Construction method for carrying large box girder by tire type portal jib crane

A construction method and tire-type technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., to achieve good safety, mature technology, and reasonable load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

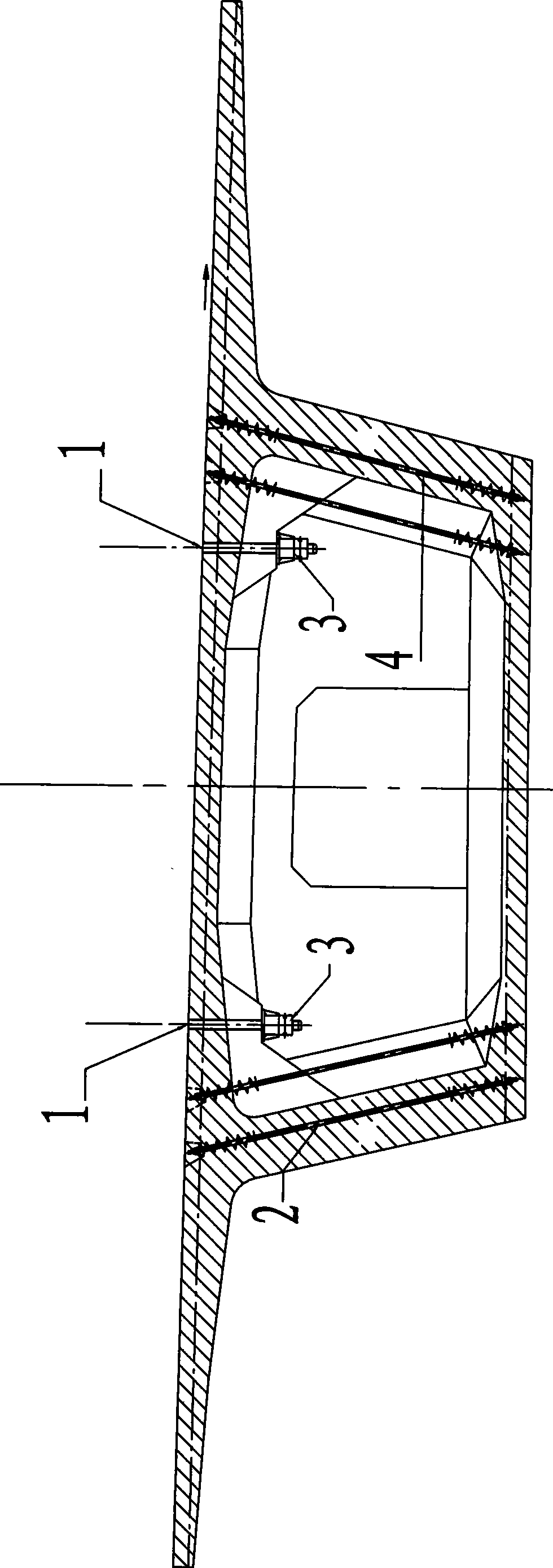

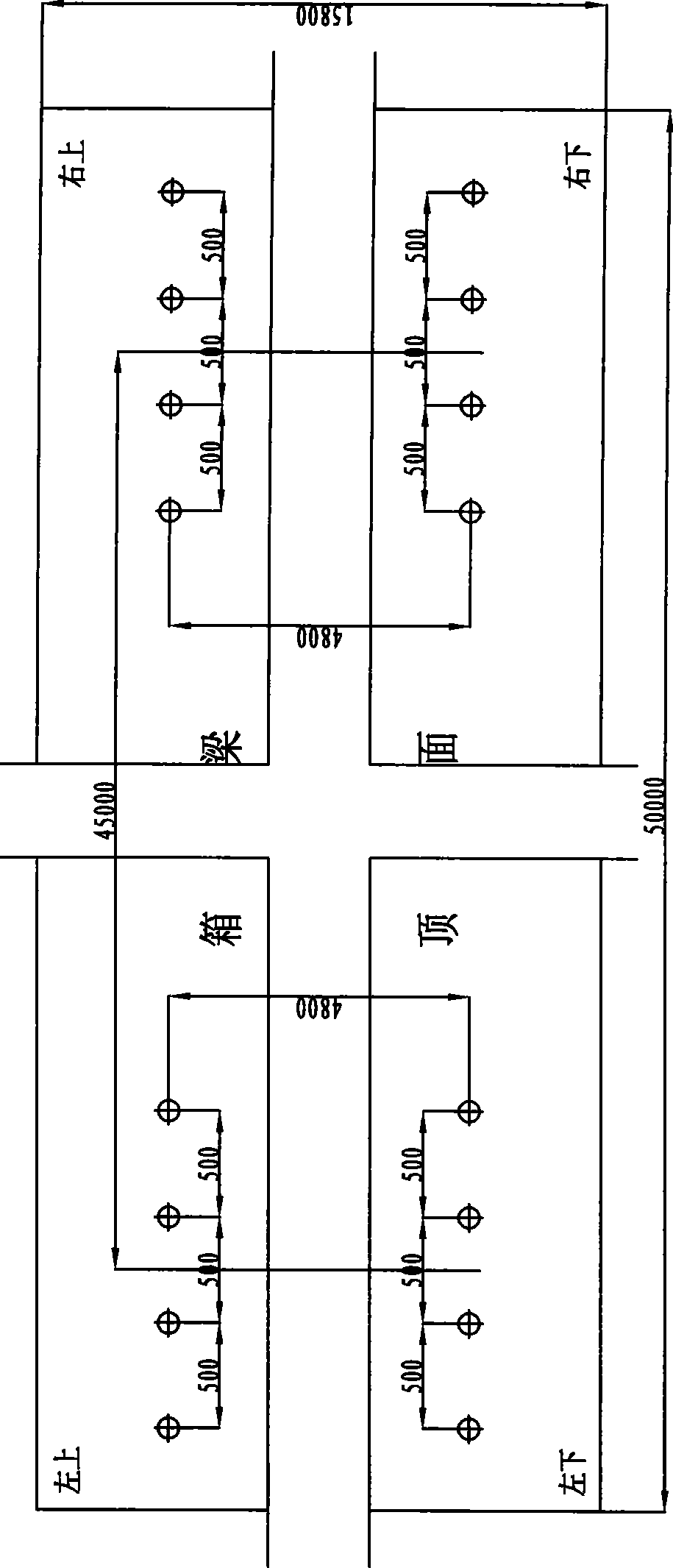

[0027] The construction method of the present invention tire-type door crane carrying box girder see figure 1 , figure 2 , image 3 , Figure 4 As shown, it is necessary to reserve hoisting holes when the box girder is prefabricated. After comparing various lifting methods such as the bottom joist / sling method, the roof / web / bottom perforated boom