Self-adaptive placing angle pressing device and pressing method thereof

A pressing device and self-adaptive technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of inconsistency in the pressing direction of the force direction, inability to set vertically, and affect the assembly quality, so as to improve the assembly quality and efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

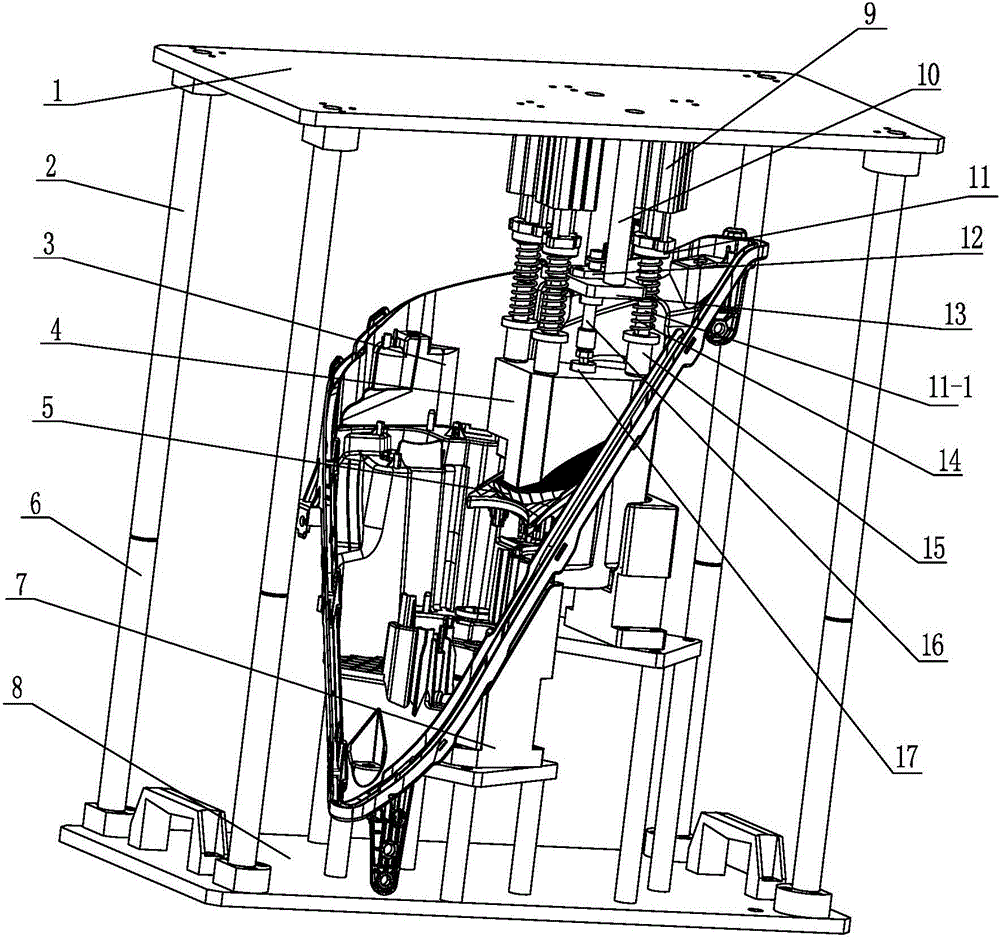

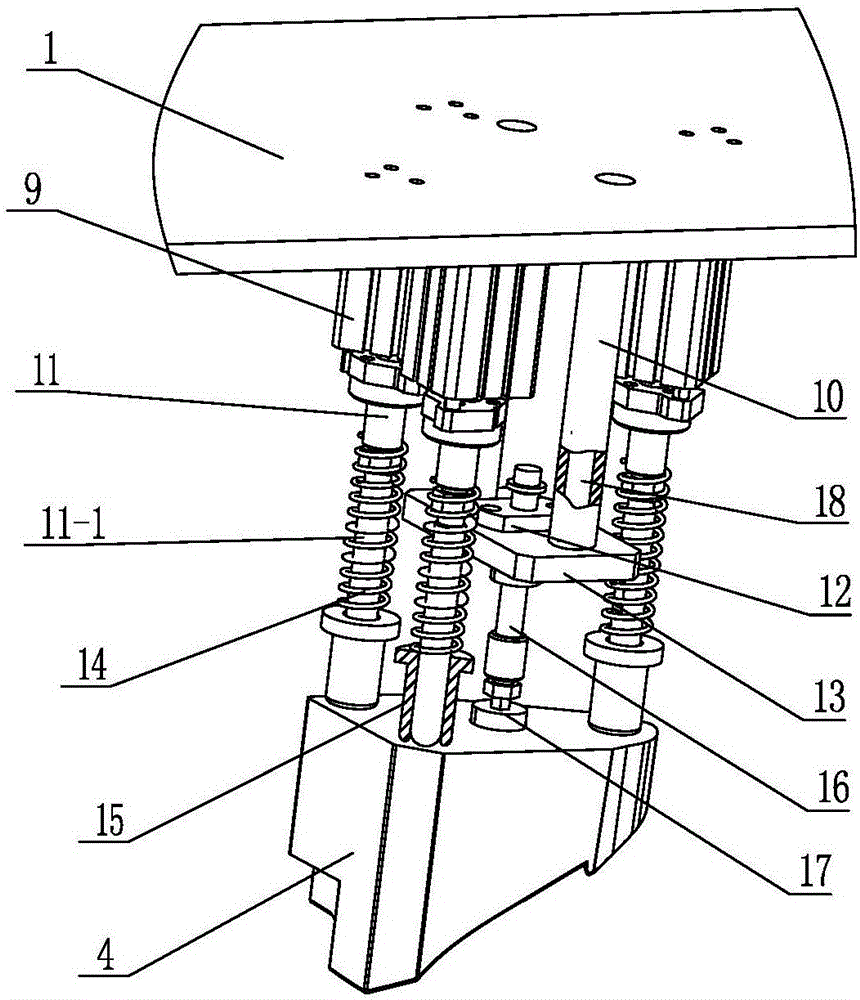

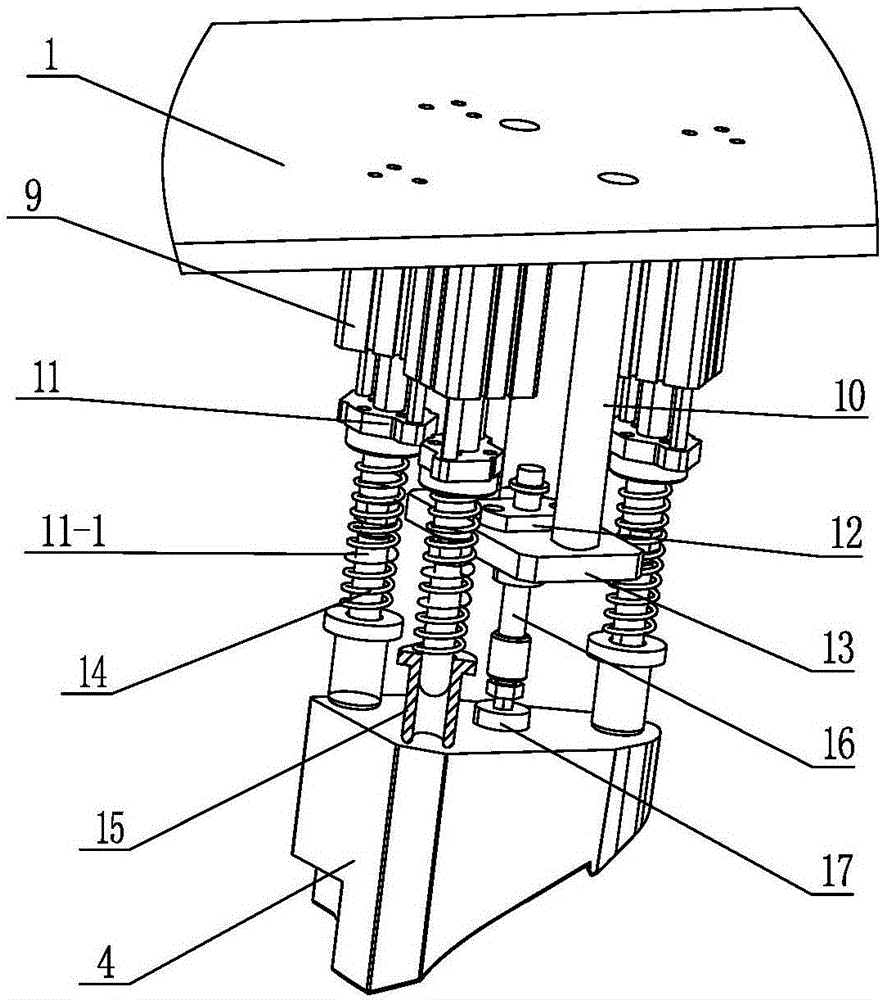

[0024] See Figure 1~3 As shown, the self-adaptive placement angle pressing device of the present invention includes a mold 7 installed on the bottom plate 8 for supporting and positioning the lower workpiece, and a pressing machine connected to the upper connecting plate 1 to press the workpiece and have a slope at the bottom. Block 4, the slope at the bottom of the briquetting block 4 is an inclined plane or / and an inclined curved surface, the bottom plate 8 is installed on the workbench of the press, and the upper connecting plate 1 is connected to the main cylinder or main oil cylinder on the press. By operating the press The switch on the main cylinder or the main oil cylinder drives the upper connecting plate 1 to move upward to open the mold, and the loading and unloading of the workpiece is carried out; and when the main air cylinder or the main oil cylinder drives the upper connecting plate 1 to move down and close the mold, it can be carried out. Workpiece press-fit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com