Acetabular bone file

An acetabular rasp and main body technology, applied in medical science, surgery and other directions, can solve the problems of high operation operation, poor shape accuracy and large design torque of the operator, and achieve complete bone collection, high cutting accuracy and cutting efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

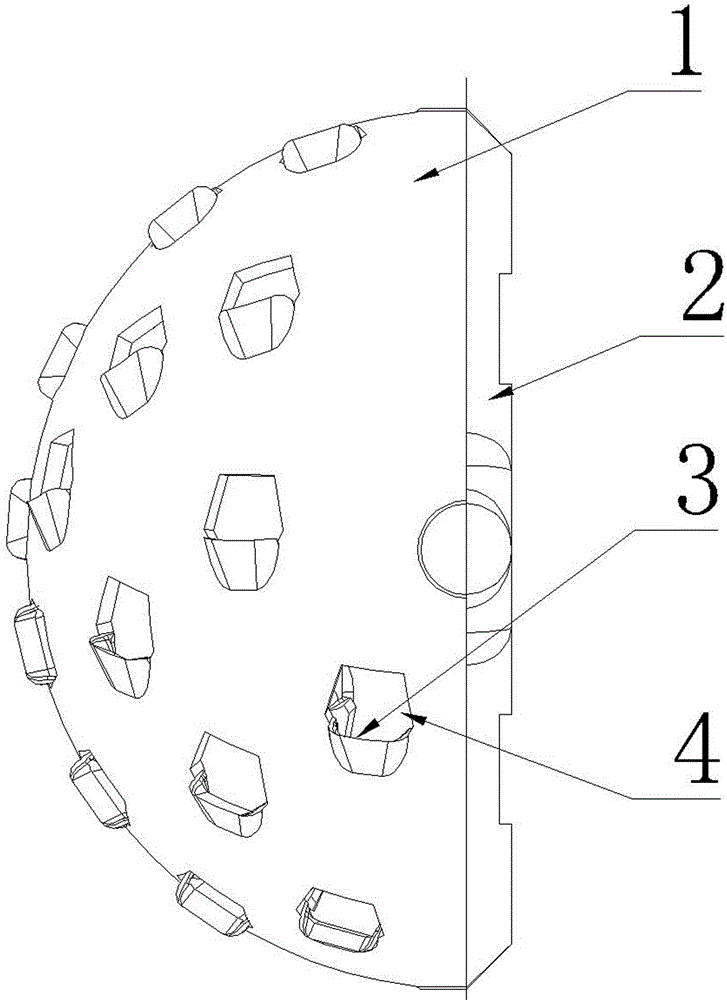

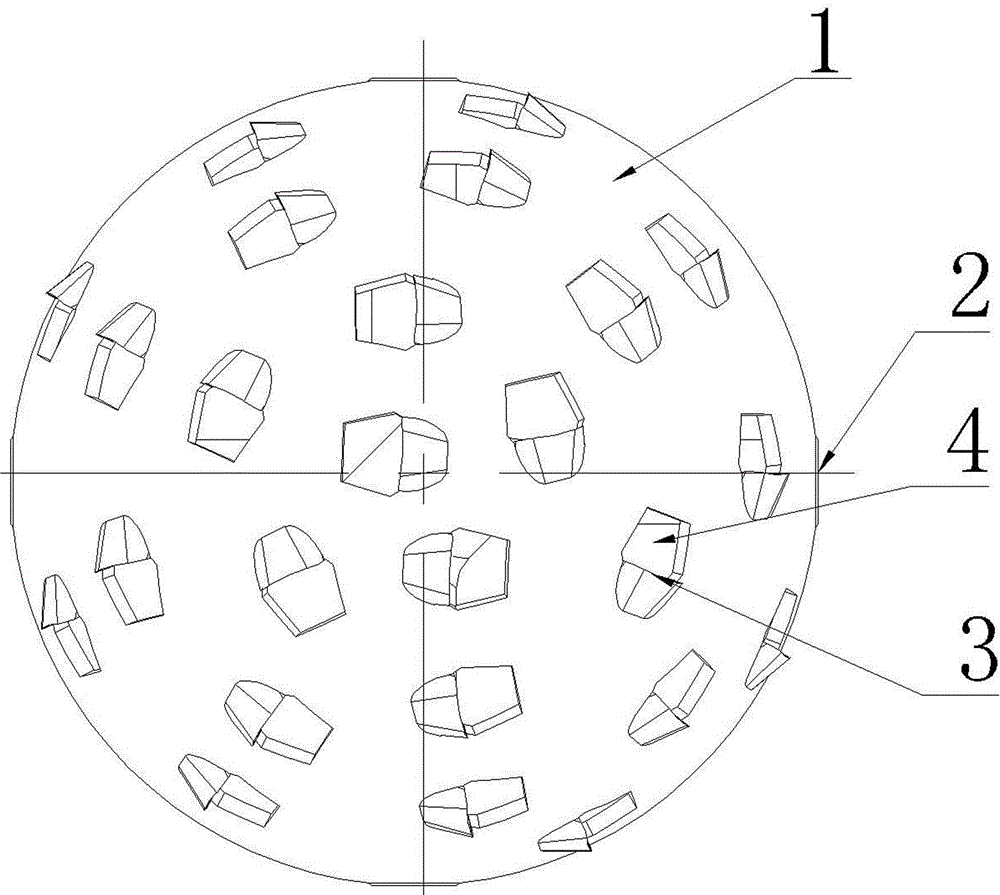

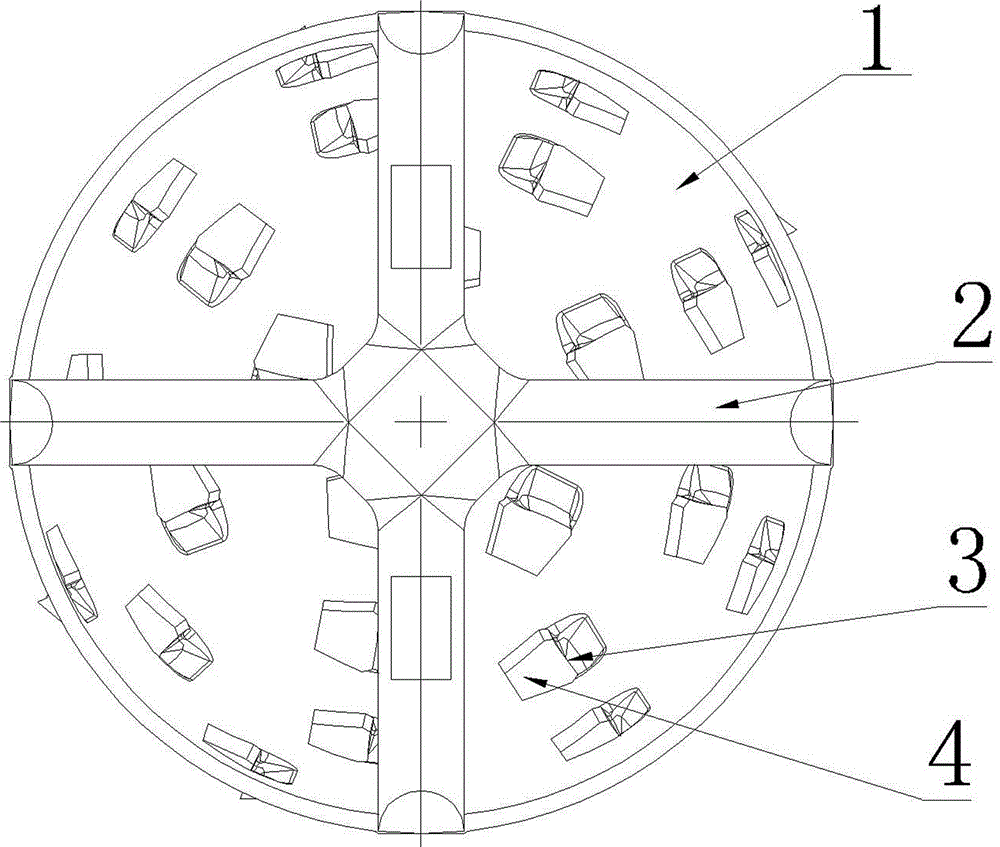

[0017] Refer to attached Figure 1~4 , The acetabular file is composed of a cutting main body 1 and a quick change part 2. The quick change part 2 is fixedly connected with the bottom of the cutting main body 1 . The cutting body 1 is a dome-shaped thin shell, with several raised cutting edges 3 irregularly distributed on the outer surface of the thin shell, and the raised cutting edges 3 spread throughout the expected shape. Each cutting edge 3 is accompanied by a chip hole 4 , and the length direction of the pin hole 4 is perpendicular to the cutting edge 3 . The cutting edge 3 is partially parallel to the outer surface of the dome-shaped thin shell. The length of the cutting edge parallel to the outer surface of the dome-shaped thin shell is not less than 0.5mm.

[0018] The wall thickness of the cutting main body 1 is not greater than 3mm.

[0019] The quick change part 2 is in the shape of a cross bracket or a disc with holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com