Piston used for connection rod-free reciprocating-rotating movement converting device and equipment thereof

A technology of rotary motion, conversion device, applied in the direction of piston, engine element, machine/engine, etc., to avoid the effect of piston sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

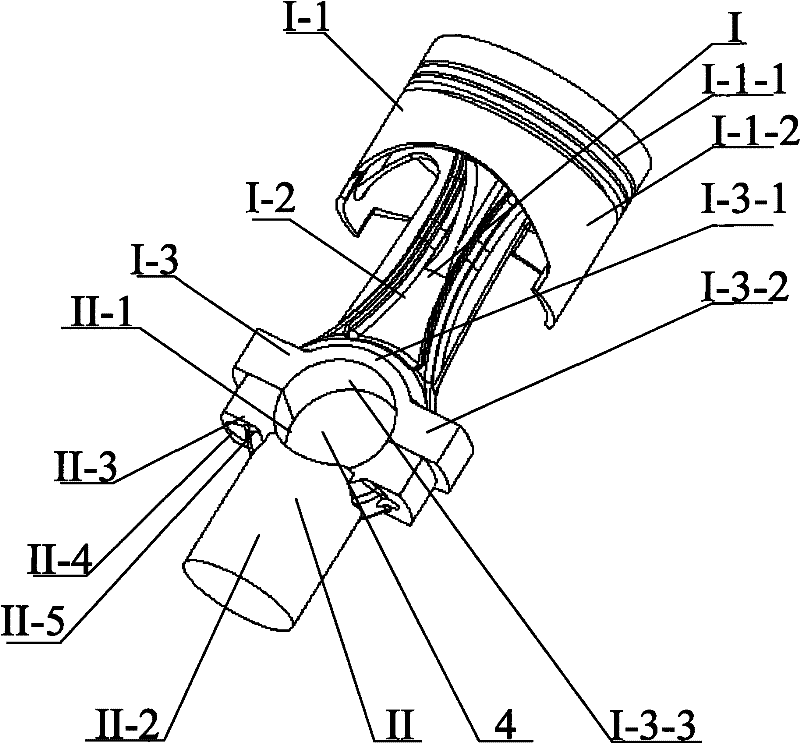

[0035] Please see figure 1 , this figure is the piston used in the internal combustion engine using the crank-slider mechanism or end shaft-moving shaft mechanism provided by the first embodiment of the present invention.

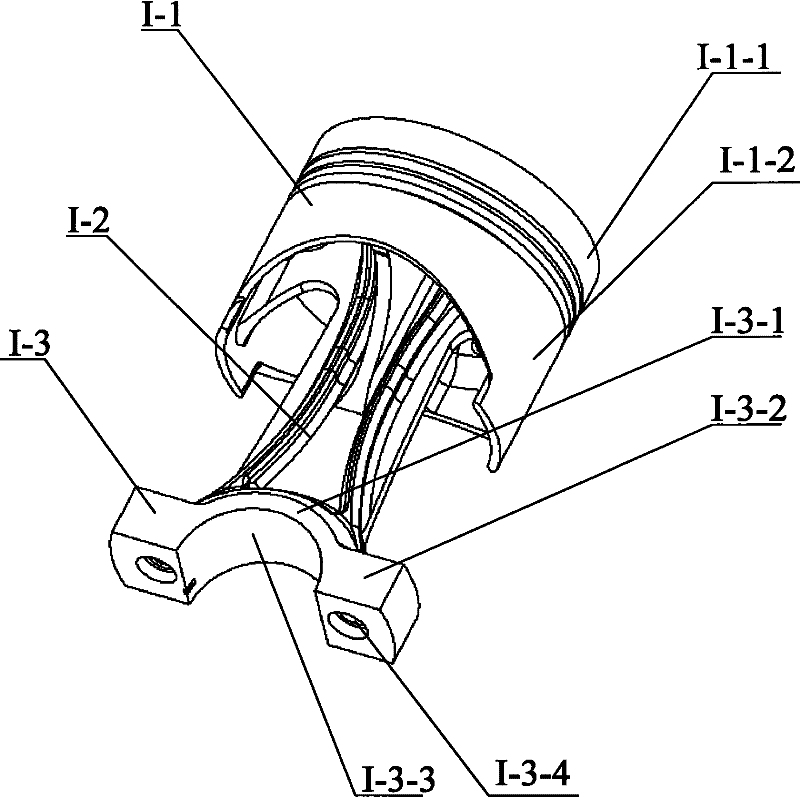

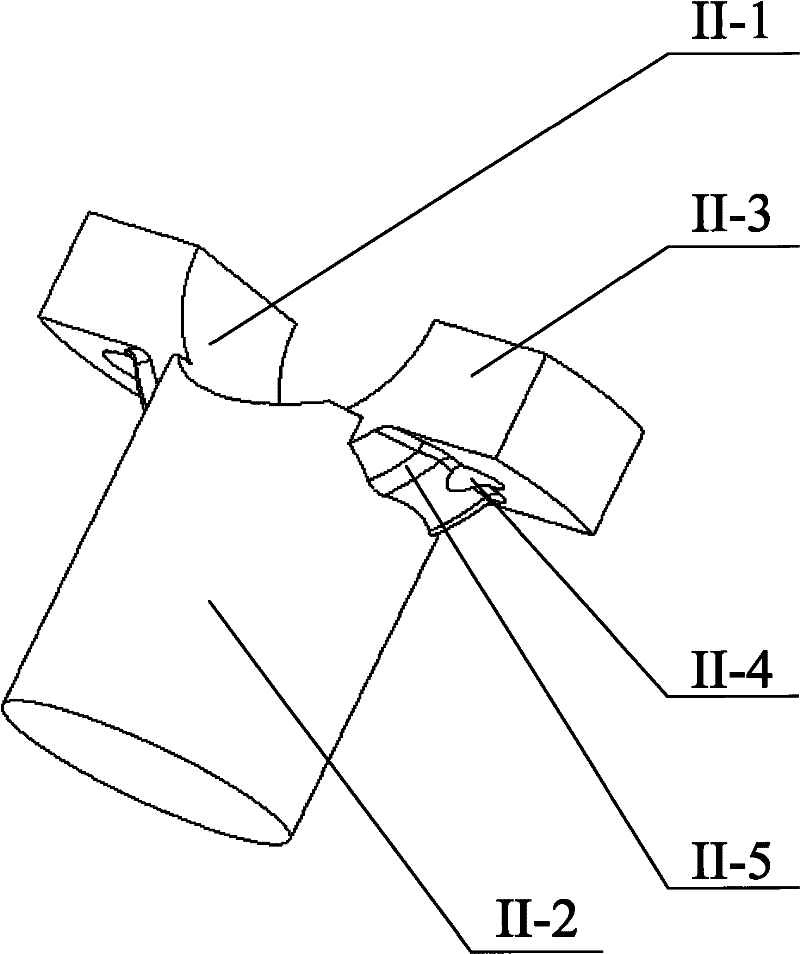

[0036] figure 1 The piston is shown as a single-acting piston with one piston head. From the longitudinal direction, the piston includes a piston head I and an auxiliary guide part II. In this embodiment, these two parts are made separately, from figure 1 It can be seen from the figure that the ears on both sides of the upper end of the auxiliary guide part II are respectively provided with positioning threaded holes, and the corresponding positioning threaded holes are also provided on the piston head I; through this positioning connection structure, the above-mentioned piston head can be Part I and auxiliary guide part II are fixed as one. figure 2 It is a perspective view of the above-mentioned piston head 1, image 3 It is a perspective view of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com