Powder or granulated material test apparatus

A testing equipment, a technology for granular materials, applied in the preparation of samples for testing, analyzing materials, and testing the strength of materials using stable tension/pressure, which can solve problems such as limited applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

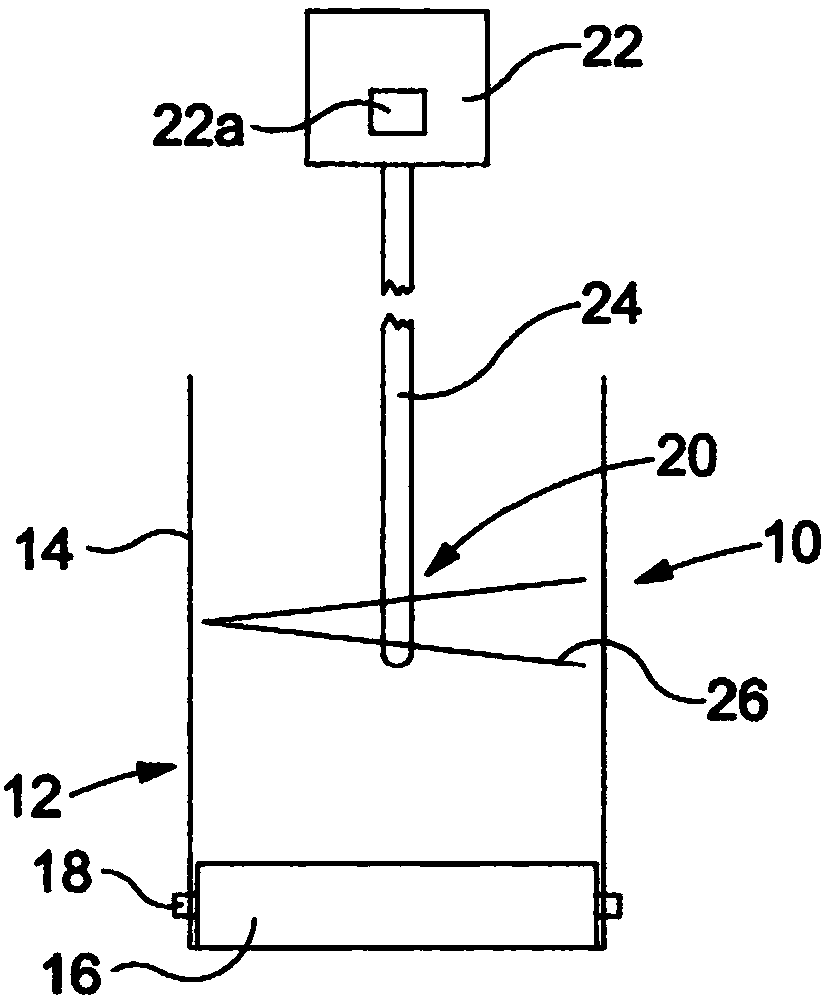

[0019] Referring to the drawings, a testing apparatus 10 is shown comprising a testing chamber 12 of generally cylindrical form. In the arrangement shown, the test chamber 12 takes the form of a hollow tubular member 14 within the lower end of which a table 16 is positioned, a fastening mechanism 18 is provided for releasably fastening the tubular member 14 Go to examination table 16. The inspection station 16 closes the end of the tubular member 14 and thus defines a container in which, in use, the material to be tested may be located. It should be understood, however, that this represents only one of a variety of possible designs from which test chamber 12 may be designed.

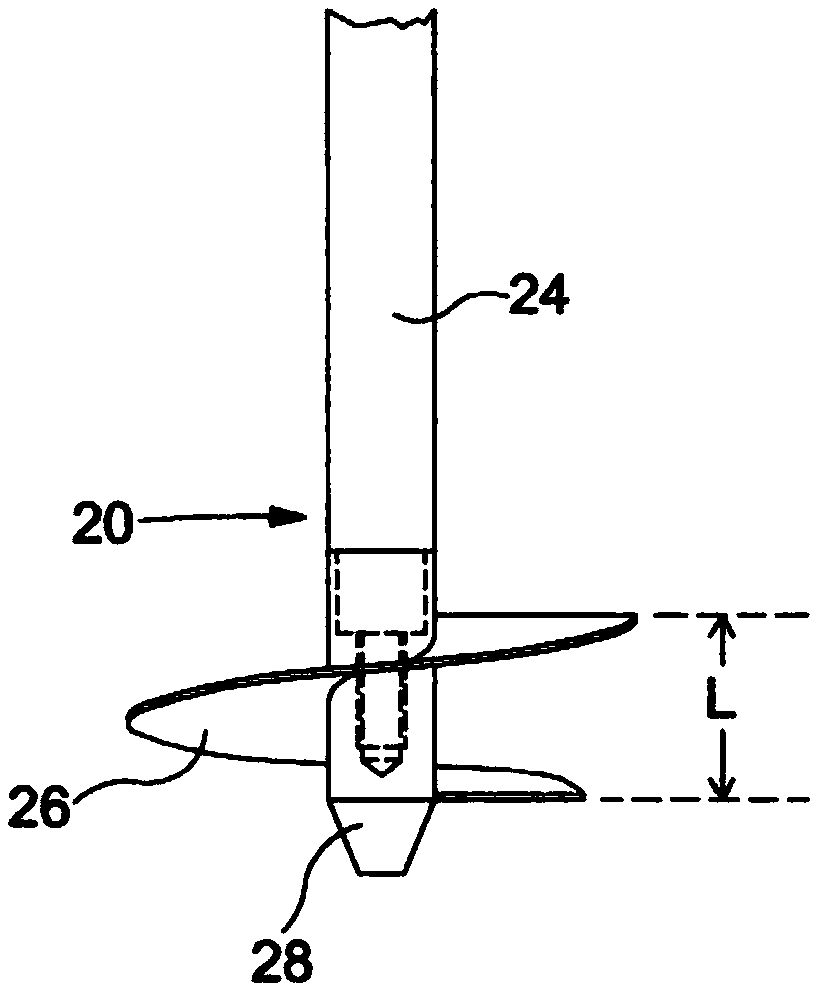

[0020] The apparatus 10 further comprises a powder handling device, hereinafter referred to for convenience as a compacting device 20, which can be introduced into the test chamber 12, can move axially along the length of the test chamber 12 and can also be driven for rotational movement around its axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com