3D printing method of individualized porous-layer multi-tooth root implant

A 3D printing and implant technology, applied in dentistry, dental implants, dental prosthetics, etc., can solve problems such as shrinkage cavities, inability to make structures, and material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

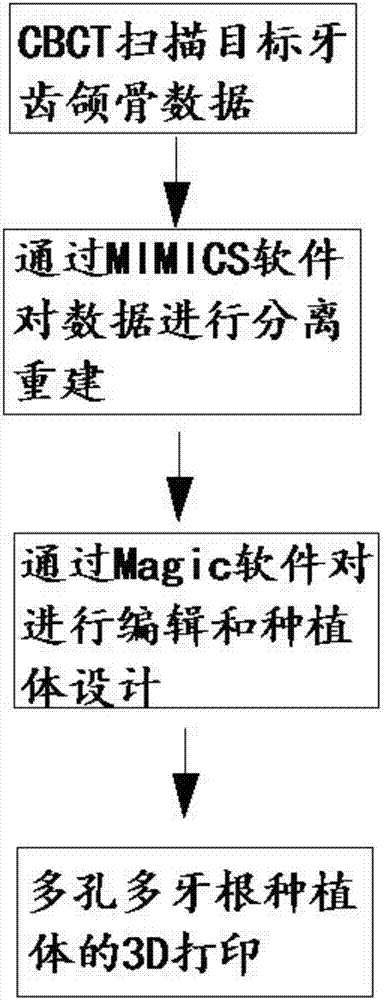

[0038] A 3D printing method for personalized porous-layer multi-root implants, such as figure 1 shown, including the following steps:

[0039] Step one, scan the object and get the data.

[0040] Step 2: Use MIMICS software to separate and reconstruct the data obtained in Step 1 for the scanning area, and obtain the three-dimensional models of the root, socket, crown and dentition area of the subject to be extracted.

[0041] Step 3: Use Magic software to edit the 3D model in step 3, digitally design the root, abutment and crown of the implant and adjust the printing parameters as the implant model to be printed.

[0042] Step 4: Copy the data of the implant model to be printed in Step 3 to a 3D printer for printing to obtain a personalized porous-layer multi-root implant.

[0043] Step 1 is specifically to scan the maxillofacial region of the target with a CBCT scanner to obtain dental and maxillary bone data.

[0044] In step 2, MIMICS software is used to separate and r...

