Road asphalt paving and compacting device

A compacting device and road asphalt technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of low work efficiency and single function, and achieve the effect of adjusting the leveling thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

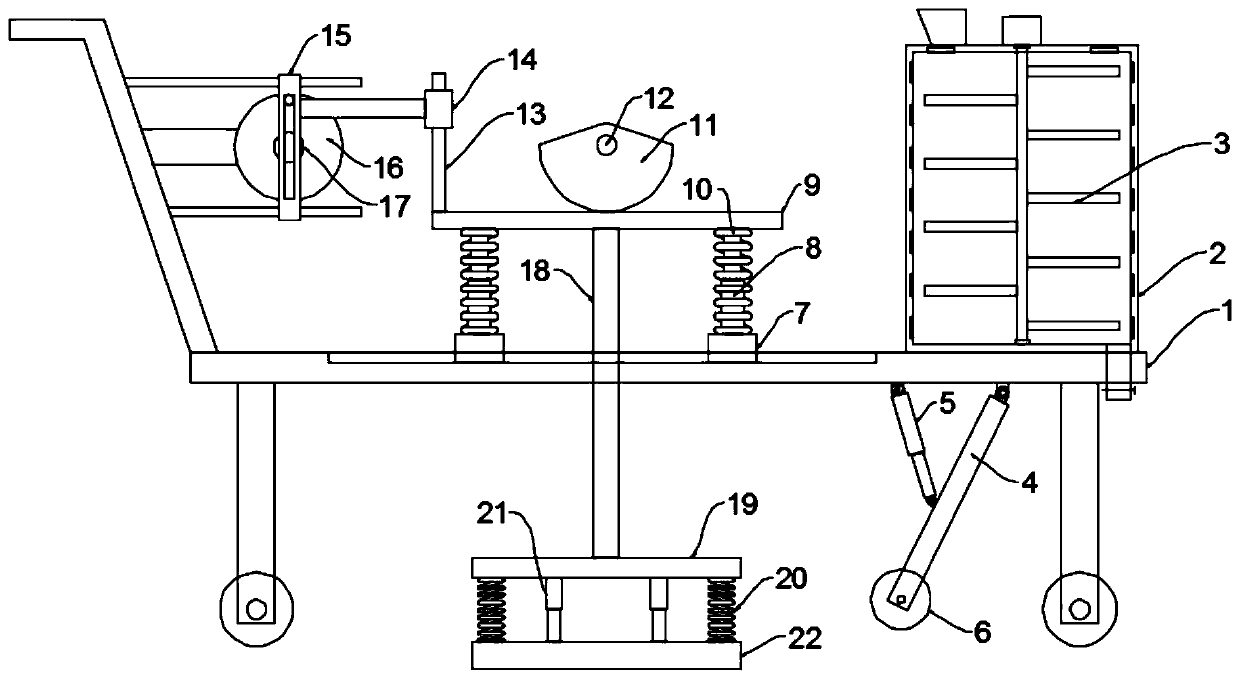

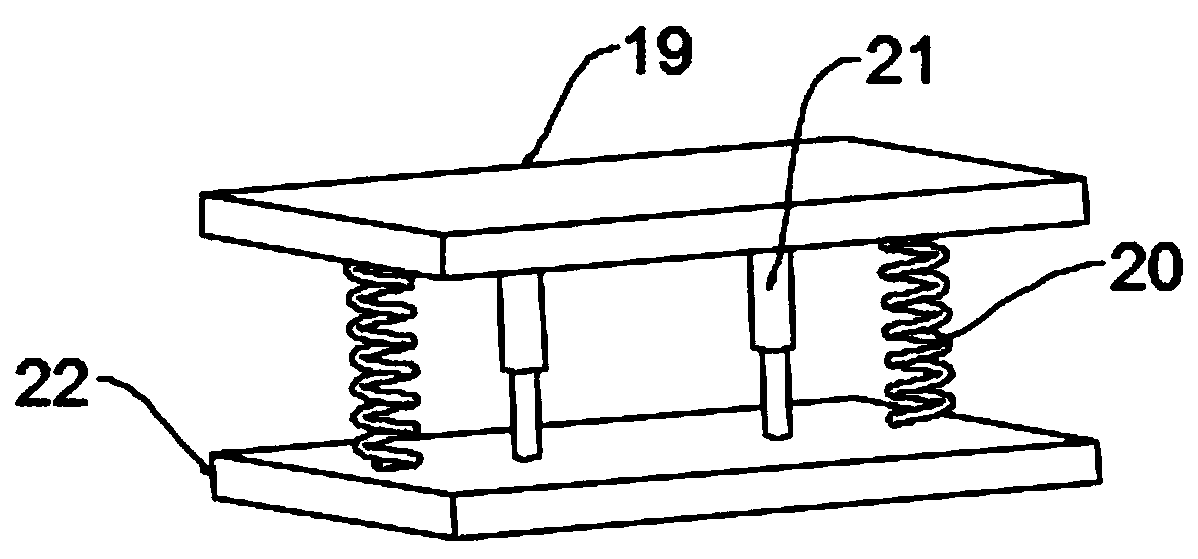

[0024] see Figure 1~2 , in an embodiment of the present invention, a road asphalt paving and compacting device includes a cart 1 and a paving unit, the cart 1 includes a frame, a hand frame fixed at one end of the frame, and fixed at the bottom of the frame evenly and symmetrically The supporting legs and the rollers installed at the bottom of the supporting legs are self-locking rollers to facilitate the movement of the device. The laying unit is installed on the trolley 1, and the laying unit includes a heating box 2 for heating asphalt and a heating box for heating asphalt. The leveling roller 6 for paving asphalt, the top of the heating box 2 is provided with a feed port, the bottom of the heating box 2 is provided with a discharge port, a valve is installed on the discharge port, and an electric heating element for heating and A stirring unit 3 for stirring. In this embodiment, the stirring unit 3 includes a stirring shaft, a stirring rod fixed on the stirring shaft and ...

