High-temperature rate type lithium cobalt oxide anode material and preparation method thereof

A cathode material, lithium cobalt oxide technology, applied in chemical instruments and methods, battery electrodes, cobalt compounds, etc., can solve the problems of cathode material structure collapse, poor material processing performance, poor rate performance, etc., and achieve compaction performance. Good, strong thermal stability performance and chemical stability performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

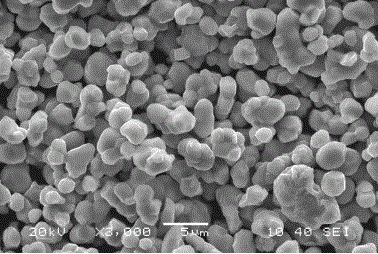

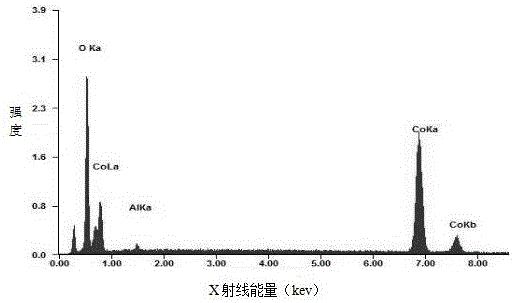

[0039] A high-temperature rate type lithium cobaltate positive electrode material of the present invention is formed by lithium cobaltate doped with metal element Al, and its molecular formula is LiCo 0.998 Al 0.002 o 2 , its preparation method comprises the following steps:

[0040] (1) Dissolve CoCl with deionized water 2 、Al 2 (SO 4 ) 3 , prepared into an aqueous solution with a molar ratio of Co:Al=100:0.2 and a Co ion concentration of 1.25mol / L, and the obtained aqueous solution and NH 4 HCO 3 Add the solution into the reaction kettle to make it react and crystallize, and stir at the same time, and control the pH value of the reaction system to 7.0-8.0, the flow rate is 500L / h, the stirring speed is 50rpm, the crystallization temperature is 20°C, and the continuous reaction repeats crystallization for 4 Centrifugal filtration is carried out after the times to obtain the precursor cobalt salt doped with metal element Al;

[0041] (2) Decompose the precursor cobalt ...

Embodiment 2

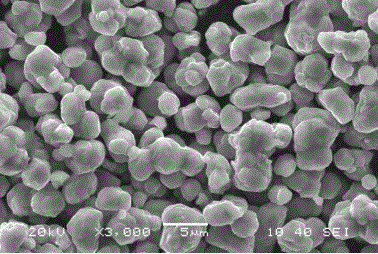

[0046] A high-temperature rate type lithium cobaltate positive electrode material of the present invention is formed by lithium cobaltate doped with metal element Al, and its molecular formula is Li 1.05 co 0.9965 Al 0.0035 o 2 , its preparation method comprises the following steps:

[0047] (1) Dissolve CoCl with deionized water 2 、Al 2 (SO 4 ) 3 , prepared into an aqueous solution with a molar ratio of Co:Al=100:0.3 and a Co ion concentration of 1.25mol / L, and the obtained aqueous solution and NH 4 HCO 3 Add the solution into the reaction kettle to make it react and crystallize, while stirring, and control the pH value of the reaction system to 7.0-8.0, the flow rate is 1000L / h, the stirring speed is 120rpm, the crystallization temperature is 50°C, and the continuous reaction repeats crystallization for 6 Centrifugal filtration is carried out after the times to obtain the precursor cobalt salt doped with metal element Al;

[0048] (2) Decompose the precursor cobalt ...

Embodiment 3

[0053] A high-temperature rate type lithium cobaltate positive electrode material of the present invention is formed by lithium cobaltate doped with metal element Al, and its molecular formula is Li 1.10 co 0.995 Al 0.005 o 2 , its preparation method comprises the following steps:

[0054] (1) Dissolve CoCl with deionized water 2 、Al 2 (SO 4 ) 3 , prepared into an aqueous solution with a molar ratio of Co:Al=100:0.4 and a Co ion concentration of 1.25mol / L, and the obtained aqueous solution was mixed with (NH 4 ) 2 CO 3 Add the solution into the reaction kettle to make it react and crystallize, and stir at the same time, and control the pH of the reaction system to be 7.0-8.0, the flow rate is 2000L / h, the stirring speed is 200rpm, the crystallization temperature is 80°C, and the continuous reaction repeats crystallization for 8 Centrifugal filtration is carried out after the times to obtain the precursor cobalt salt doped with metal element Al;

[0055] (2) Decompose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com