A kind of anti-twist method for shaft tunneling

An anti-twist and vertical shaft technology, which is applied to shaft equipment, well sinking, earth-moving drilling, etc., can solve the problems of low reliability of shaft driving, easy rotation of shield body and segment, affecting driving efficiency, etc., so as to improve reliability and efficiency. The effect of excavation efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

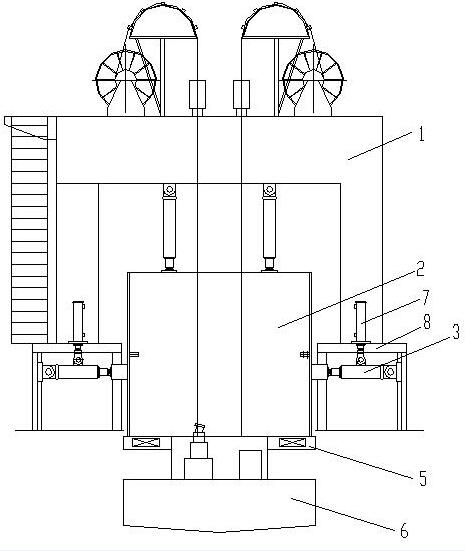

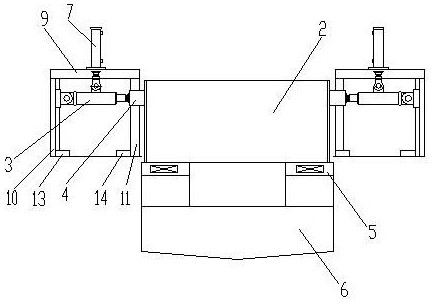

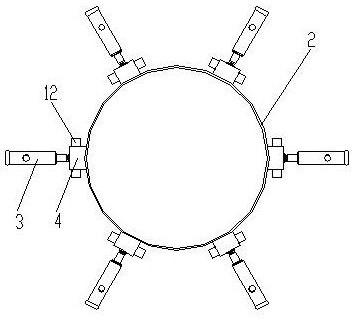

[0035] see Figure 1-Figure 3 , a shaft tunneling anti-twist method, comprising the following steps:

[0036] a. Wellhead excavation and foundation construction, install and fix the frame 1 of the roadheader on the ground plane, hoist the arc-shaped steel pipe sheets by a crane, and assemble and connect a plurality of arc-shaped steel pipe sheets to form a ring-shaped steel pipe 2;

[0037] b. The pressing mechanism works, the pressing oil cylinder 3 extends and pushes the friction pad 4 to the annular steel pipe 2 and compresses the outer wall of the annular steel tube 2. The friction pad 4 transmits the pressing force to the shield body 5, and the excavation is carried out. The cutter head 6 of the machine starts the excavation operation;

[0038] c. After the excavation operation is completed, the pressing oil cylinder 3 is retracted, the friction pad 4 is pulled away from the annular steel pipe 2, the reset oil cylinder 7 is retracted, the pressing oil cylinder 3 is lifte...

Embodiment 2

[0041] see Figure 1-Figure 3 , a shaft tunneling anti-twist method, comprising the following steps:

[0042] a. Wellhead excavation and foundation construction, install and fix the frame 1 of the roadheader on the ground plane, hoist the arc-shaped steel pipe sheets by a crane, and assemble and connect a plurality of arc-shaped steel pipe sheets to form a ring-shaped steel pipe 2;

[0043] b. The pressing mechanism works, the pressing oil cylinder 3 extends and pushes the friction pad 4 to the annular steel pipe 2 and compresses the outer wall of the annular steel tube 2. The friction pad 4 transmits the pressing force to the shield body 5, and the excavation is carried out. The cutter head 6 of the machine starts the excavation operation;

[0044] c. After the excavation operation is completed, the pressing oil cylinder 3 is retracted, the friction pad 4 is pulled away from the annular steel pipe 2, the reset oil cylinder 7 is retracted, the pressing oil cylinder 3 is lifte...

Embodiment 3

[0048] see Figure 1-Figure 3 , a shaft tunneling anti-twist method, comprising the following steps:

[0049] a. Wellhead excavation and foundation construction, install and fix the frame 1 of the roadheader on the ground plane, hoist the arc-shaped steel pipe sheets by a crane, and assemble and connect a plurality of arc-shaped steel pipe sheets to form a ring-shaped steel pipe 2;

[0050] b. The pressing mechanism works, the pressing oil cylinder 3 extends and pushes the friction pad 4 to the annular steel pipe 2 and compresses the outer wall of the annular steel tube 2. The friction pad 4 transmits the pressing force to the shield body 5, and the excavation is carried out. The cutter head 6 of the machine starts the excavation operation;

[0051] c. After the excavation operation is completed, the pressing oil cylinder 3 is retracted, the friction pad 4 is pulled away from the annular steel pipe 2, the reset oil cylinder 7 is retracted, the pressing oil cylinder 3 is lifte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com