Wheel type ship shape

A ship-type and wheel-type technology, which is applied in the field of ships and wheel-type ships, can solve the problems of high resistance of ships and achieve the effects of reducing navigation resistance, good seakeeping performance, and saving propulsion power and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

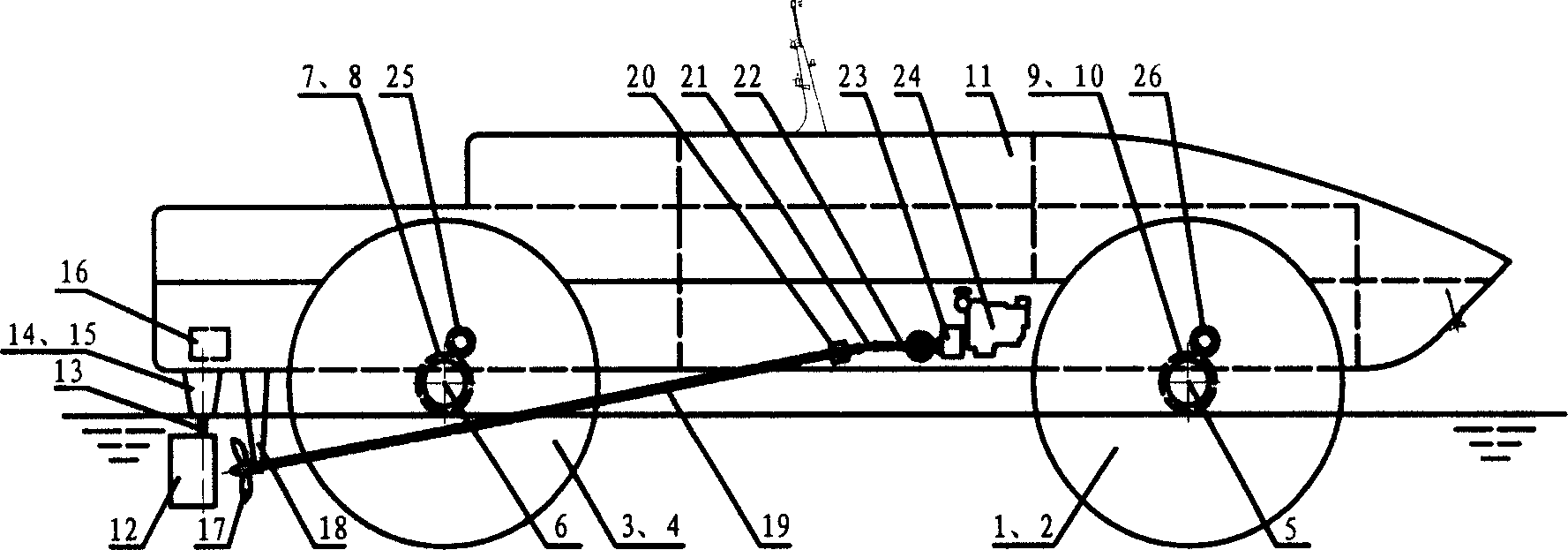

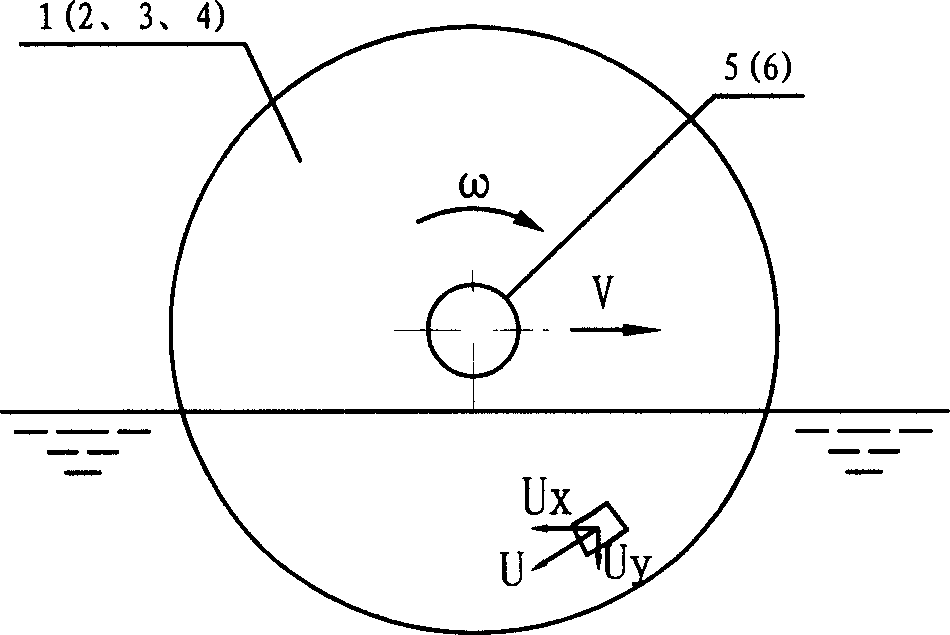

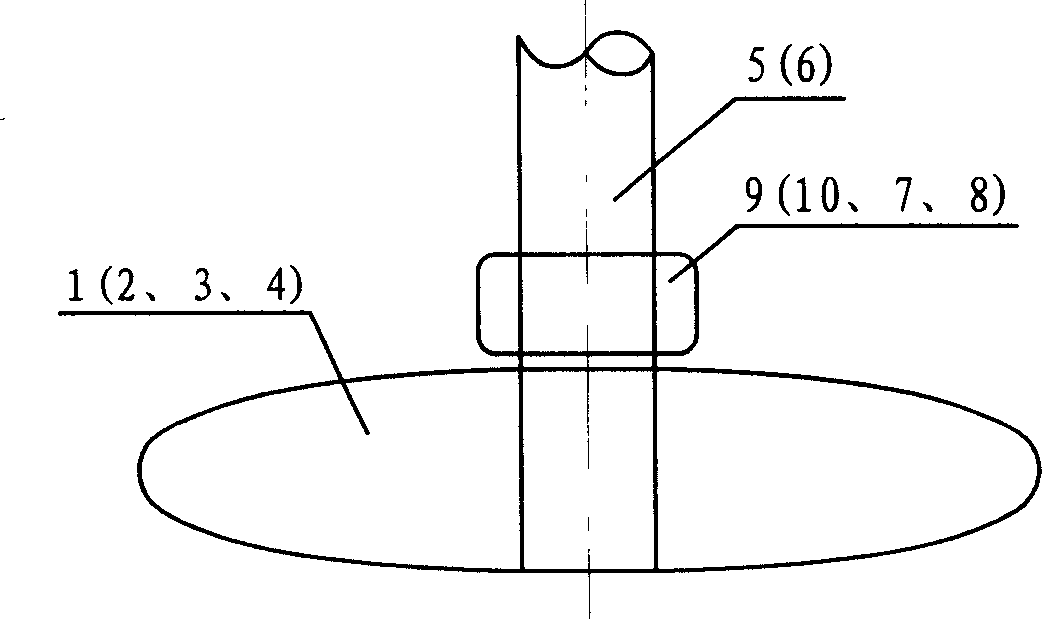

[0014] Such as figure 1 Shown, the present invention comprises: port side buoyancy wheel 1,3, starboard side buoyancy wheel 2,4, buoyancy wheel shaft 5,6, port side buoyancy wheel shaft bearing 7,9, starboard side buoyancy wheel shaft bearing 8,10, water hull 11. The buoyancy wheels 1 and 3 on the port side and the buoyancy wheels 2 and 4 on the starboard side are partially submerged in water, the depth of immersion in water is less than the radius of the buoyancy wheels, and the shape of the section of the buoyancy wheels is streamlined; the hull 11 on the water is supported on the buoyancy wheel shafts 5 and 6, The hull 11 is completely separated from the water surface. The buoyancy wheel 1 on the port side and the buoyancy wheel 2 on the starboard side are connected through the buoyancy wheel shaft 5 to form a buoyancy wheel group. Connect with buoyancy wheel shaft 5,6 by port side buoyancy wheel shaft bearing 7,9 and starboard side buoyancy wheel shaft bearing 8,10 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com