Carbonaceous schist tunnel blasting method and construction method

A carbonaceous schist and tunnel construction technology, applied in blasting, tunneling, earthwork drilling, etc., can solve the problems of high excavation quality, indeterminate exposed area, and no mature method for carbonaceous schist tunnels, so as to improve the excavation efficiency. , the effect of reducing disturbance and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

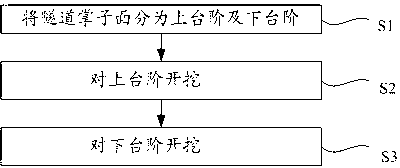

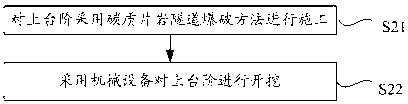

[0036] see figure 1 , which is a preferred embodiment of the present invention aims to provide a carbonaceous schist tunnel excavation method capable of efficiently excavating carbonaceous schist tunnels and reducing damage to surrounding rocks. This method is especially suitable for excavating carbonaceous schist tunnels in V-level surrounding rocks. Excavation, meanwhile, is especially the case where the area of carbonaceous schist accounts for 60% or more of the face of the tunnel face.

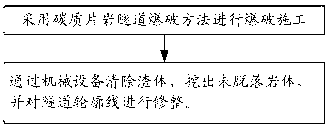

[0037] Such as figure 1 As shown, the carbonaceous schist tunnel construction method provided by the preferred embodiment of the present invention includes: adopting the carbonaceous schist tunnel blasting method for blasting construction; using mechanical equipment to remove slag, dig ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com