Processing method for reinforcing cage for pre-stressed concrete hollow square pipe pile

A technology of hollow square pipe and processing method, which is applied in the direction of strengthening molding, etc., can solve the problems of low processing efficiency, influence, and influence on the quality of prestressed concrete hollow square pipe piles, and achieve the effect of improving production efficiency and stabilizing welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

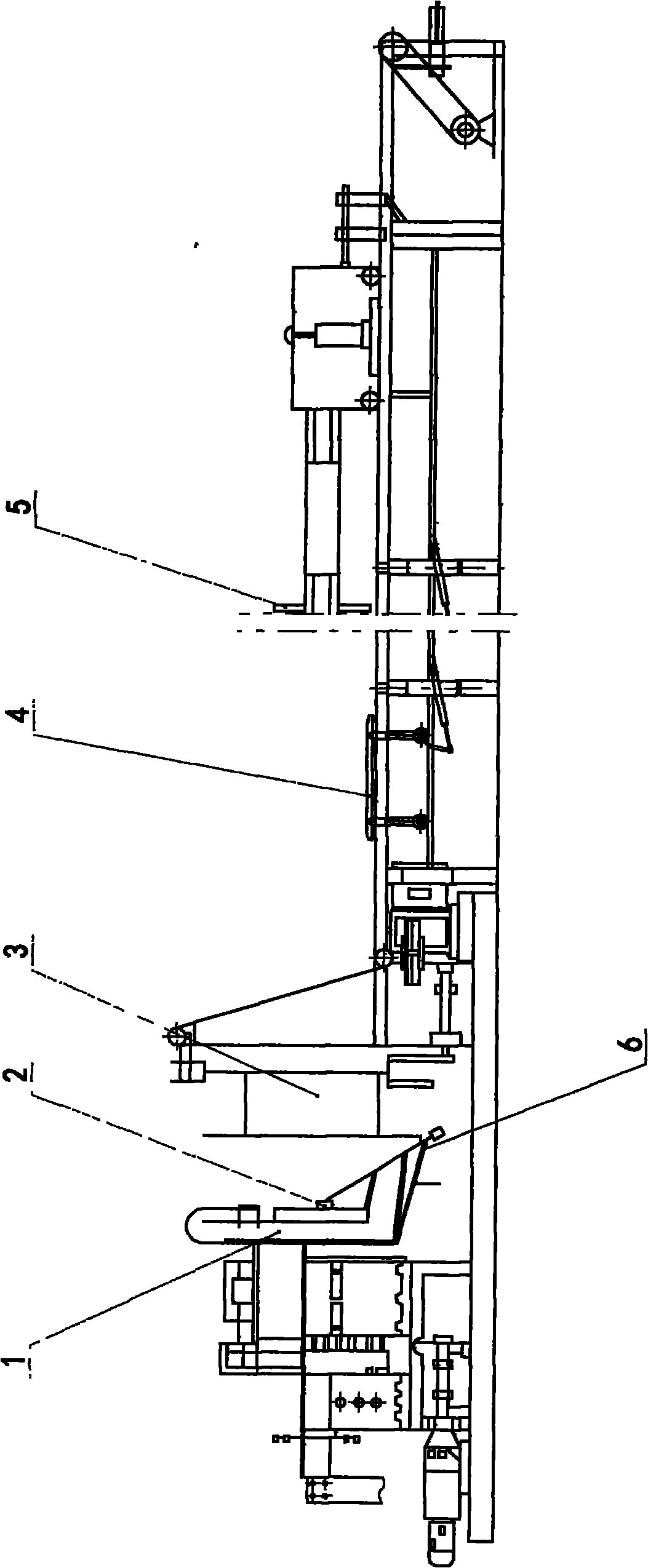

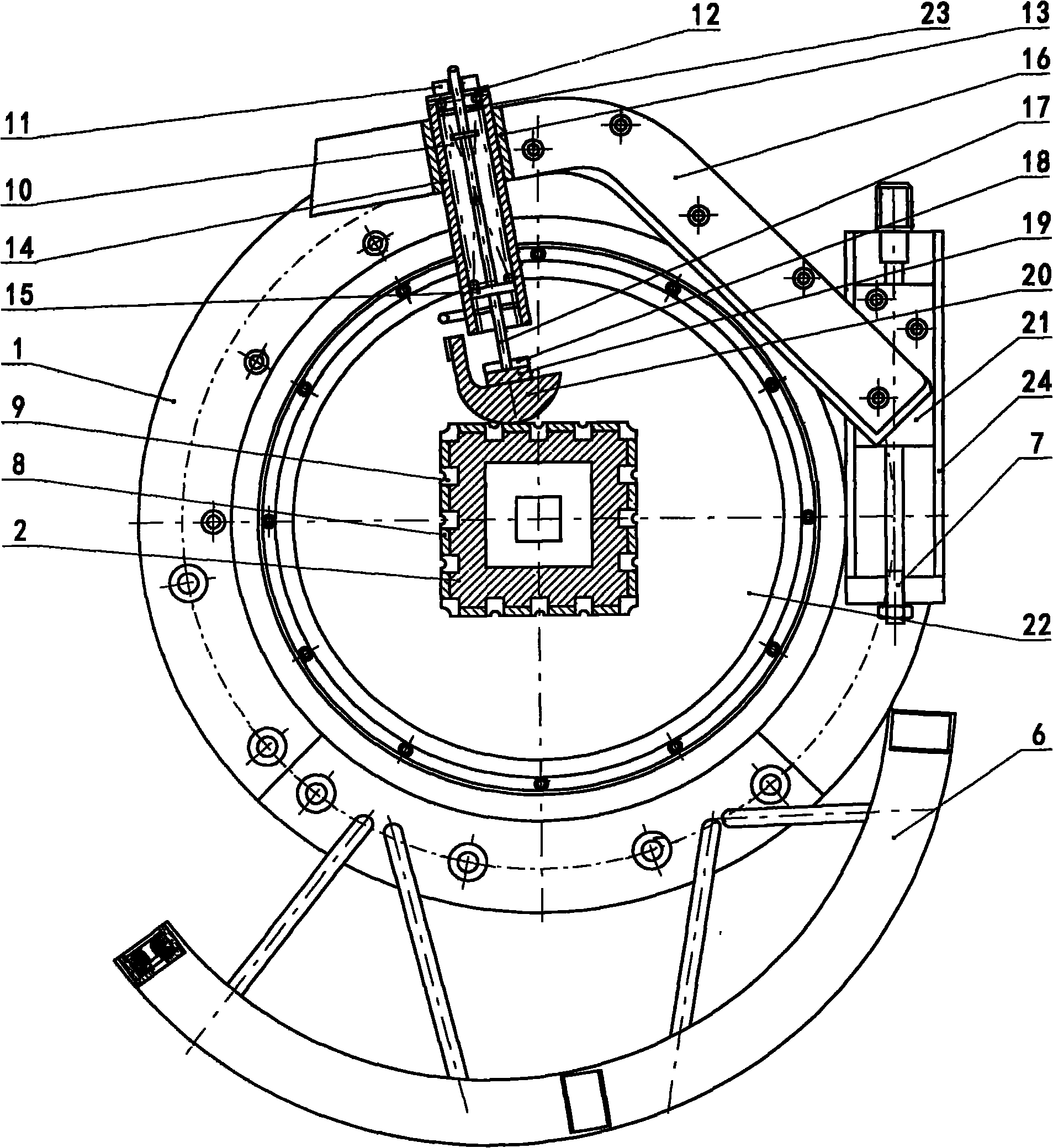

