Positive electrode material, preparation method thereof and lithium ion battery

A positive electrode material and substrate technology, applied in the field of positive electrode material and its preparation, and lithium ion battery, can solve the problems such as the initial discharge capacity and cycle performance of quaternary positive electrode material to be improved, and achieve the improvement of chemical stability, crystallinity, The effect of reducing polarization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

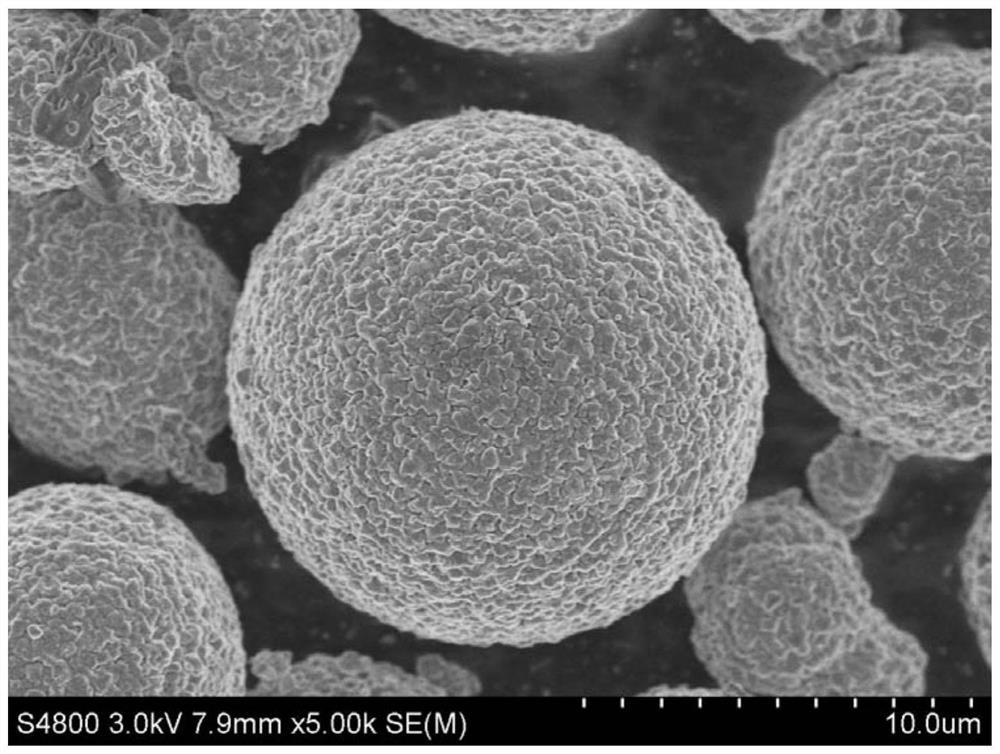

[0083] This embodiment provides a Li 6.5 Y 0.5 Zr 1.5 o 7 Coated boron-tungsten co-doped nickel-cobalt-manganese-aluminate positive electrode material and a preparation method thereof, the method comprising the following steps:

[0084] (1) A mixed solution containing nickel sulfate, cobalt sulfate and manganese sulfate with a metal ion concentration of 120g / L (Ni, Co, Mn molar ratio is 8.9:0.7:0.4), 20g / L sodium metaaluminate solution, 300g / L The sodium carbonate solution and 5mol / L ammonia water were reacted at 50°C and the pH value was 12.0 to obtain the precursor.

[0085] (2) Mix 20kg of the precursor obtained in step (1), 13.8kg of lithium nitrate, 140g of tungsten trioxide and 65 grams of boric acid, and sinter at 700°C for 10 hours to obtain the substrate; lithium ions in lithium nitrate and the precursor The molar ratio of nickel ions in is 1.05.

[0086] (3) Mix lithium hydroxide, yttrium oxide, and zirconium dioxide in a certain molar proportion evenly, so that...

