Bushing-type oral implanting device

An implant device and sleeve-type technology, applied in dental implants, medical science, dentistry, etc., can solve the problems of difficult to grasp the degree of bone compression, narrow space for missing teeth, gaps, etc., to improve the quality of implantation and the use effect, Improve the effect of later stability and accurate circumferential positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

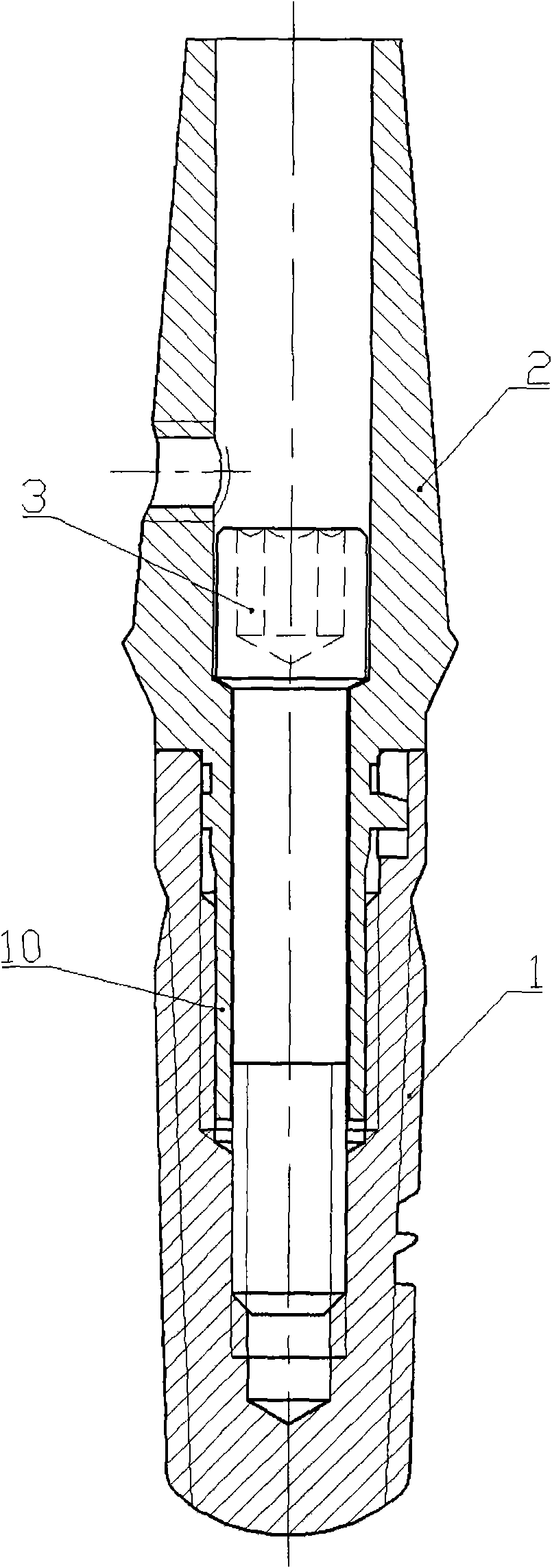

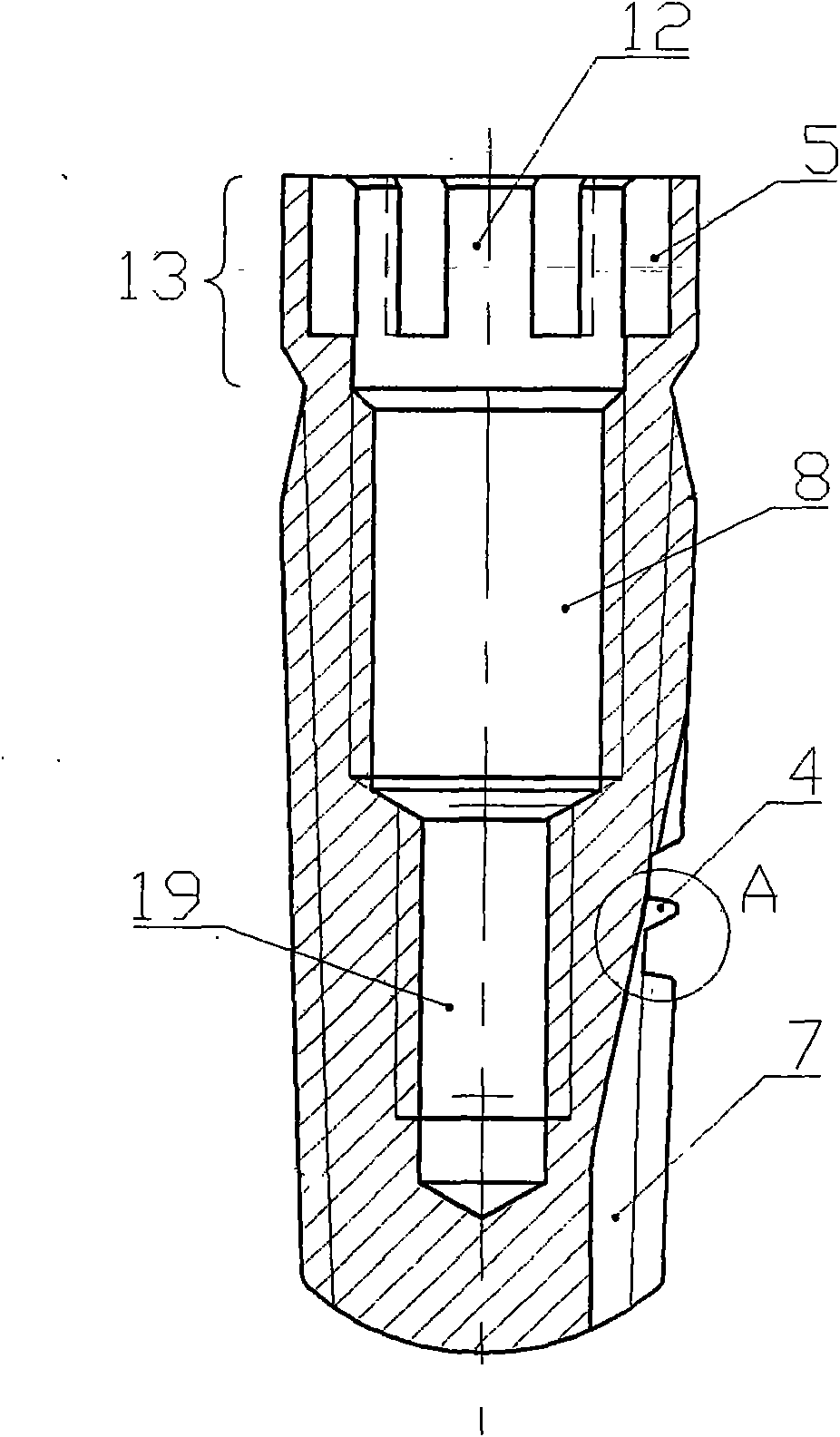

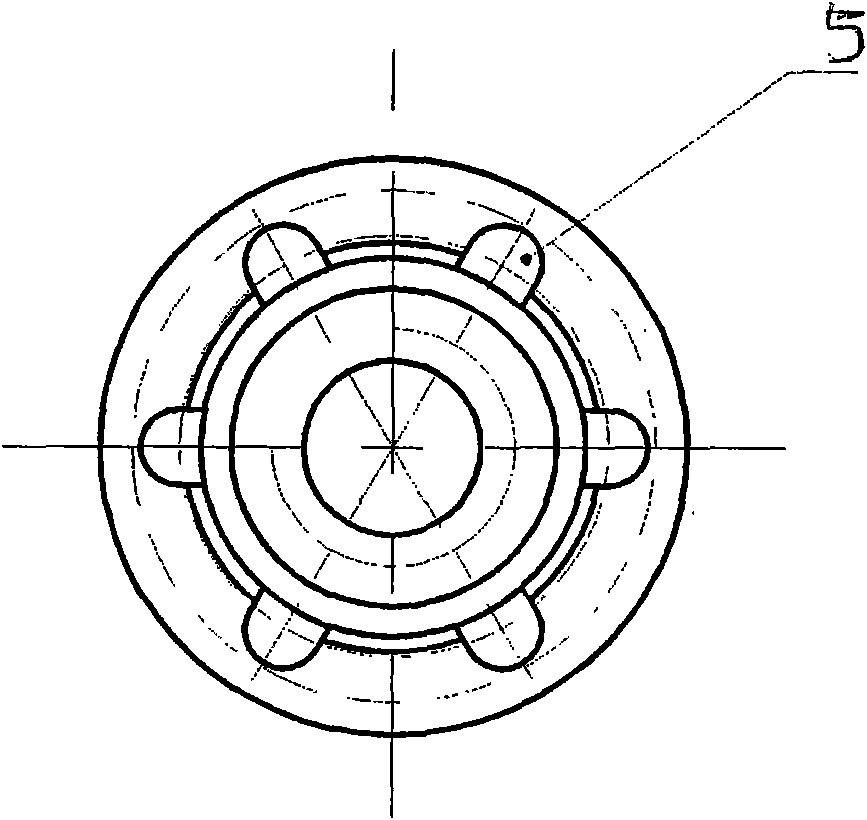

[0023] As shown in the accompanying drawings, a sleeve-type oral implant device includes an implant 1, an abutment 2, and fastening bolts 3. The implant 1 is provided with an external thread 4, the external thread 4 is serrated, and the external thread 4 faces The slope of the tooth surface (thread surface) at the upper end (implant 1 head) is small, and the slope of the tooth surface (thread surface) toward the lower end (implant 1 tail) is large, and the angle of the top angle of the tooth (thread) is 36-40° In order to improve the bone extrusion effect of the implant and disperse the force, improve the initial stability after the operation, make the implant and the alveolar bone firmly combine, improve the implant quality and use effect, the inner cavity of the implant 1 can be composed of three The upper cylindrical surface 12 is evenly distributed with at least two gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com