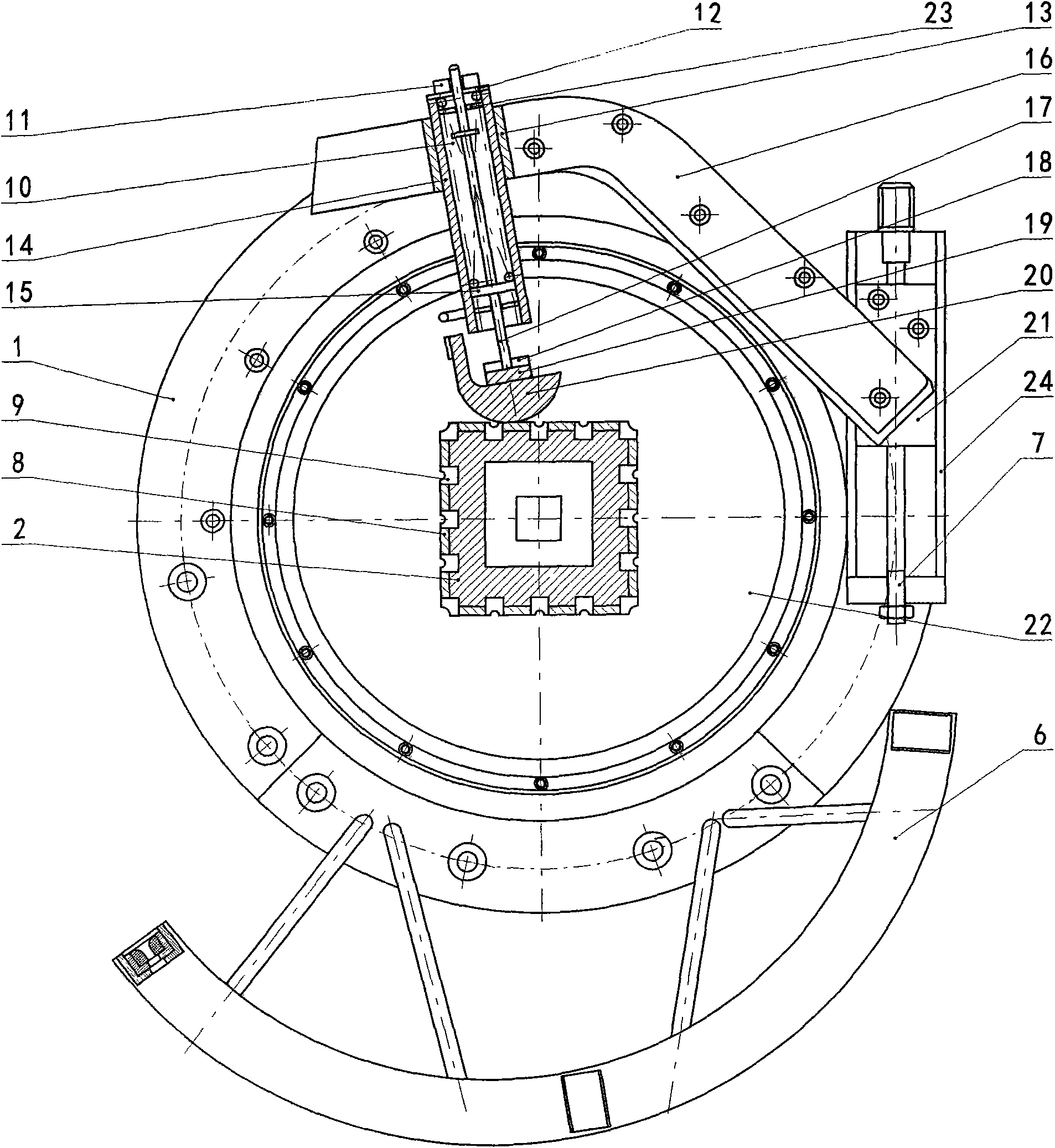

[0027] The structure of the roll welding machine for the reinforcement cage of the prestressed concrete hollow square pipe pile is: a square fixed electrode 2, an elastic movable electrode, a longitudinal reinforcement traction plate 5, a longitudinal reinforcement feeding mechanism, a ring reinforcement disk 3, and a spiral ring reinforcement winding mechanism 6. Reinforcement cage transmission mechanism 4, the four corners and four planes of the square fixed electrode 2 are provided with several rib grooves 9 along the axial direction, the square fixed electrode 2 is fixed on the bracket 22, and the elastic movable electrode is movably connected to the electrode wheel 1, the spiral ring tendon winding mechanism 6 is fixed on the electrode wheel 1, the elastic movable electrode includes an electrode body 20 and a seat body 14 elastically connected with the electrode body 20, an end plate 12 is installed on the upper end of the seat body 14, and the adjustment screw rod 17 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com