Shale hydraulic fracture propagation prediction method

A fracture propagation and prediction method technology, which is applied in the field of shale hydraulic fracture propagation prediction, can solve the problems of prediction error and low accuracy rate, and achieve the effect of high accuracy, accuracy assurance, accuracy rate and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In the shale hydraulic fracture propagation prediction method, in the operation process, the normal stress and tangential stress of oblique fractures under the compressive stress field are firstly calculated.

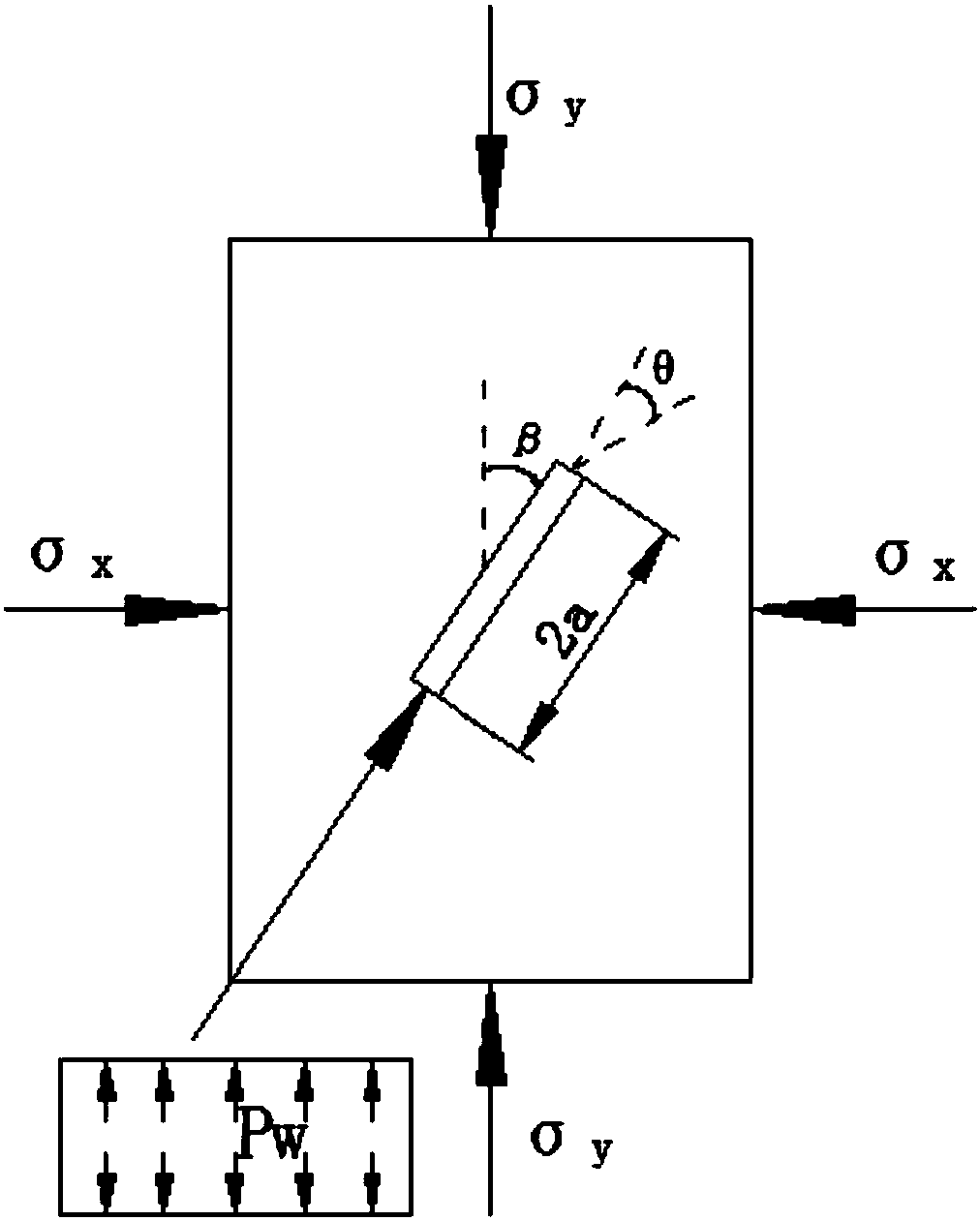

[0067] The stress of inclined cracks under the action of compressive stress field is as follows: figure 1 As shown, according to the pseudo-force method and superposition principle, the normal stress and tangential stress on the fracture surface are obtained as Equation 1:

[0068] In the formula, P is the normal pseudo force acting on the fracture surface, Q is the tangential pseudo force acting on the fracture surface, β is the angle between the fracture and the vertical compressive stress direction, σ x is the horizontal pressure, σ y is the vertical pressure.

[0069] After obtaining the normal pseudo-force of the fracture surface, the effect of water pressure Pw on the fracture surface is considered, as shown in figure 1 As shown, the normal stress of t...

Embodiment 2

[0103] This example provides the verification of the influence of natural fractures on the propagation direction of shale hydraulic fractures.

[0104] Using the prediction method process in Example 1, and based on the analysis model of bedding on the propagation direction of shale hydraulic fractures, set natural fractures at a distance of 0.5m from the front of the perforation. Natural fractures are replaced by weak unit areas, with a length of 1m and a thickness of 0.05m. The elastic modulus of natural fractures is 1 / 10 of the shale matrix, the tensile strength and critical energy release rate are 1 / 100 of the shale matrix, and the rest Poisson's ratio, permeability coefficient, fracturing fluid viscosity, fluid loss coefficient and shale matrix are the same. There is a certain included angle β between the maximum principal stress directions, which are 45°, 60°, and 75° respectively. The rock mass and numerical related parameters are shown in Table 2. Under the same groun...

Embodiment 3

[0110] This example provides verification of the influence of in-situ stress difference on the propagation direction of shale hydraulic fractures.

[0111] According to the model in Example 2, when the maximum principal stresses are 20MPa, 25MPa, and 30MPa, the horizontal ground stress differences are 0, 5, and 10MPa, respectively. The intersection angle of hydraulic fractures and natural fractures / angle change of hydraulic fractures crossing natural fractures can be obtained, and the results are shown in Table 3.

[0112] According to Table 3, the smaller the horizontal stress difference, the easier it is for the hydraulic fracture to deviate from the maximum principal stress direction and tend to be perpendicular to the natural fracture before penetrating into the natural fracture, and the easier it is for the hydraulic fracture to be parallel to the natural fracture inside the natural fracture. Crack direction expansion. And the larger the horizontal stress difference is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com