Efficient horizontal parting type removable flask molding machine and molding method thereof

A technology of horizontal parting and molding machines, which is applied in the direction of molding machines, manufacturing tools, casting molding equipment, etc., and can solve the problems of casting size and shape, difficulty in ensuring accuracy, large differences in compactness, and uneven distribution of cavity compactness. Uniformity and other issues to achieve good molding effect, high compaction uniformity, and uniform compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

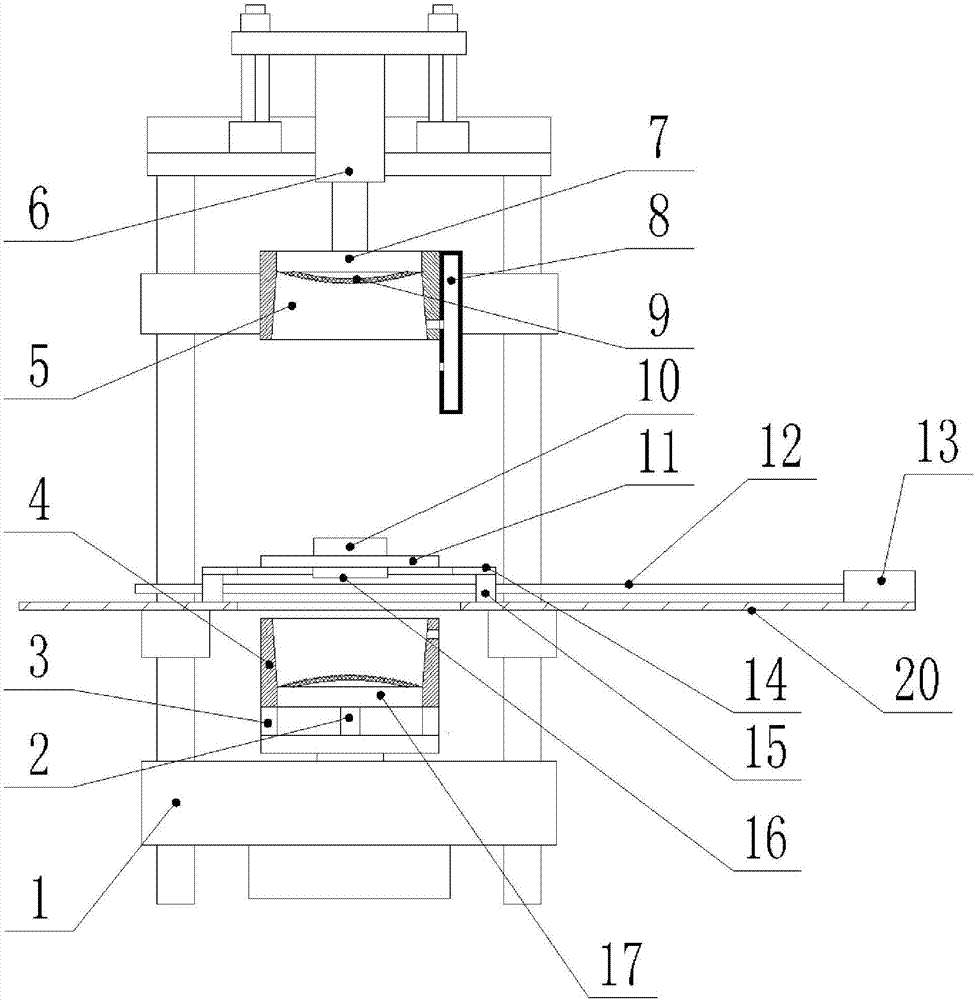

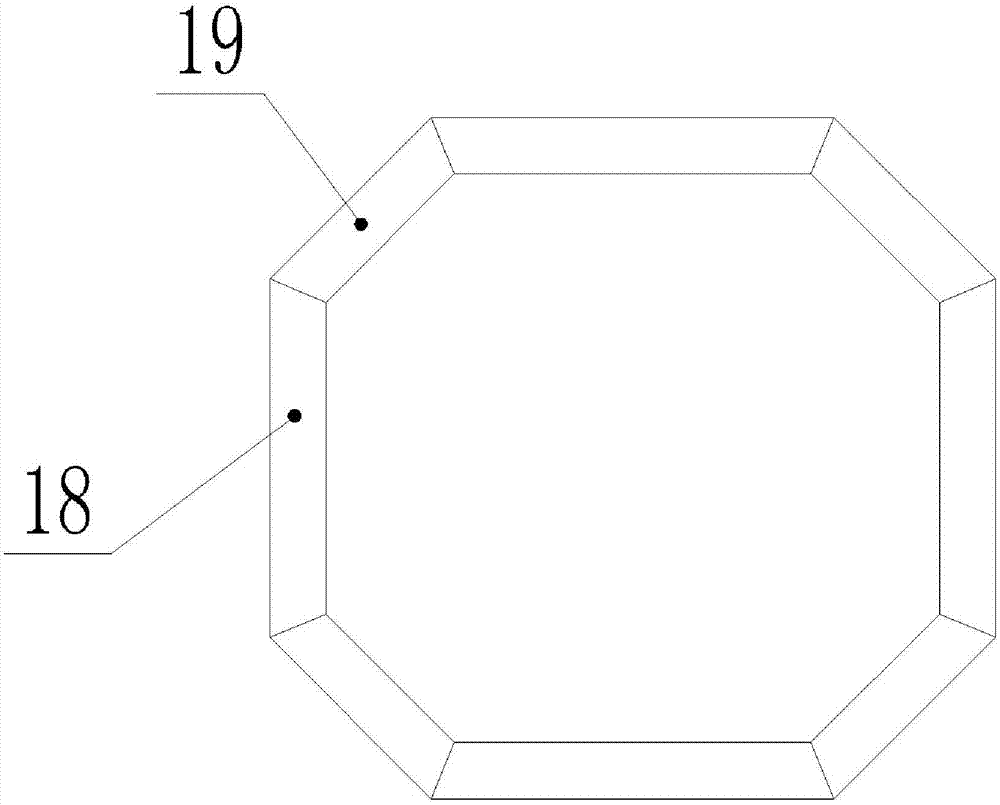

[0024] Such as figure 1 and figure 2 As shown, the high-efficiency horizontal splitting molding machine includes a frame 1, and the frame 1 is provided with a lower sand box module, and the lower sand box module includes a lower enclosure frame 4, which slides inside the lower enclosure frame 4. A lower push plate 17 is provided, and the lower frame 4 is connected with a first driving device 3 that drives it to move up and down; the lower push plate 17 is connected with a second drive device that drives it to move up and down relative to the lower frame 4 2. The frame 1 is provided with an upper sand box module positioned on the upper side of the lower sand box module, and the upper sand box module includes an upper enclosure frame 5 fixed on the frame 1, and the upper enclosure frame 5 An upper push plate 7 is slidably provided, and the upper push plate 7 is connected with a third driving device 6 for pushing it to move up and down. It also includes a sandblasting nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com