Embodiment 2

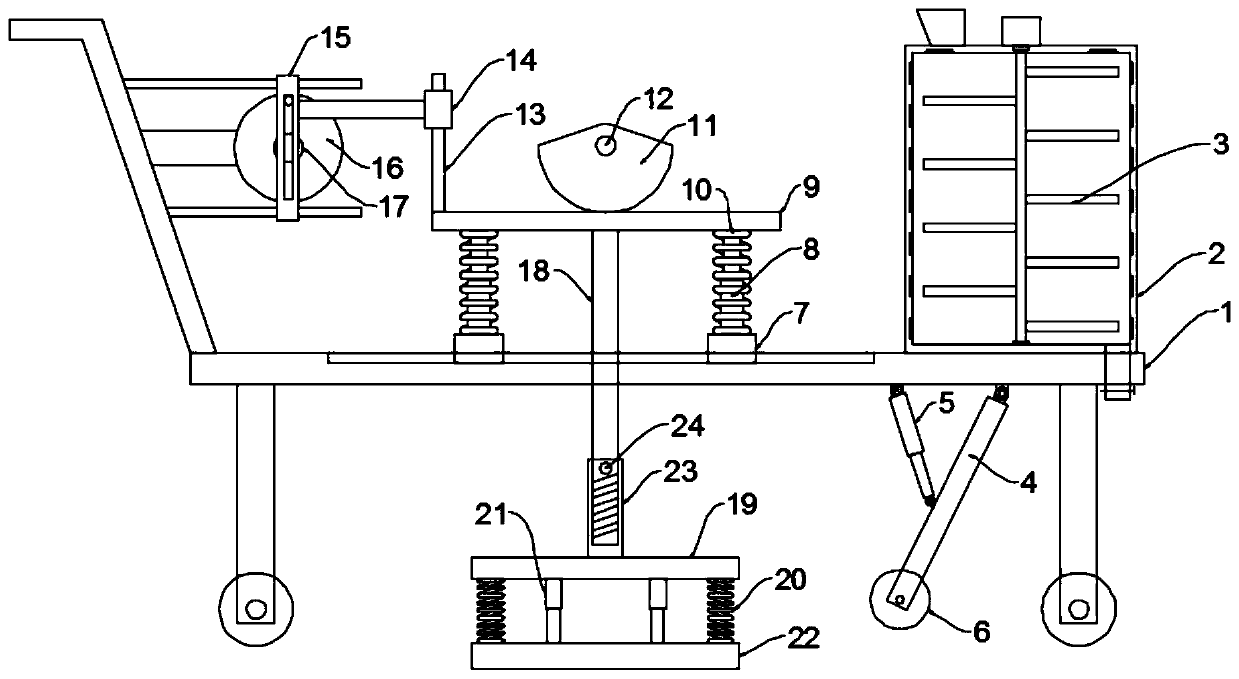

[0027] see image 3The difference between this embodiment of the present invention and Embodiment 1 is that, further, the connecting plate 19 is threadedly connected to the connecting rod 18, the top of the connecting plate 19 is fixed with an internal thread sleeve 23, and the bottom of the connecting rod 18 is provided with There is an external thread that cooperates with the internal thread sleeve 23, and a fastening bolt 24 is also connected between the internal thread sleeve 23 and the connecting rod 18. By adjusting the position of the connecting rod 18 and the connecting plate 19, the pressure of the pressing plate 22 when pressing down can be adjusted. Pressure, better adapt to construction needs.

[0028] The working principle of the present invention is: when working, the first motor 12 drives the sector cam 11 to rotate, and when the arc edge of the convex head of the sector cam 11 contacts the drive plate 9, it drives the drive plate 9 to move downward, and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com