Implant with bone absorption resistance

An implant and implantation technology, applied in the field of medical equipment, can solve the problems of poor firmness and sealing between the implant and the abutment, the contact area of the taper + anti-rotation part is small, and the stress of the inner hole cannot be transmitted downward. Good initial stability, minimum self-tapping, and the effect of improving initial stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

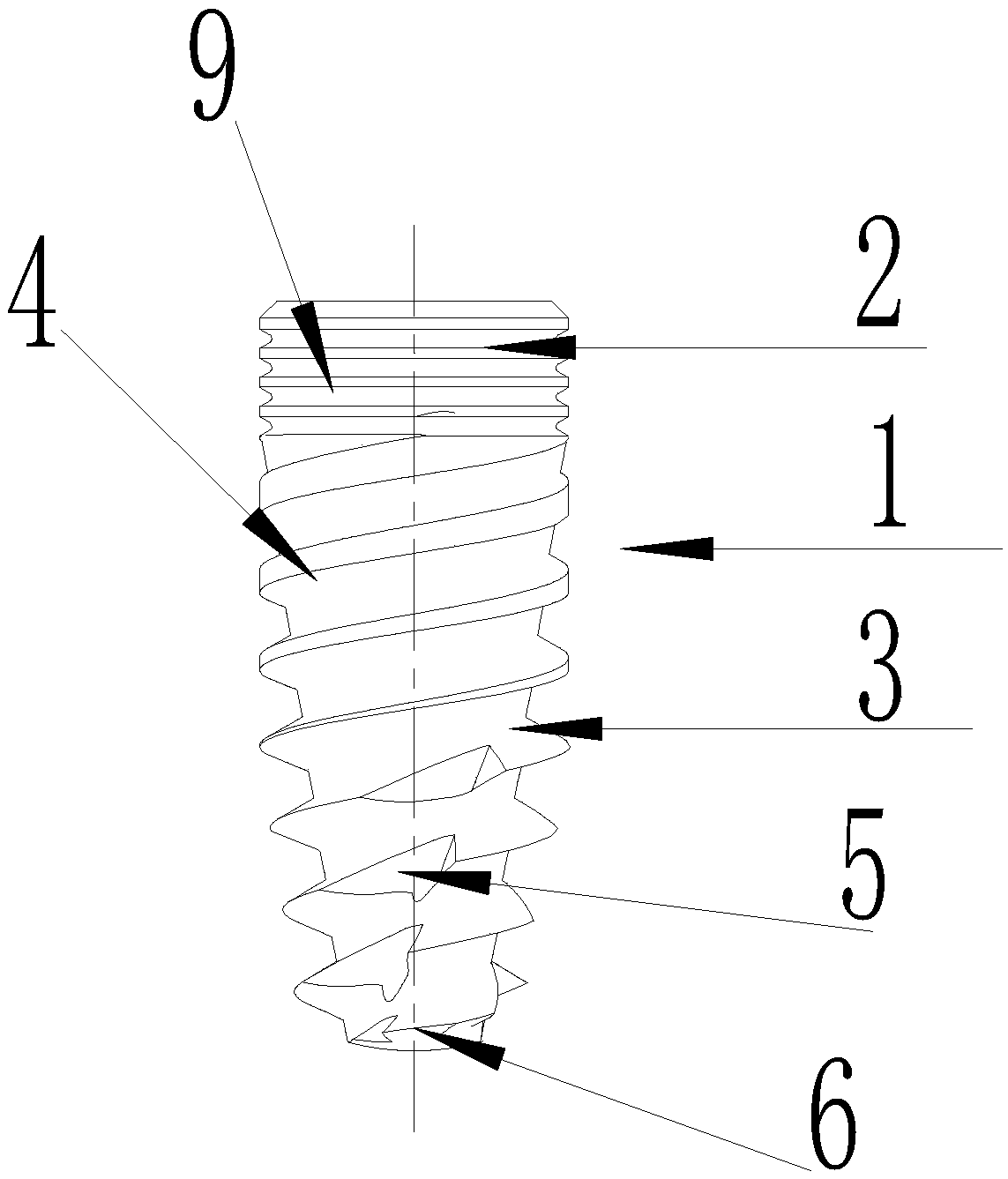

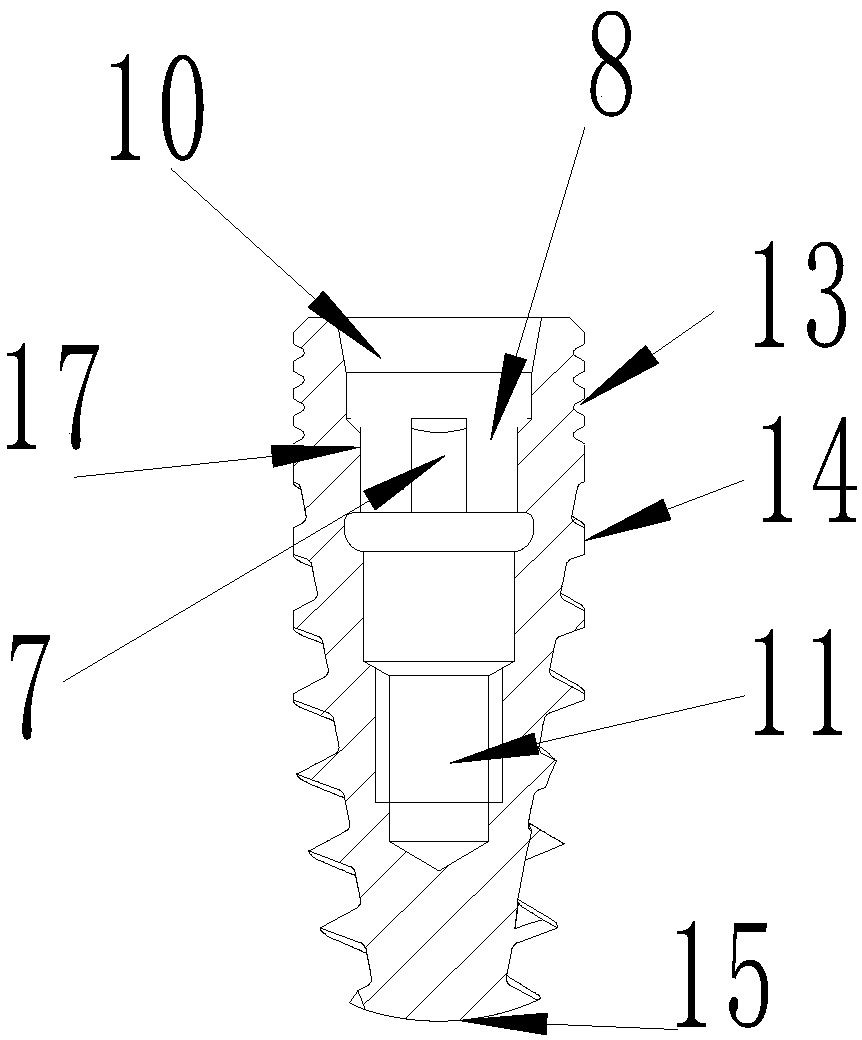

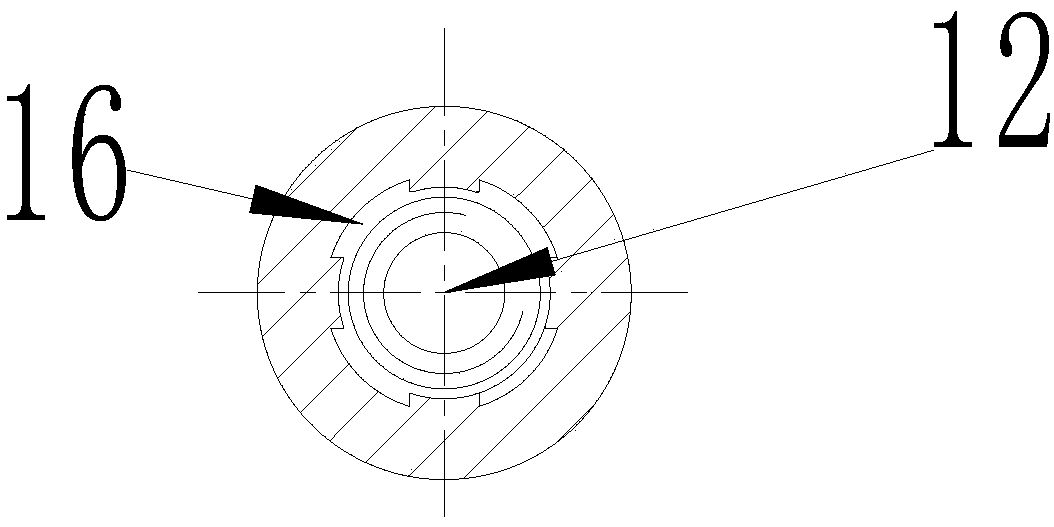

[0030] Such as Figure 1-Figure 3 As shown, an anti-bone resorption implant includes: a main body 1 and an implant hole 17, the implant hole 17 is opened inside the main body 1, wherein:

[0031] The shell of the main body 1 is a vertebral body structure, and the main body 1 is composed of a straight neck 2 and a vertebral body 3, and the straight neck 2 and the vertebral body 3 are integrally connected and formed. 3 is located below the straight neck 2, wherein the straight neck 2 is provided with a collar 9, the collar 9 is provided with a first thread 13, the surface of the vertebral body 3 is provided with a spiral structure 4, so The spiral structure 4 is provided with a second th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com