Automatic material spreading device for similar material simulation test, and use method of automatic material spreading device

A similar material, simulation test technology, applied in the field of automatic laying equipment, can solve the problems of unguaranteed consistency of simulated rock stratum compactness and similarity ratio, high maintenance and repair costs, and high equipment failure rate. Good tamping effect, low maintenance and repair costs, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings.

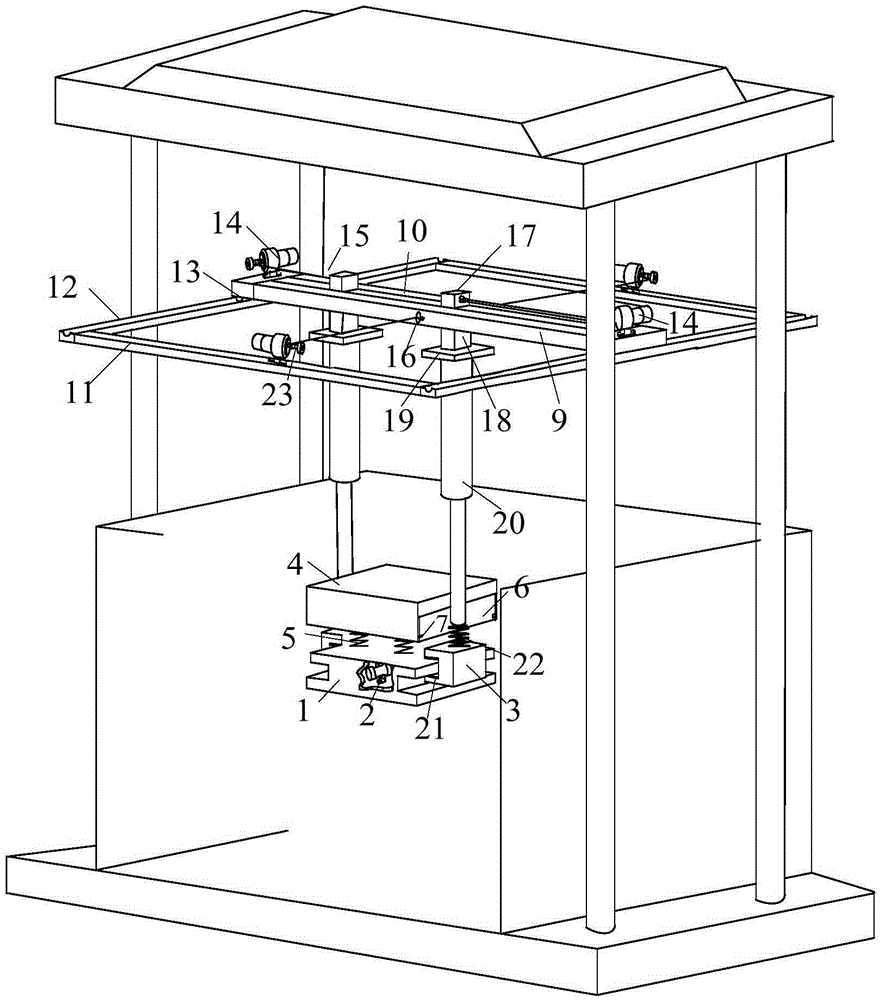

[0058] Such as figure 1 As shown, the automatic material spreading device for similar material simulation test of the present invention includes a mounting bracket, a hydraulic cylinder 20, a limit block 3, a vibrating device 1 and a material holding box 4;

[0059] The above-mentioned mounting bracket is a rectangular frame, and the four corners of the above-mentioned rectangular frame are respectively installed on four uprights of a similar simulation test device;

[0060] The front, rear, left and right four frames of the above-mentioned mounting bracket are all first square columns 11, wherein the upper surfaces of the left first square column 11 and the right first square column 11 are respectively provided with first sliding slot 12;

[0061] The mounting bracket also includes a beam 9, and the left and right ends of the beam 9 are respectively provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com