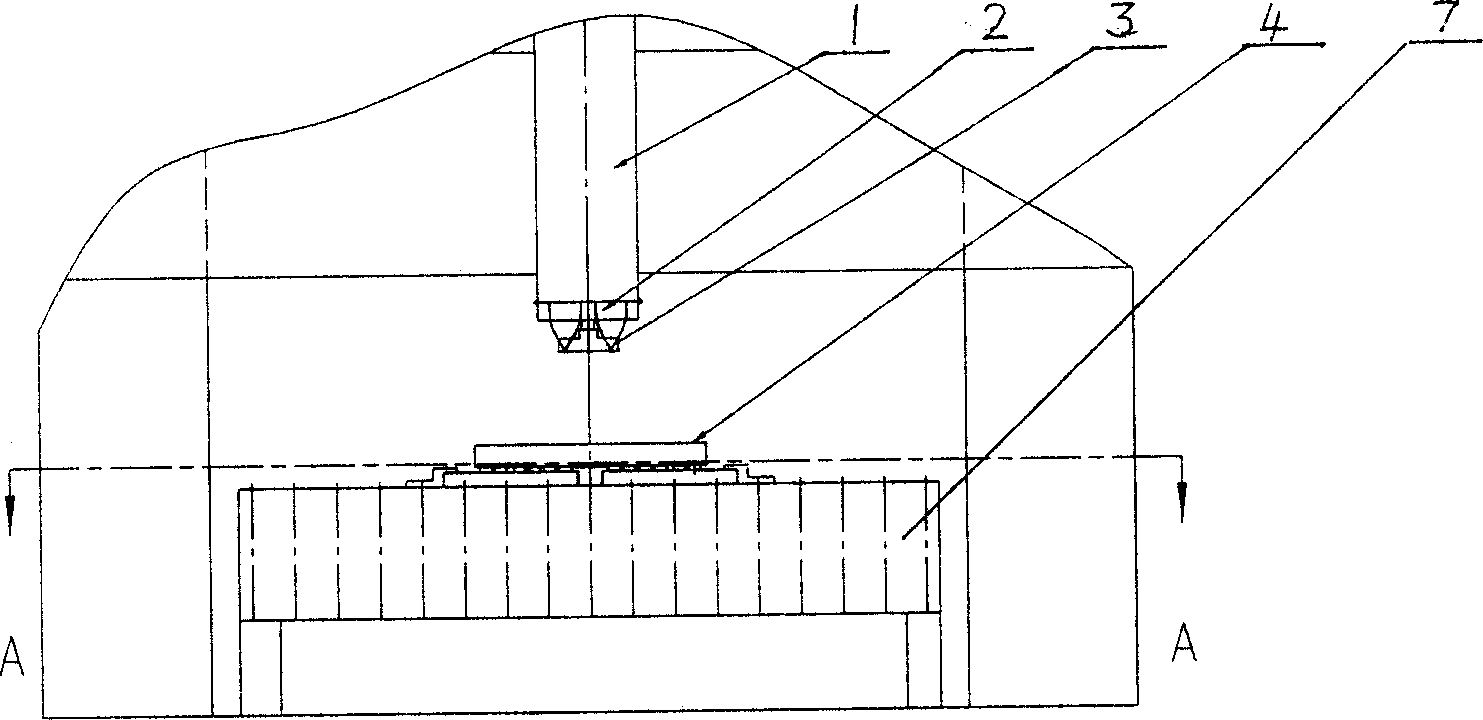

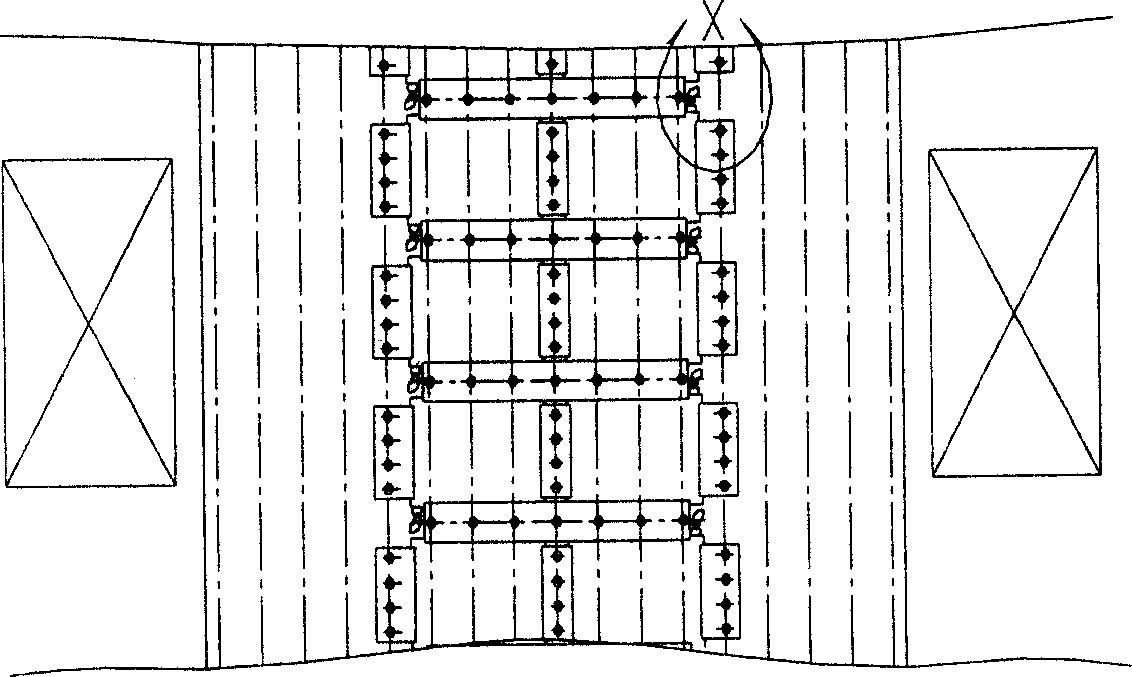

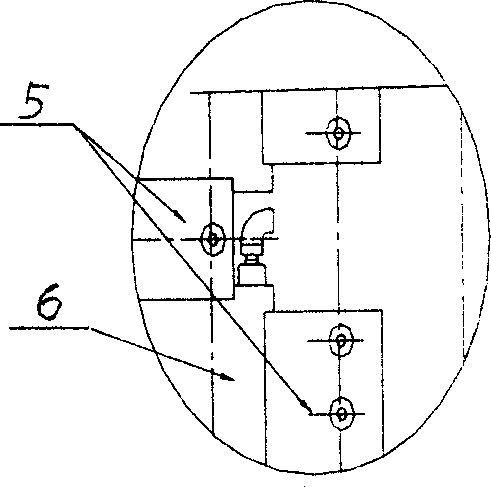

[0018] attached figure 1 , 2 And 3 is an embodiment of the present invention, is that the production width is 1380mm wood-based panel flat pressing type novel hot press machine hot press plate plane processing. The size of the workpiece hot-pressing plate 4 is 100*1380*6850mm, and the material is a special custom-made pretreatment die steel (close to NAK80), with a hardness of about HRC40. 1. The CNC gantry boring and milling machine is imported from Jinan No. 2 Machine Tool Factory (model XMK2136*12). The accuracy indicators of the machine tool must meet the acceptance standards of JB6086-92. Adjust the spindle of the main milling head 1 of the boring and milling machine so that the spindle taper hole axis is Vertical state, fine-tuning key items such as spindle end jump to improve the measurement accuracy, and the runout detected by the rotary angle measuring stick at the extension of 300mm is less than 0.008mm. 2. Face milling cutter head 3 adopts SECO eight-sided adjusta...

Embodiment 2

[0020] Another embodiment of the present invention is that the production width is 2650mm wood-based panel flat pressing type new type hot press hot press plate plane processing. The size of the workpiece hot-pressing plate 4 is 100*2650*6850mm, and the material is special custom-made pretreatment die steel (close to NAK80), with a hardness of about HRC40. Face milling cutter head 3 adopts SECO eight-sided edge adjustable fine-tooth face milling cutter φ315mm diameter 40 teeth cutter head, adopts 6 pieces of wiper blades and 34 pieces of cutting edge blades to be arranged and clamped in a staggered and symmetrical manner, and is carried out by a high-precision tool setting instrument Pre-adjustment, adjust the axial height of 34 cutting edges to be the same, the error is less than 0.01mm, adjust the axial height of the 6 wiper blades to be the same, the error is less than 0.001mm, and the wiper edge is 0.03mm higher than the cutting edge. Its technological parameter and numeri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com