Testing device for concrete slump detection

A testing device and slump technology, applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems of unrealistic concrete uniformity, inability to achieve expansion and comprehensive compaction, and inability to achieve diversified detection, so as to facilitate detection Observing samples, realizing diversified detection, and realizing the effect of detection expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

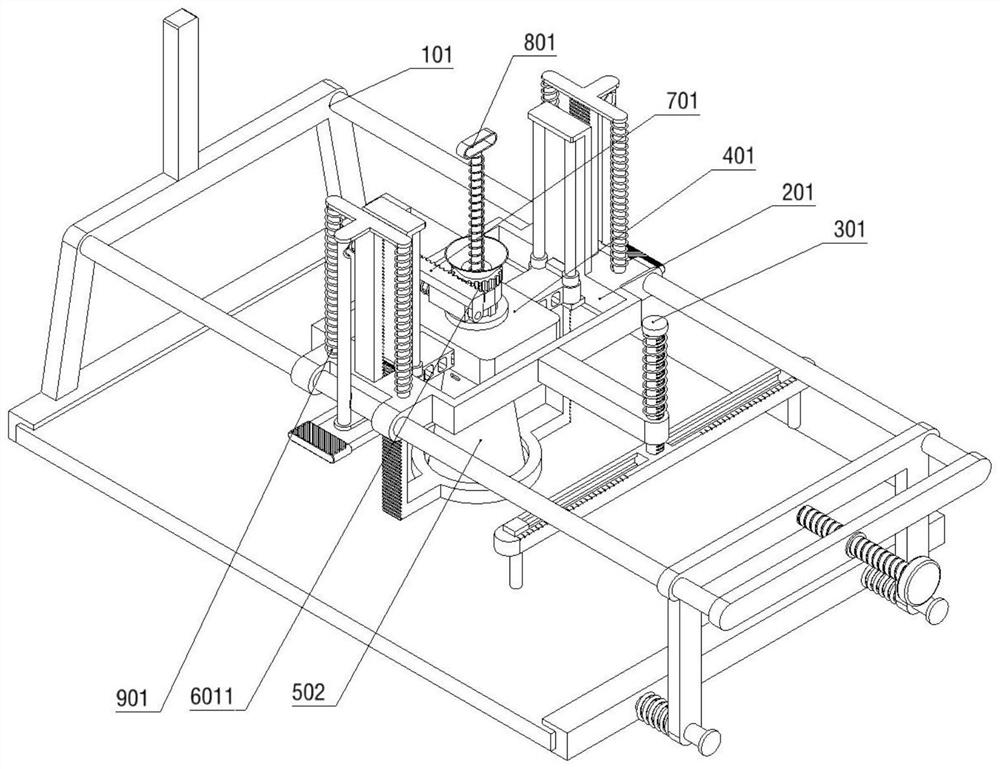

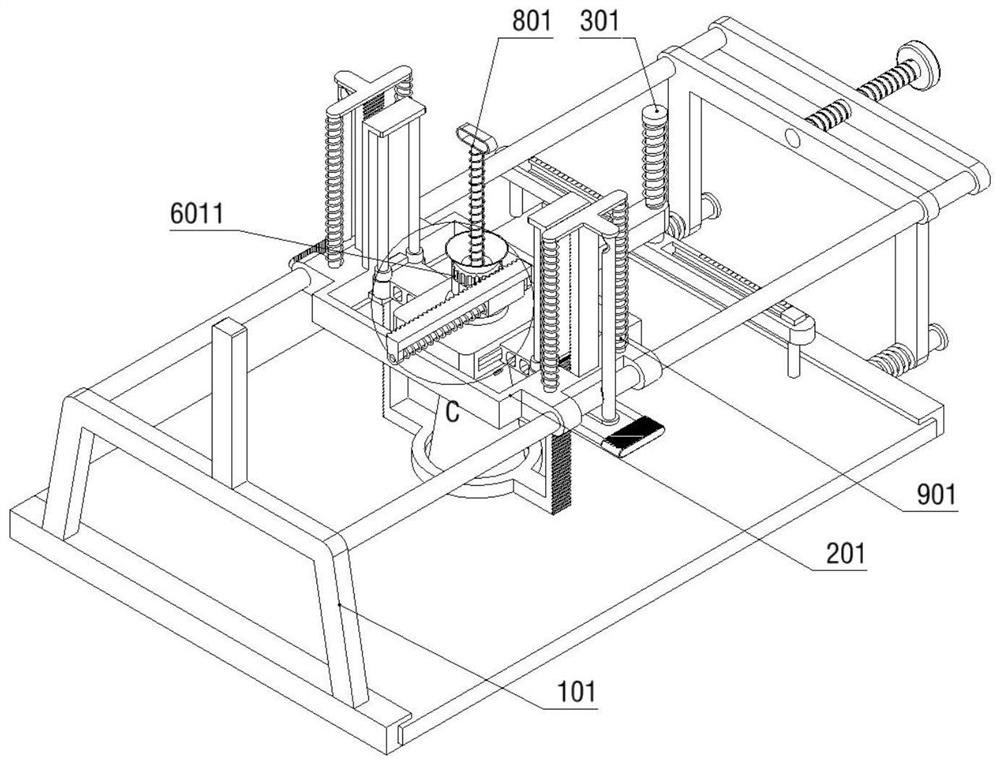

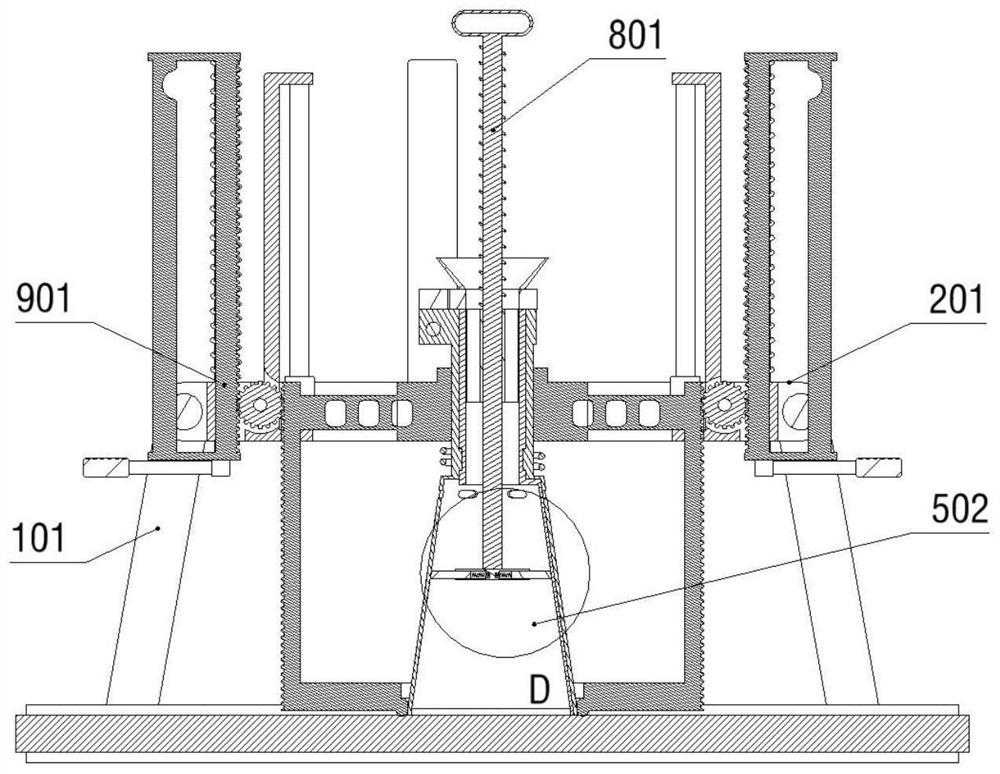

[0042] Example: please refer to Figure 1 to Figure 15 :

[0043] The present invention provides a test device for concrete slump detection, which includes an installation support part 1; a mobile propulsion device 2 is fixedly connected to the installation support part 1; a test device 3 is slidably connected to the mobile propulsion device 2; the mobile propulsion device 2 A floating drive part 4 is slidably connected on the floating drive part 4; a carrying device 5 is slidably connected on the floating drive part 4; a cleaning part 6 is rotatably connected on the carrying device 5; The expansion and compaction device 8; the moving propulsion device 2 is slidably connected with two stepping limit driving parts 9; the installation support part 1 includes: a clamping fixing frame 101, a fixing notch block 1011, a clamping sliding shaft 102, and a clamping installation rod 1021. Position the fixing rod 103 and the sliding push frame 104, the bottom of the clamping fixing fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com