Ground compacting device for construction

A technology of building construction and bearing platform, which is applied in construction, infrastructure engineering, soil protection, etc. It can solve problems such as poor compaction effect, unfavorable construction construction, and inability to adjust the size of the ground compaction force, so as to achieve compaction effect Good, ingenious structure, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

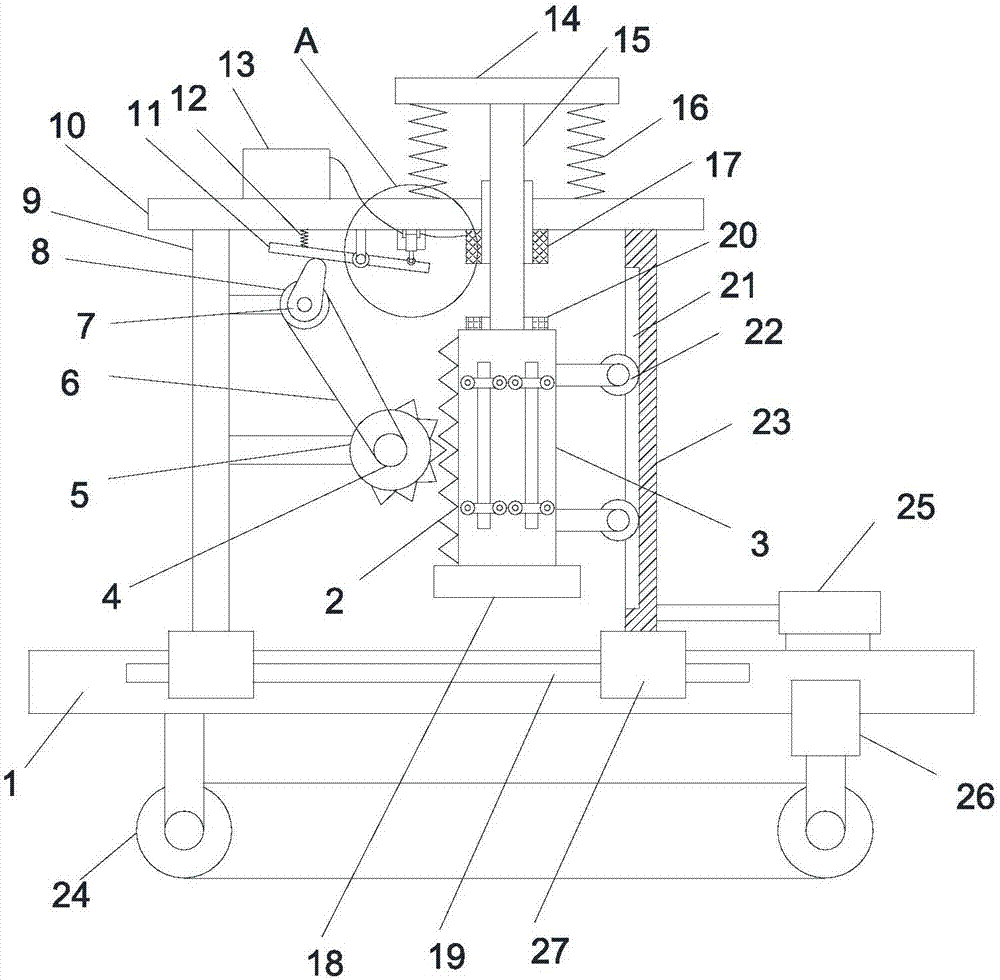

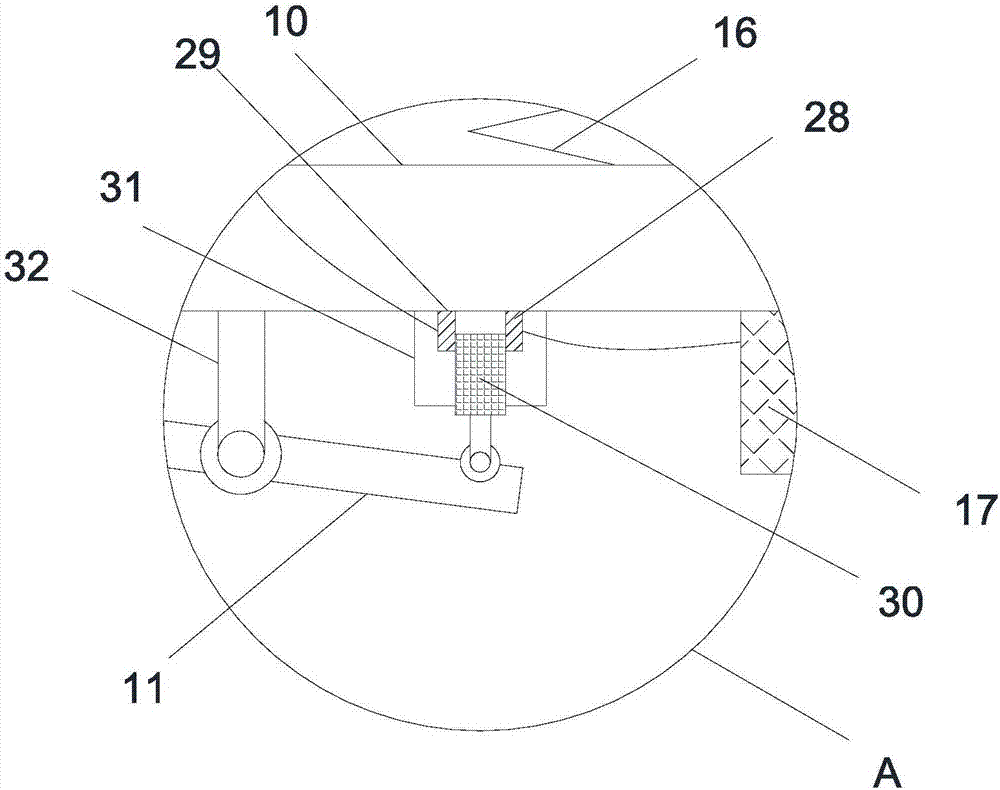

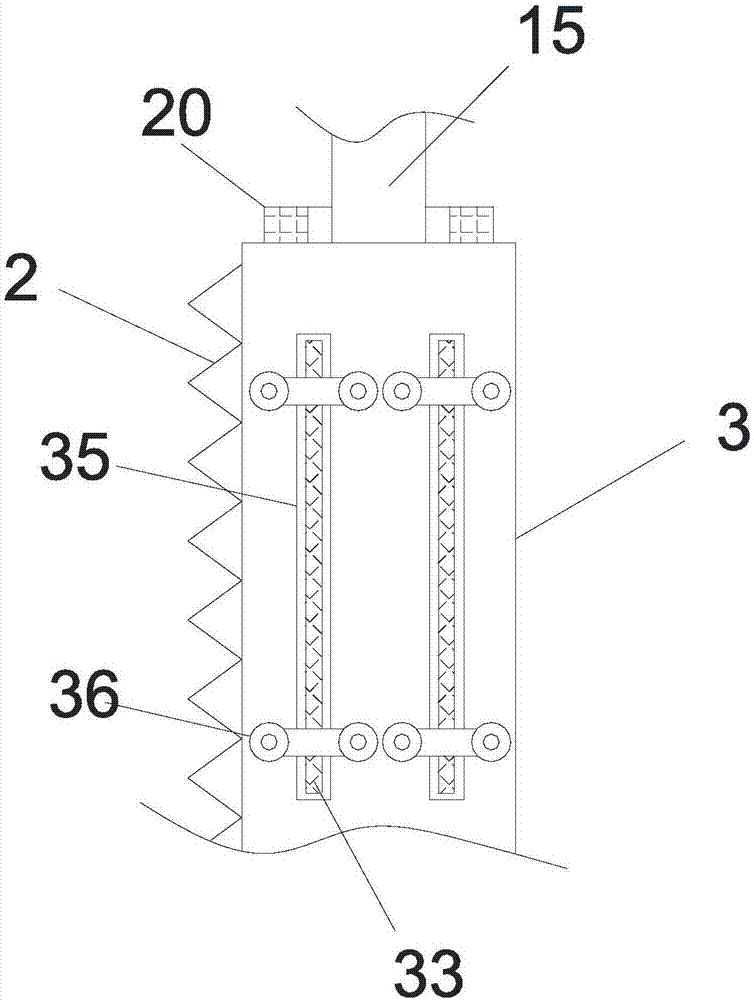

[0020] see Figure 1-4 , a ground tamping device for building construction, comprising a bearing platform 1, the side of the bearing platform 1 is provided with a transverse chute 19, and the horizontal chute 19 is horizontally slidably provided with two slide plates 27, and the two slide plates 27 are respectively vertically Straight welding is fixedly installed with left vertical plate 9 and right vertical plate 23, and left vertical plate 9 and right vertical plate 23 top levels are fixedly installed with horizontal plate 10, and horizontal plate 10 bottom is fixedly equipped with electromagnet 17, and vertical plate 10 is vertically installed. The sliding type is provided with a slide bar 15 through which the slide bar 15 passes through an electromagnet 17. A top plate 14 is provided on the top of the slide bar 15. A return spring 16 is connected betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com