Artificial hip joint and manufacturing method thereof

A hip joint and artificial technology, applied in the direction of hip joints, joint implants, joint implants, etc., can solve the problem of low production efficiency of mechanical processing, short service life of artificial hip joint prosthesis, and complicated manufacturing process of joint accessories and other issues to achieve the effect of good reproducibility, increased cost, and high product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

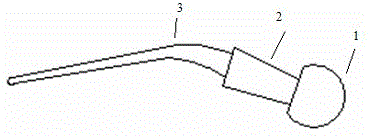

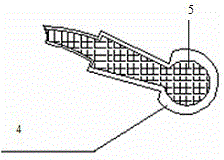

[0022] figure 1 It is a structural schematic diagram of the artificial hip joint of the present invention, such as figure 1 The artificial hip joint of the present invention is shown, including acetabulum 1, femur 2, joint handle 3, figure 2 It is a schematic diagram of the longitudinal section structure of the artificial hip joint of the present invention, as figure 2 The artificial hip joint shown is composed of an inner layer 5 of the artificial hip joint and an outer layer 4 of the artificial hip joint, the outer layer 4 covers the inner layer 5, the outer layer 4 is a wear-resistant material layer, and the inner layer 5 is a metal material layer, wherein , the thickness of the outer layer 4 is less than or equal to the thickness of the inner layer 5 . The outer layer 4 is a quartz material layer, and the inner layer is 316 stainless steel. As an alternative, the outer layer 4 can also be a layer of diamond material, a layer of ceramic material, a layer of aluminum ox...

Embodiment 2

[0025] One of the preparation methods of embodiment 1:

[0026] (1) Feed stainless steel and zirconia. The stainless steel layer is used as the inner layer of the artificial hip joint, and the zirconia layer is used as the outer layer of the artificial hip joint. Co-injection is performed at 150°C, the mold temperature is 60°C, and the injection pressure is 100MPa , to obtain the embryo;

[0027] (2) Then degrease the blank, the degreasing temperature is 40°C, and the time is 6 hours to obtain the degreasing part; after degreasing, the product is sintered at 1200°C to obtain the artificial hip joint product.

Embodiment 3

[0029] Two of the preparation method of embodiment 1:

[0030] (1) Feed stainless steel and zirconia. The stainless steel layer is used as the inner layer of the artificial hip joint, and the zirconia layer is used as the outer layer of the artificial hip joint. Co-injection is carried out at 100°C, the mold temperature is 20°C, and the injection pressure is 200MPa , to obtain the embryo;

[0031] (2) Then degrease the blank, the degreasing temperature is 40°C, and the time is 10 hours to obtain the degreasing part; after degreasing, the product is sintered at a sintering temperature of 1360°C to obtain the artificial hip joint product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com