Embodiment 2

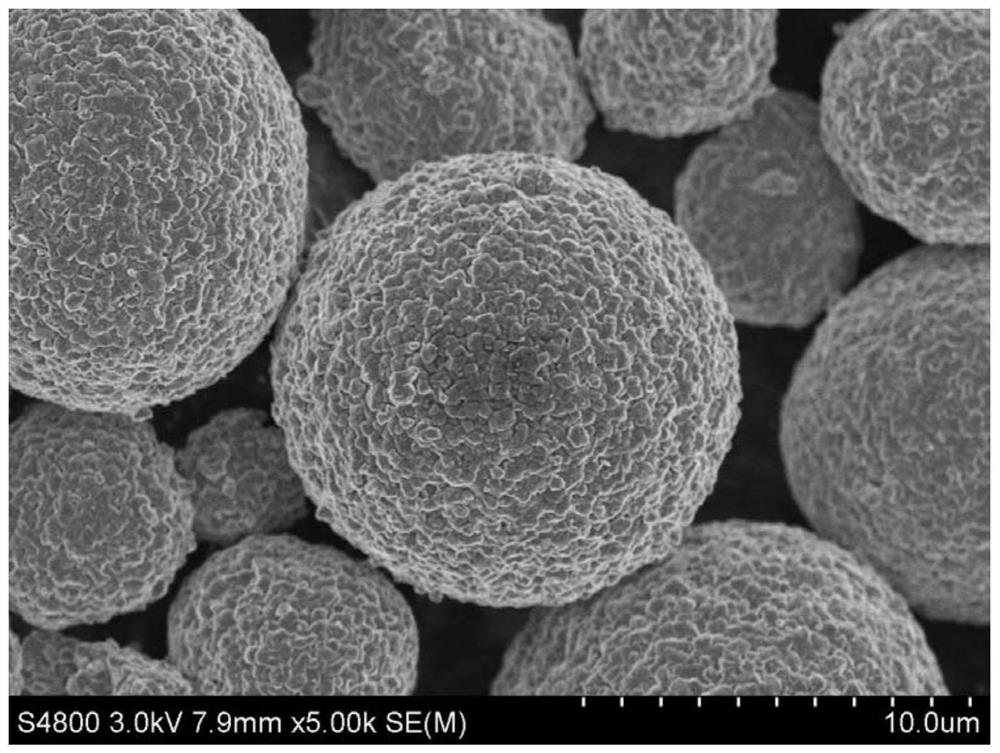

[0093] This embodiment provides a Li 6.5 Y 0.5 Zr 1.5 o 7 Coated boron-tungsten co-doped nickel-cobalt-manganese-aluminate positive electrode material and a preparation method thereof, the method comprising the following steps:

[0094] (1) A mixed solution containing nickel sulfate, cobalt sulfate and manganese sulfate with a metal ion concentration of 110g / L (the molar ratio of Ni, Co, and Mn is 8.9:0.7:0.4), 20g / L sodium metaaluminate solution, 100g / L The sodium carbonate solution and 5mol / L ammonia water were reacted at 60°C and the pH value was 11.0 to obtain the precursor.

[0095](2) Mix 20kg of the precursor obtained in step (1), 7.5kg of lithium carbonate, 185g of tungsten trioxide and 65 grams of boric acid, and sinter at 710°C for 10h to obtain the substrate; lithium ions in lithium carbonate and the precursor The molar ratio of nickel ions in is 1.06.

[0096] (3) Mix a certain molar ratio of lithium hydroxide, yttrium oxide and zirconium dioxide uniformly so ...

Embodiment 3

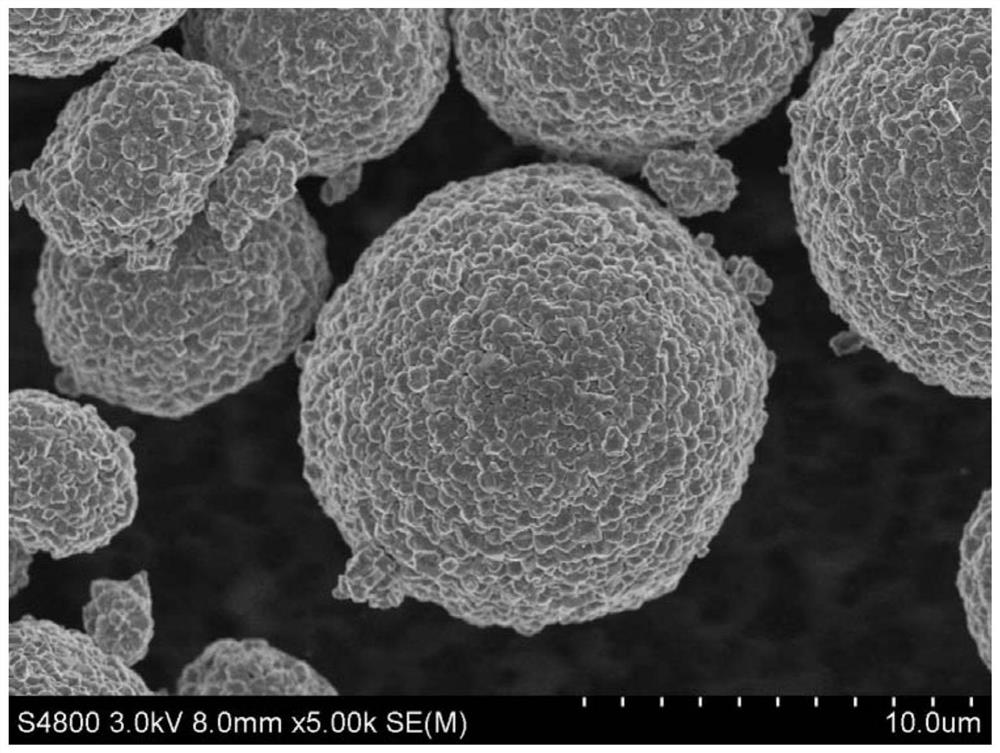

[0103] The embodiment provides a kind of Li 6.5 Y 0.5 Zr 1.5 o 7 Coated boron-tungsten co-doped nickel-cobalt-manganese-aluminate positive electrode material and a preparation method thereof, the method comprising the following steps:

[0104] (1) A mixed solution containing nickel sulfate, cobalt sulfate and manganese sulfate with a metal ion concentration of 110g / L (the molar ratio of Ni, Co, and Mn is 9.1:0.5:0.4), 30g / L sodium metaaluminate solution, 100g / L A sodium carbonate solution and 5mol / L ammonia water were reacted at 55°C and a pH value of 11.5 to obtain a precursor.

[0105] (2) Mix 20 kg of the precursor obtained in step (1), 8.5 kg of lithium hydroxide, 235 g of tungsten trioxide and 65 grams of boric acid, and sinter at 700 ° C for 10 hours to obtain the substrate; lithium ions in lithium hydroxide and The molar ratio of nickel ions in the precursor is 1.06.

[0106] (3) Mix a certain molar ratio of lithium hydroxide, yttrium oxide and zirconium dioxide un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median granularity | aaaaa | aaaaa |

| Median granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com