Embodiment 2

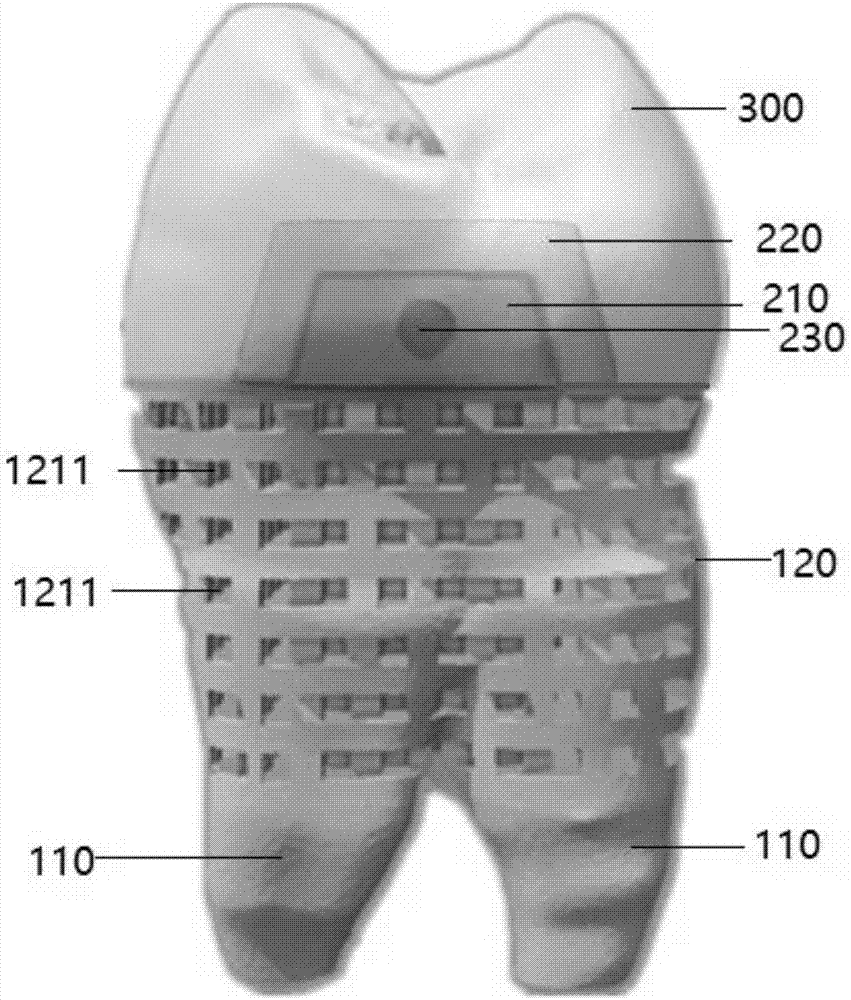

[0055] A 3D printing method for personalized porous-layer multi-root implants, such as Figures 1 to 5 shown, including the following steps:

[0056] (1) Data collection

[0057] Scan the maxillofacial region of the target with a CBCT scanner to obtain dental and maxillary data.

[0058] (2) Data processing

[0059] Use MIMICS software to separate and reconstruct the data obtained in step 1 of the scanned tooth extraction area, and obtain the three-dimensional model of the tooth root, extraction socket, crown and dentition area of the subject to be extracted.

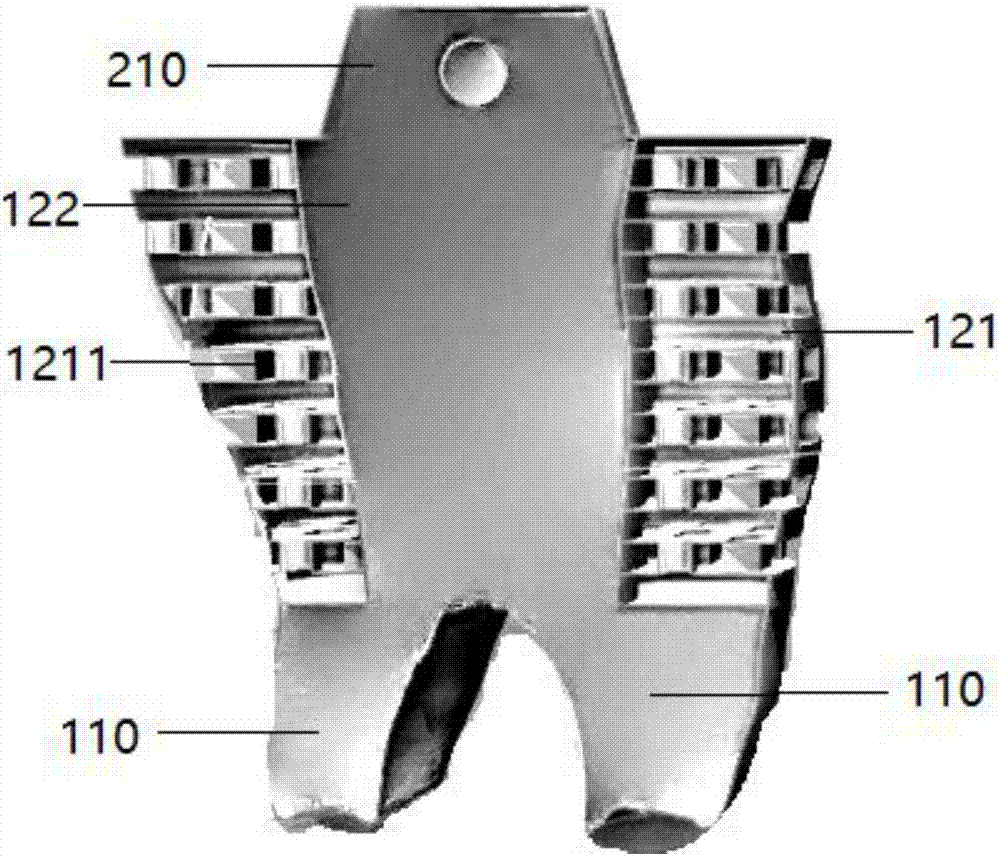

[0060] (3) Specific design of personalized multi-root implants with porous layers

[0061] Use Magic software to edit the 3D model in step 3, digitally design the root, abutment and crown respectively and adjust the printing parameters, as the implant model to be printed. The specific design of the root, abutment and crown is as follows:

[0062] The root is designed to include a root tip and a root body composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com