Three-anchor coupling supporting method for high stress tunnel break wall rock

A coupling support and high-stress technology, which is applied in the direction of temporary shield, earthwork drilling and bolt installation, etc., can solve the problem that the anchor net cable or anchor-grouting support cannot meet the stability requirements and affect mine safety production and economic benefits Improvement and other issues, to achieve the effect of wide practicability, strong stability and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

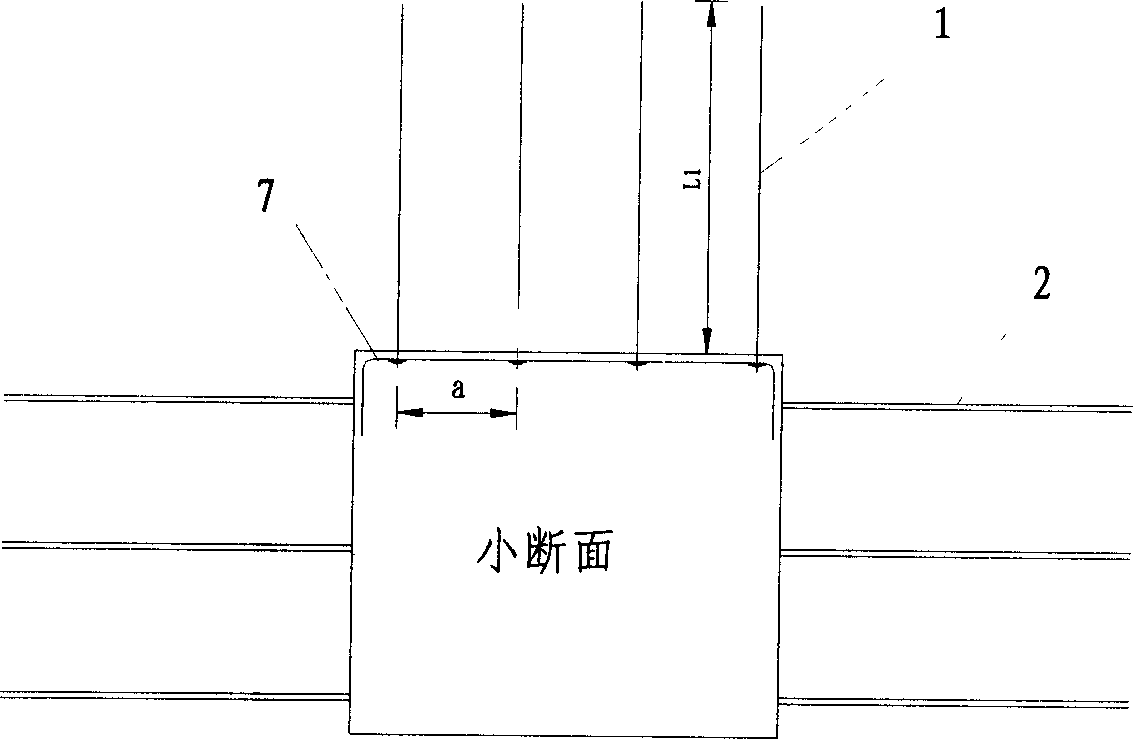

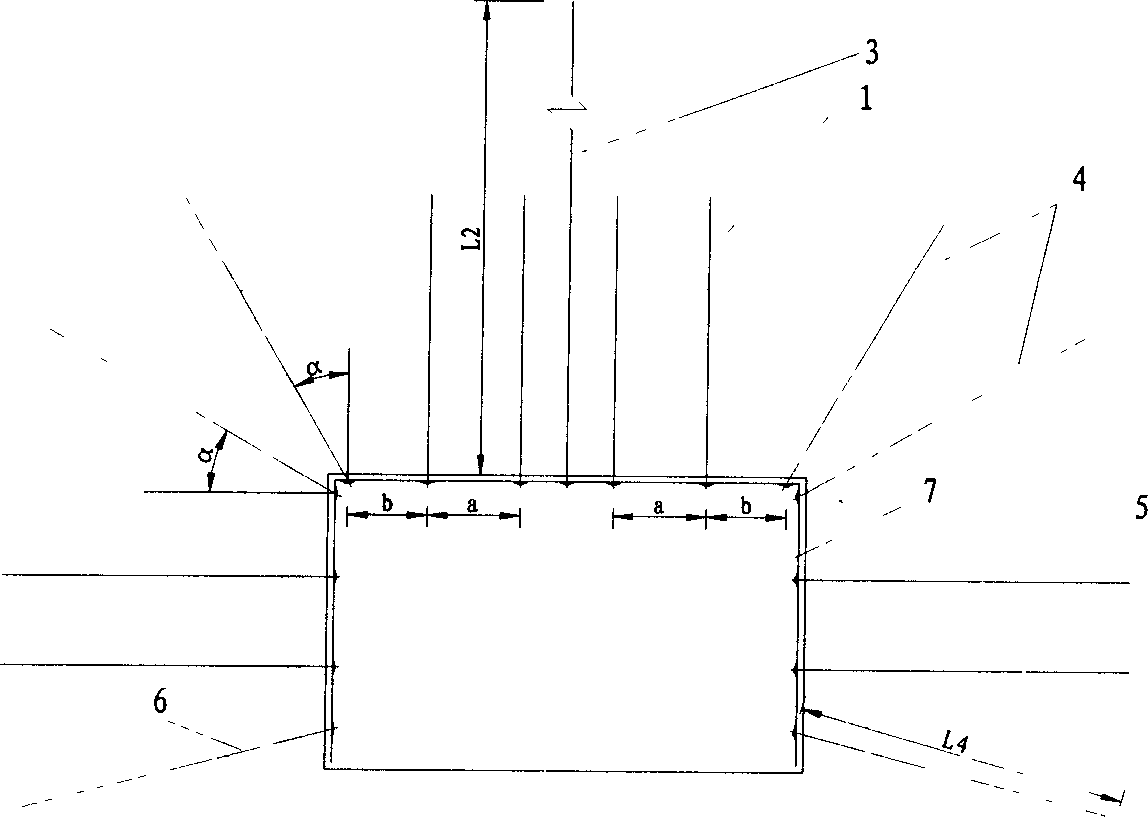

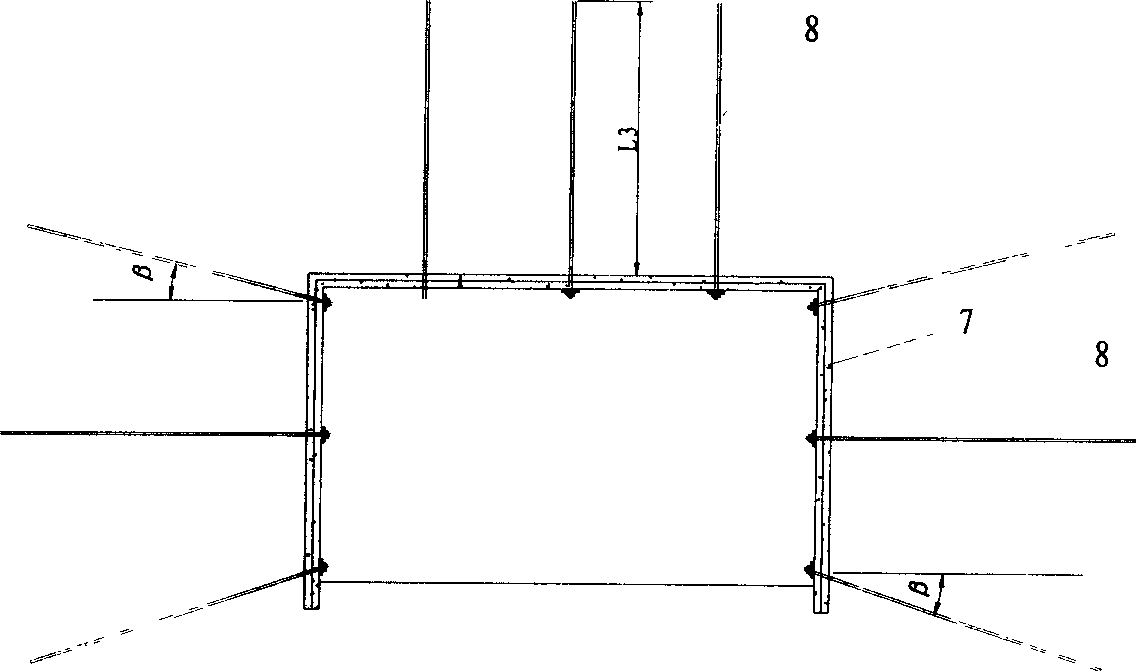

[0015] The three-anchor coupled support method of the high-stress roadway fragmented surrounding rock of the present invention, according to the actual situation on site, firstly analyzes the deformation and failure of the roadway surrounding rock through the investigation and actual measurement of the damage status of the roadway in the complex structure area and the deep-buried high-stress broken surrounding rock roadway Characteristics and failure mechanism; using the surrounding rock loose circle support theory, using the measured surrounding rock loose circle value, determine the technical parameters a, b, c, α, β, L 1 , L 2 , L 3 , L 4 And the grouting parameters; in the construction process, the small section is excavated first and the roof is supported. The anchor bolt spacing of the small section roof support is a, and a=70cm is selected; a prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com