method, and the top / web / bottom pre-embedded lifting ring method, the roof perforated boom method was finally selected. This method has the advantages of There are many similar construction experiences at home and abroad, mature and reliable schemes, safe operation, easy disassembly and assembly, high efficiency, no influence on the prefabricated model of the box girder, and can effectively reduce the height of the equipment, etc. Roof piercing boom method see figure 1 and figure 2 .

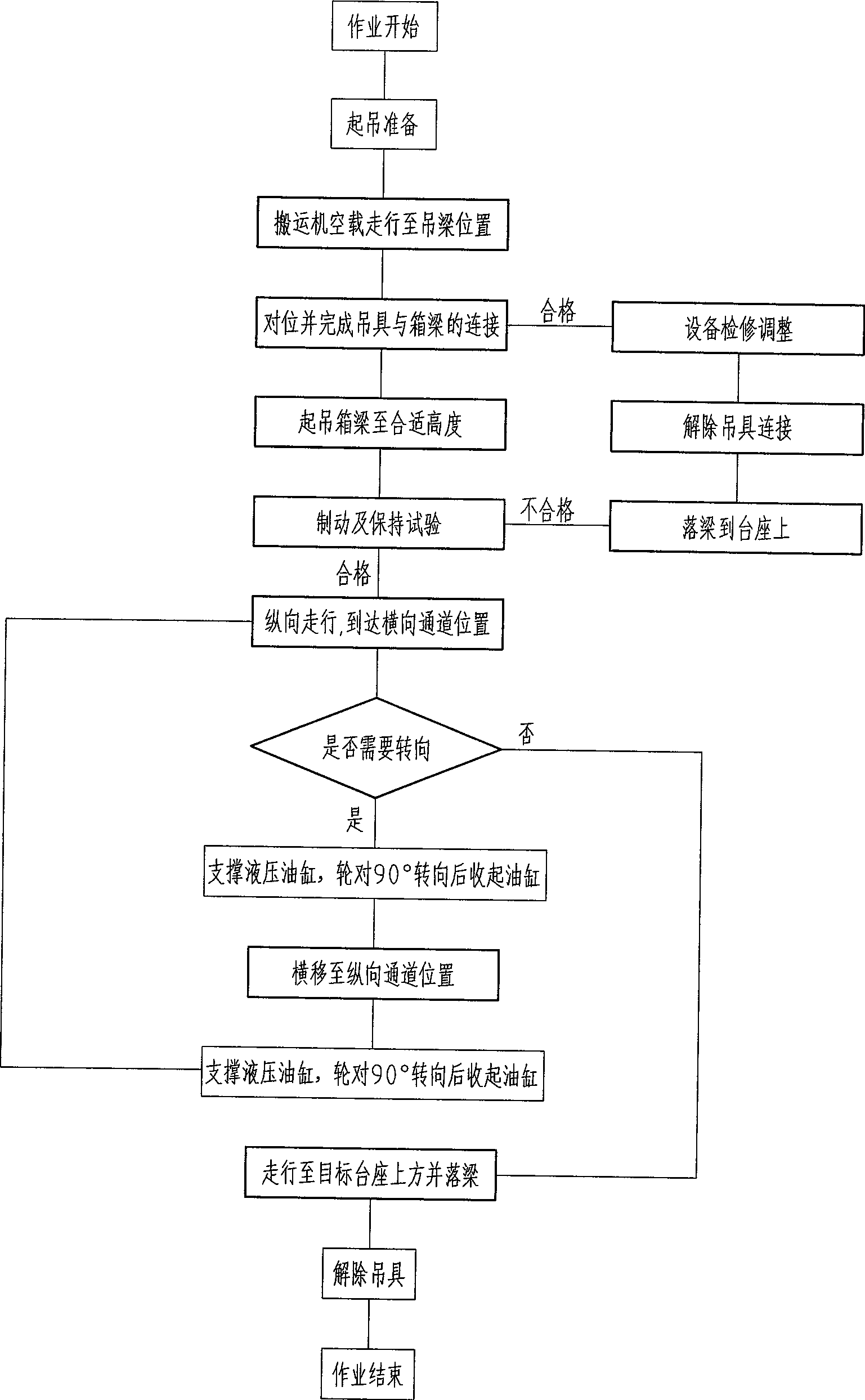

[0028] Concrete construction method of the present invention is following steps (see image 3 ):

[0029] 1. Handling preparation

[0030] (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com