Bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock

A technology of zonal rupture and bolt support, which is applied in the direction of earth drilling, installation of bolts, mining equipment, etc., can solve the problems of inapplicability, achieve the effects of improving stability, speeding up construction, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

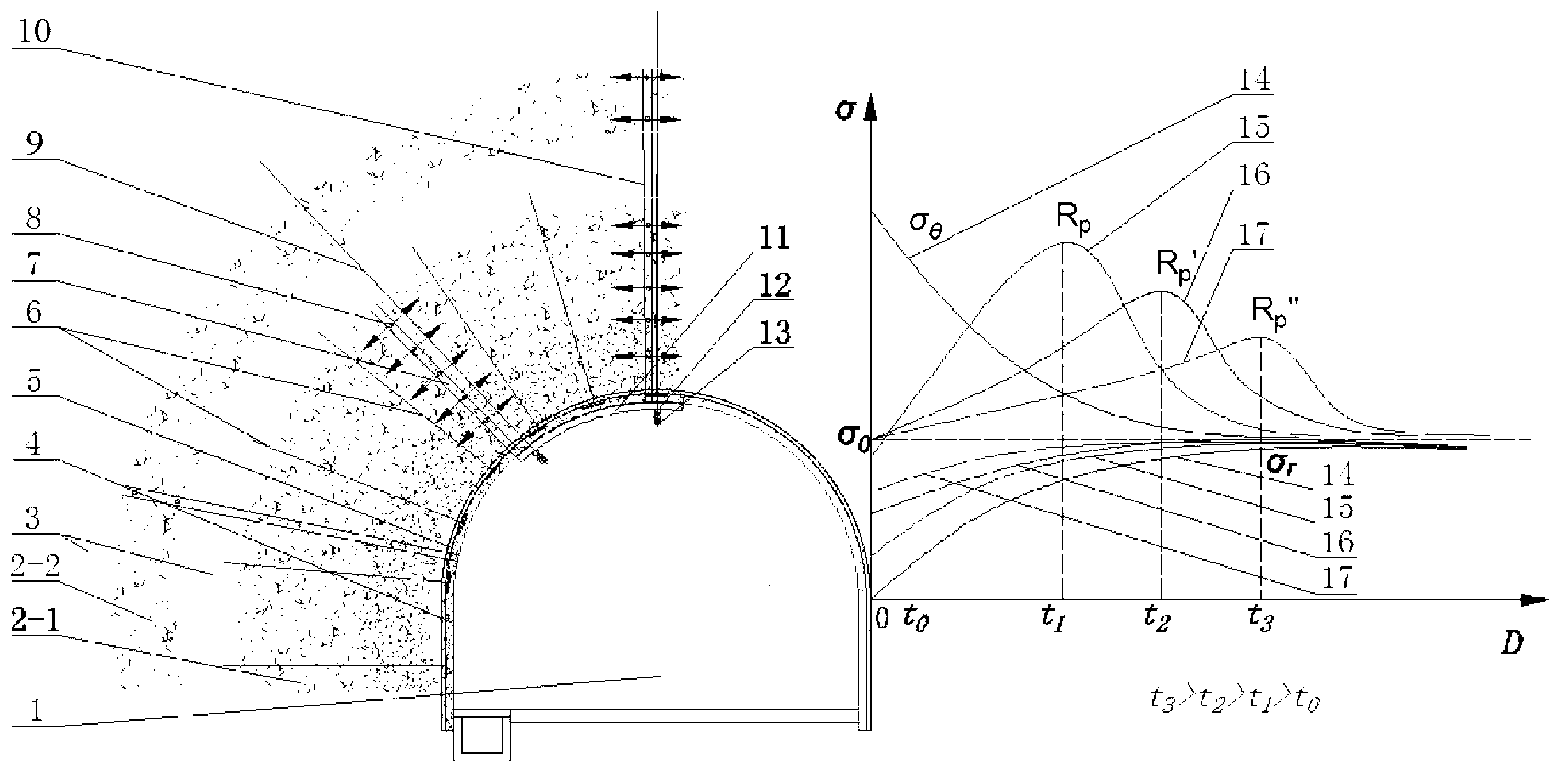

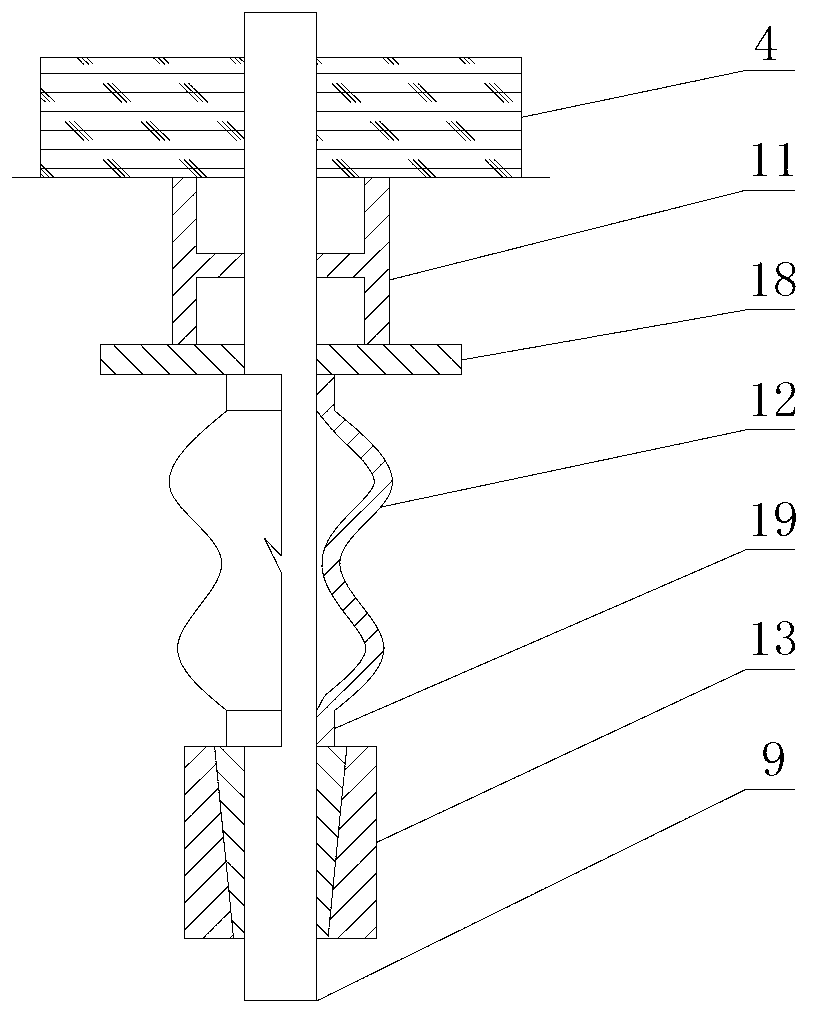

[0025] Now in conjunction with the accompanying drawings and taking a certain mine as an example, the technical scheme of the present invention will be described in detail.

[0026] 1. First, according to figure 1 The bolt-sprayed net support is carried out to improve the stress state of the surrounding rock, to increase the normal restraint, and to strengthen the bolt to prevent cracking. The specific measures are as follows:

[0027] (1) After the excavation of the deep roadway 1 in a certain mine, the radial stress decreased rapidly due to unloading, and the hoop stress increased. The surrounding rock formed on the surface of the surrounding rock was in the initial excavation stress state 14, which was not conducive to the stability of the roadway 1. The anchor shotcrete support shall be carried out as soon as possible to improve the stress state of the surrounding rock. After the excavation, spray concrete 4 with a thickness of 20-30mm to seal the surrounding rock in time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com